Woodworker's Journal 1984-8-2, страница 46

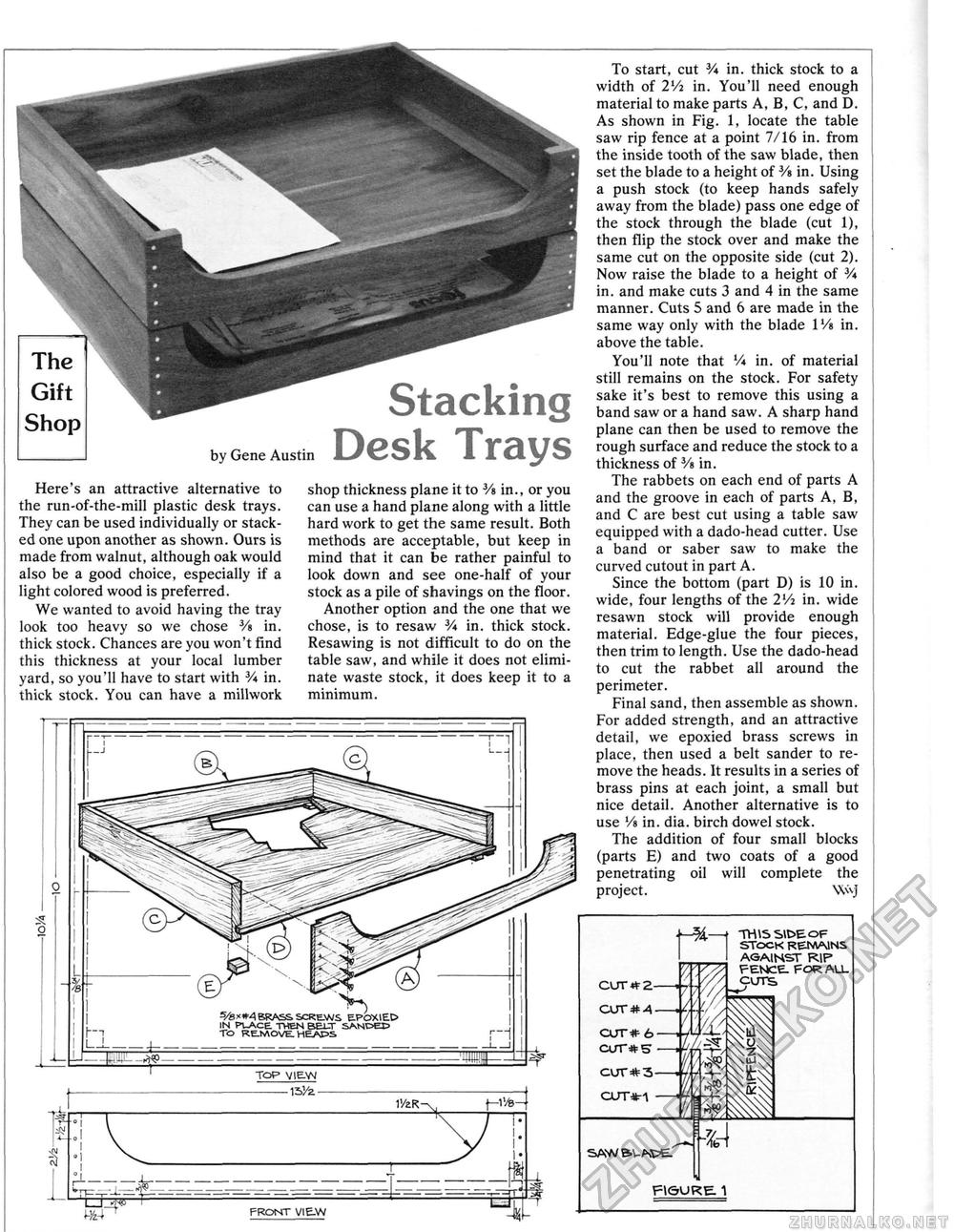

by Gene Austin Stacking Desk Trays Here's an attractive alternative to the run-of-the-mill plastic desk trays. They can be used individually or stacked one upon another as shown. Ours is made from walnut, although oak would also be a good choice, especially if a light colored wood is preferred. We wanted to avoid having the tray look too heavy so we chose 3/s in. thick stock. Chances are you won't find this thickness at your local lumber yard, so you'll have to start with 3A in. thick stock. You can have a millwork shop thickness plane it to Vz in., or you can use a hand plane along with a little hard work to get the same result. Both methods are acceptable, but keep in mind that it can be rather painful to look down and see one-half of your stock as a pile of shavings on the floor. Another option and the one that we chose, is to resaw V* in, thick stock. Resawing is not difficult to do on the table saw, and while it does not eliminate waste stock, it does keep it to a minimum. I-! I__ s/a*#A BRASS SCRE.WS EPOXIED IN PV-ACE. TrtcN BELT SANDB5 TO R6.MOVEH6ADS ■L.11J-.U.1. -ft---------------------- " TOP VIEW -------------— J=f I'/ER j-lVfc- To start, cut 3A in. thick stock to a width of 2Vi in. You'll need enough material to make parts A, B, C, and D. As shown in Fig. 1, locate the table saw rip fence at a point 7/16 in. from the inside tooth of the saw blade, then set the blade to a height of 3/e in. Using a push stock (to keep hands safely away from the blade) pass one edge of the stock through the blade (cut 1), then flip the stock over and make the same cut on the opposite side (cut 2). Now raise the blade to a height of V* in. and make cuts 3 and 4 in the same manner. Cuts S and 6 are made in the same way only with the blade l'/» in. above the table. You'll note that V* in. of material still remains on the stock. For safety sake it's best to remove this using a band saw or a hand saw, A sharp hand plane can then be used to remove the rough surface and reduce the stock to a thickness of Vs in. The rabbets on each end of parts A and the groove in each of parts A, B, and C are best cut using a table saw equipped with a dado-head cutter. Use a band or saber saw to make the curved cutout in part A. Since the bottom (part D) is 10 in. wide, four lengths of the 2Vt in. wide resawn stock will provide enough material. Edge-glue the four pieces, then trim to length. Use the dado-head to cut the rabbet all around the perimeter. Final sand, then assemble as shown. For added strength, and an attractive detail, we epoxied brass screws in place, then used a belt sander to remove the heads. It results in a series of brass pins at each joint, a small but nice detail. Another alternative is to use V% in. dia. birch dowel stock. The addition of four small blocks (parts E) and two coats of a good penetrating oil will complete the project. W'vf FRONT VIEW THIS SIDE OF STOCK REMAINS AGAINST RIP FENCE- FOR ALL CUTE, CUT* 6 CUT#S cur* 3—4-, sAW&uwpe. R&URE. 1 |