Woodworker's Journal 1984-8-3, страница 33

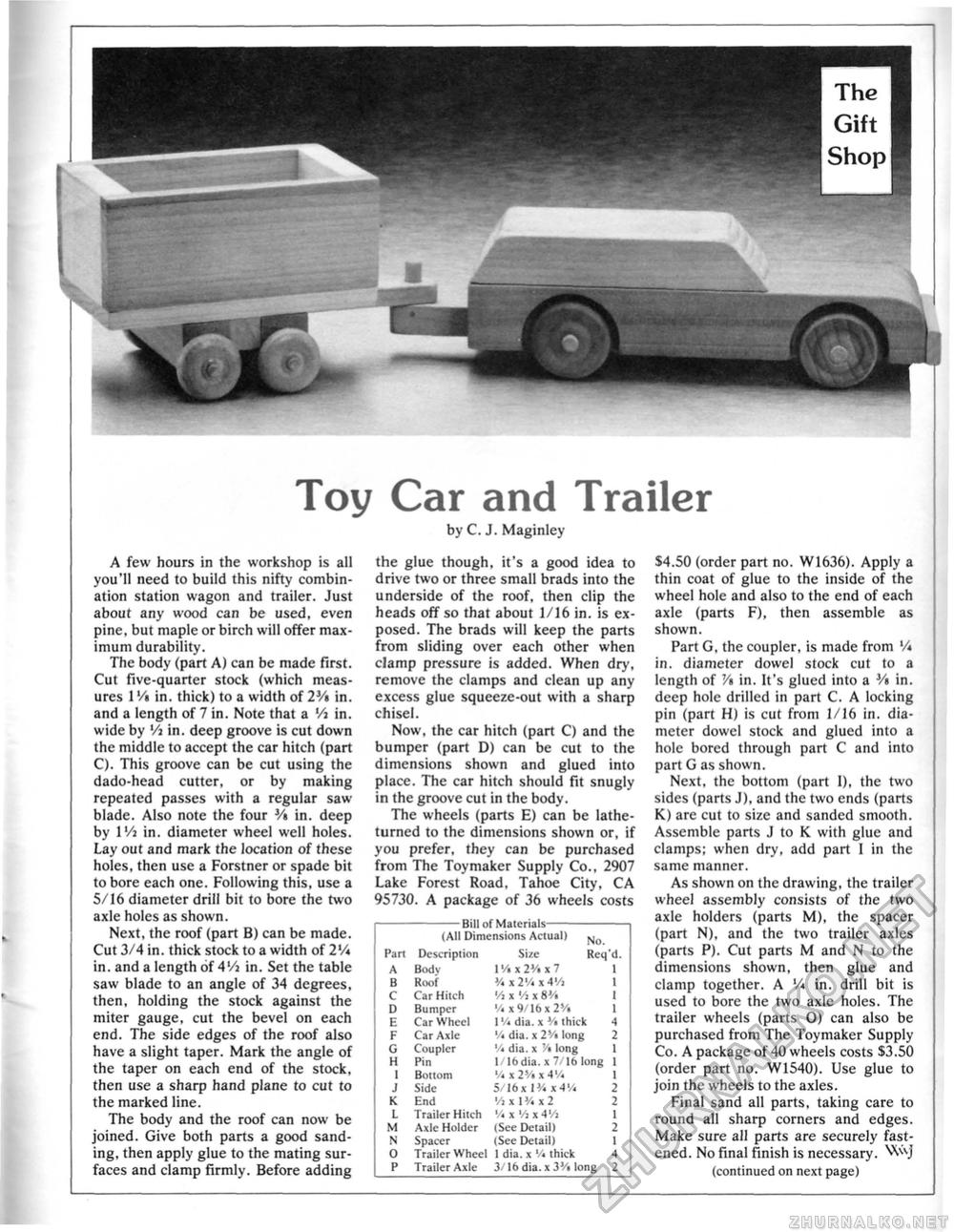

Toy Car and Trailer by C. J. Maginley A few hours in the workshop is all you'll need to build this nifty combination station wagon and trailer. Just about any wood can be used, even pine, but maple or birch will offer maximum durability. The body (part A) can be made first. Cut five-quarter stock (which measures 1'/« in. thick) to a width of 23/» in. and a length of 7 in. Note that a Vi in. wide by Vi in. deep groove is cut down the middle to accept the car hitch (part C). This groove can be cut using the dado-head cutter, or by making repeated passes with a regular saw blade. Also note the four lA in. deep by IVi in. diameter wheel well holes. Lay out and mark the location of these holes, then use a Forstner or spade bit to bore each one. Following this, use a 5/16 diameter drill bit to bore the two axle holes as shown. Next, the roof (part B) can be made. Cut 3/4 in. thick stock to a width of 2'/« in. and a length of 4'/i in. Set the table saw blade to an angle of 34 degrees, then, holding the stock against the miter gauge, cut the bevel on each end. The side edges of the roof also have a slight taper. Mark the angle of the taper on each end of the stock, then use a sharp hand plane to cut to the marked line. The body and the roof can now be joined. Give both parts a good sanding, then apply glue to the mating surfaces and clamp firmly. Before adding the glue though, it's a good idea to drive two or three small brads into the underside of the roof, then clip the heads off so that about 1/16 in. is exposed. The brads will keep the parts from sliding over each other when clamp pressure is added. When dry, remove the clamps and clean up any excess glue squeeze-out with a sharp chisel. Now, the car hitch (part C) and the bumper (part D) can be cut to the dimensions shown and glued into place. The car hitch should fit snugly in the groove cut in the body. The wheels (parts E) can be lathe-turned to the dimensions shown or, if you prefer, they can be purchased from The Toy maker Supply Co., 2907 Lake Forest Road, Tahoe City, CA 95730. A package of 36 wheels costs -Bill of Materials- (All Dimensions Actual) N(J -Bill of Materials- (All Dimensions Actual) N(J

$4.50 (order part no. W1636). Apply a thin coat of glue to the inside of the wheel hole and also to the end of each axle (parts F), then assemble as shown. Part G, the coupler, is made from V* in. diameter dowel stock cut to a length of V» in. It's glued into a Vt in. deep hole drilled in part C. A locking pin (part H) is cut from 1/16 in. diameter dowel stock and glued into a hole bored through part C and into part G as shown. Next, the bottom (part I), the two sides (parts J), and the two ends (parts K) are cut to size and sanded smooth. Assemble parts J to K with glue and clamps; when dry, add part 1 in the same manner. As shown on the drawing, the trailer wheel assembly consists of the two axle holders (parts M), the spacer (part N), and the two trailer axles (parts P). Cut parts M and N to the dimensions shown, then glue and clamp together, A '/« in. drill bit is used to bore the two axle holes. The trailer wheels (parts O) can also be purchased from The Toymaker Supply Co. A package of 40 wheels costs $3.50 (order part no. W1540). Use glue to join the wheels to the axles. Final sand all parts, taking care to round all sharp corners and edges. Make sure all parts are securely fastened. No final finish is necessary. Wvj (continued on next page) |