Woodworker's Journal 1984-8-2, страница 50

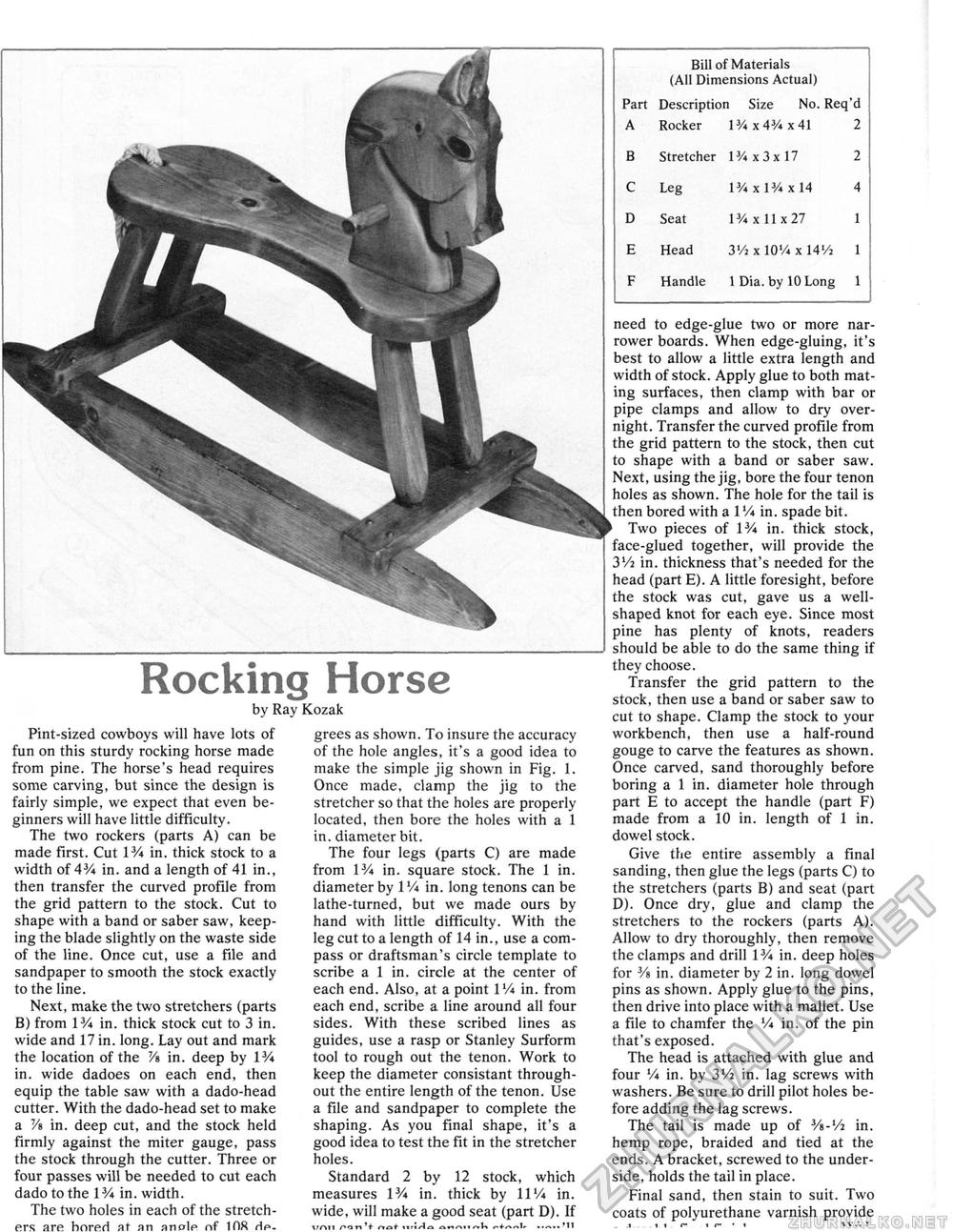

Bill of Materials (All Dimensions Actual) Part Description Size No. Req'd A Rocker l3A x 43A x 41 2 C Leg 13A xl3A x 14 4 D Seat VAx 11x27 1 E Head 3l/i x W1/i x 14'/j 1 Stretcher iy*x3xl7 2 need to edge-glue two or more narrower boards. When edge-gluing, it's best to allow a little extra length and width of stock. Apply glue to both mating surfaces, then clamp with bar or pipe clamps and allow to dry overnight. Transfer the curved profile from the grid pattern to the stock, then cut to shape with a band or saber saw. Next, using the jig, bore the four tenon holes as shown. The hole for the tail is then bored with a 1Vi in. spade bit. Two pieces of IV* in. thick stock, face-glued together, will provide the 3'/i in. thickness that's needed for the head (part E). A little foresight, before the stock was cut, gave us a well-shaped knot for each eye. Since most pine has plenty of knots, readers should be able to do the same thing if they choose. Transfer the grid pattern to the stock, then use a band or saber saw to cut to shape. Clamp the stock to your workbench, then use a half-round gouge to carve the features as shown. Once carved, sand thoroughly before boring a 1 in. diameter hole through part E to accept the handle (part F) made from a 10 in. length of 1 in. dowel stock. Give the entire assembly a final sanding, then glue the legs (parts C) to the stretchers (parts B) and seat (part D). Once dry, glue and clamp the stretchers to the rockers (parts A). Allow to dry thoroughly, then remove the clamps and drill IV* in. deep holes for V» in. diameter by 2 in. long dowel pins as shown. Apply glue to the pins, then drive into place with a mallet. Use a file to chamfer the Vi in. of the pin that's exposed. The head is attached with glue and four V* in. by 3Vj in. lag screws with washers. Be sure to drill pilot holes before adding the lag screws. The tail is made up of Vt-Vi in. hemp rope, braided and tied at the ends. A bracket, screwed to the underside, holds the tail in place. Final sand, then stain to suit. Two coats of polyurethane varnish provide J 11 (- 1 C * 1 IV.'. 3 Rocking Horse by Ray Kozak Pint-sized cowboys will have lots of fun on this sturdy rocking horse made from pine. The horse's head requires some carving, but since the design is fairly simple, we expect that even beginners will have little difficulty. The two rockers (parts A) can be made first. Cut l3/i in. thick stock to a width of 43A in. and a length of 41 in., then transfer the curved profile from the grid pattern to the stock. Cut to shape with a band or saber saw, keeping the blade slightly on the waste side of the line. Once cut, use a file and sandpaper to smooth the stock exactly to the line. Next, make the two stretchers (parts B) from 13A in. thick stock cut to 3 in. wide and 17 in. long. Lay out and mark the location of the Vs in. deep by IV* in. wide dadoes on each end, then equip the table saw with a dado-head cutter. With the dado-head set to make a Vs in. deep cut, and the stock held firmly against the miter gauge, pass the stock through the cutter. Three or four passes will be needed to cut each dado to the 1V* in. width. The two holes in each of the stretchers are horerl at an anolr1 nf IflR Hp. grees as shown. To insure the accuracy of the hole angles, it's a good idea to make the simple jig shown in Fig. 1. Once made, clamp the jig to the stretcher so that the holes are properly located, then bore the holes with a 1 in. diameter bit. The four legs (parts C) are made from IV* in. square stock. The 1 in. diameter by 1 Vi in. long tenons can be lathe-turned, but we made ours by hand with little difficulty. With the leg cut to a length of 14 in., use a compass or draftsman's circle template to scribe a 1 in. circle at the center of each end. Also, at a point 1 Vi in. from each end, scribe a line around all four sides. With these scribed lines as guides, use a rasp or Stanley Surform tool to rough out the tenon. Work to keep the diameter consistant throughout the entire length of the tenon. Use a file and sandpaper to complete the shaping. As you final shape, it's a good idea to test the fit in the stretcher holes. Standard 2 by 12 stock, which measures 13A in. thick by 11 Vi in. %vide, will make a good seat (part D). If unit pon'f rrjaf itfJ/Iq Qti/Mi /yU >■"••''1 |