Woodworker's Journal 1984-8-3, страница 40

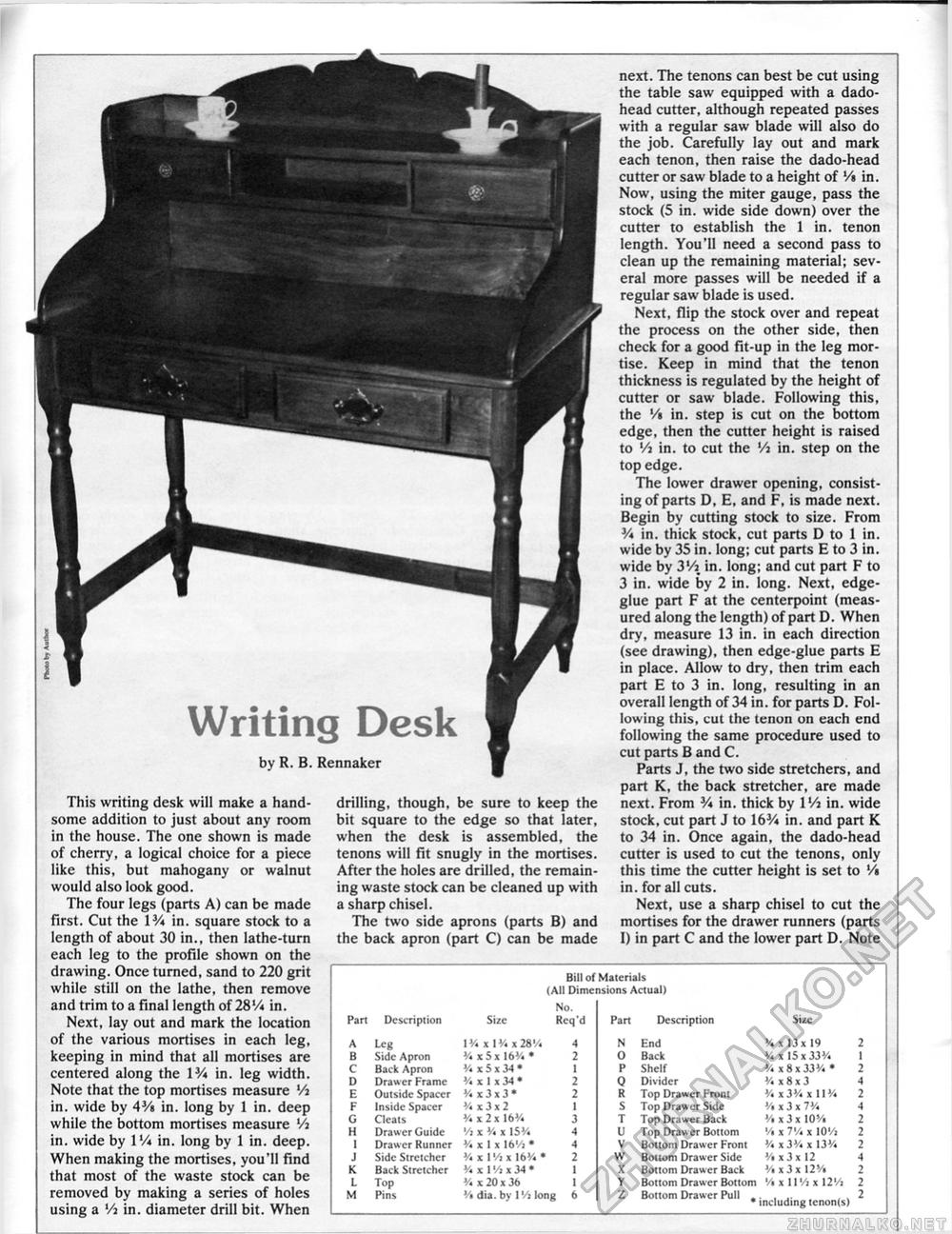

Writing Desk by R. B. Rennaker This writing desk will make a handsome addition to just about any room in the house. The one shown is made of cherry, a logical choice for a piece like this, but mahogany or walnut would also look good. The four legs (parts A) can be made first. Cut the IV* in. square stock to a length of about 30 in., then lathe-turn each leg to the profile shown on the drawing. Once turned, sand to 220 grit while still on the lathe, then remove and trim to a final length of 28Vi in. Next, lay out and mark the location of the various mortises in each leg, keeping in mind that all mortises are centered along the l3/« in. leg width. Note that the top mortises measure Vi in. wide by 43/« in. long by 1 in. deep while the bottom mortises measure Vi in. wide by IV* in. long by 1 in. deep. When making the mortises, you'll find that most of the waste stock can be removed by making a series of holes using a Vi in. diameter drill bit. When drilling, though, be sure to keep the bit square to the edge so that later, when the desk is assembled, the tenons will fit snugly in the mortises. After the holes are drilled, the remaining waste stock can be cleaned up with a sharp chisel. The two side aprons (parts B) and the back apron (part C) can be made next. The tenons can best be cut using the table saw equipped with a dado-head cutter, although repeated passes with a regular saw blade will also do the job. Carefully lay out and mark each tenon, then raise the dado-head cutter or saw blade to a height of V» in. Now, using the miter gauge, pass the stock (5 in. wide side down) over the cutter to establish the 1 in. tenon length. You'll need a second pass to clean up the remaining material; several more passes will be needed if a regular saw blade is used. Next, flip the stock over and repeat the process on the other side, then check for a good fit-up in the leg mortise. Keep in mind that the tenon thickness is regulated by the height of cutter or saw blade. Following this, the '/» in. step is cut on the bottom edge, then the cutter height is raised to Vi in. to cut the Vi in. step on the top edge. The lower drawer opening, consisting of parts D, E, and F, is made next. Begin by cutting stock to size. From V* in. thick stock, cut parts D to 1 in. wide by 35 in. long; cut parts E to 3 in. wide by 3Vi in. long; and cut part F to 3 in. wide by 2 in. long. Next, edge-glue part F at the centerpoint (measured along the length) of part D. When dry, measure 13 in. in each direction (see drawing), then edge-glue parts E in place. Allow to dry, then trim each part E to 3 in. long, resulting in an overall length of 34 in. for parts D. Following this, cut the tenon on each end following the same procedure used to cut parts B and C. Parts J, the two side stretchers, and part K, the back stretcher, are made next. From V* in. thick by l'/i in. wide stock, cut part J to 163/* in. and part K to 34 in. Once again, the dado-head cutter is used to cut the tenons, only this time the cutter height is set to '/« in. for all cuts. Next, use a sharp chisel to cut the mortises for the drawer runners (parts I) in part C and the lower part D. Note Bill of Materials (All Dimensions Actual) No. Bill of Materials (All Dimensions Actual) No.

|