Woodworker's Journal 1984-8-4, страница 16

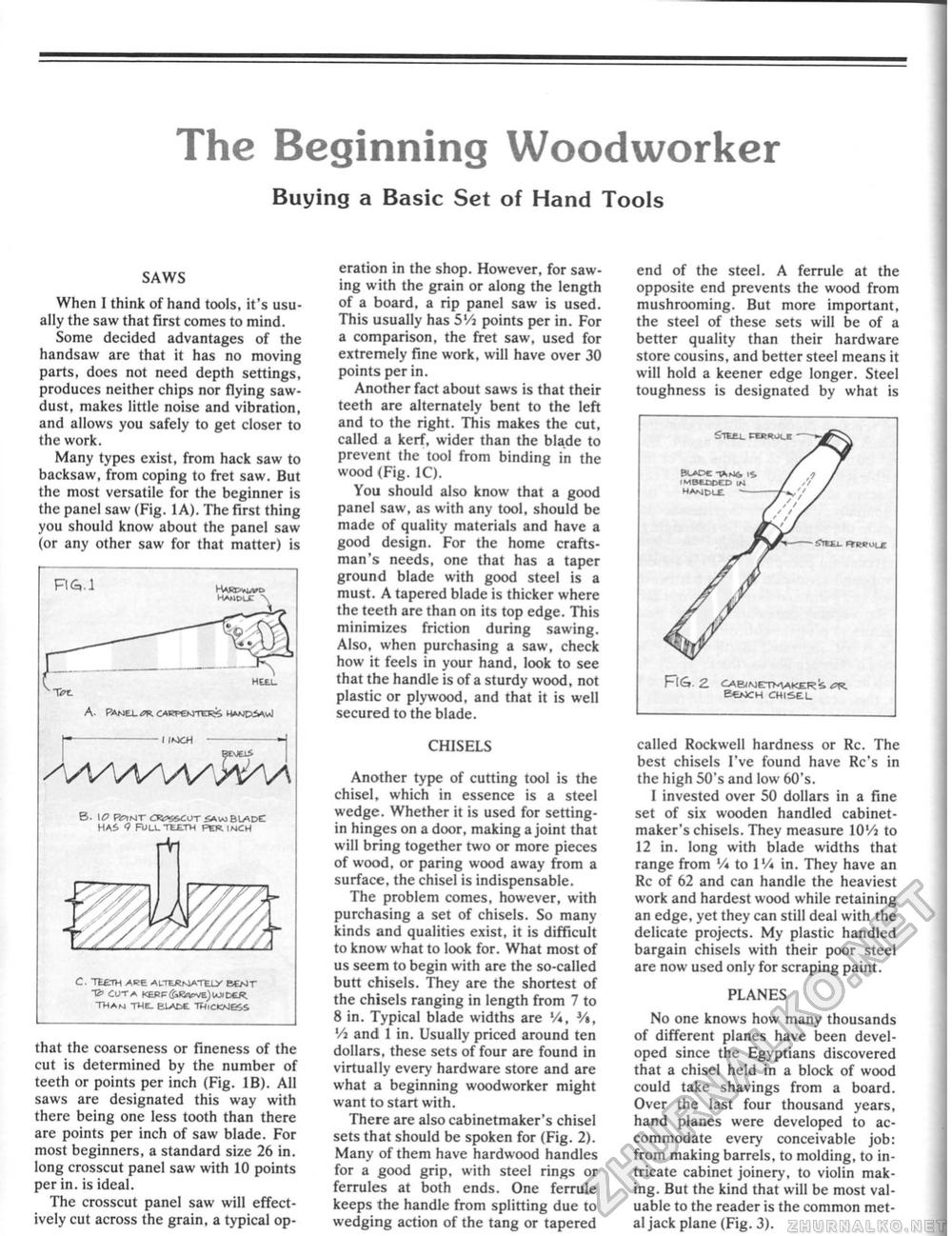

The Beginning Woodworker Buying a Basic Set of Hand Tools SAWS When I think of hand tools, it's usually the saw that first comes to mind. Some decided advantages of the handsaw are that it has no moving parts, does not need depth settings, produces neither chips nor flying sawdust, makes little noise and vibration, and allows you safely to get closer to the work. Many types exist, from hack saw to backsaw, from coping to fret saw. But the most versatile for the beginner is the panel saw (Fig. 1 A). The first thing you should know about the panel saw (or any other saw for that matter) is Ft <=».! A. PANEL ^oEpgM-fERfe HAAJO^W! p-IIMCH ------—>-j B. IO Rp|MT CKi*Sf-COT 5AV0 BL*n>e HAS 9 FULL TKETH PER. iwCH C. TL£TH APE *L-rtRh4AT&l_y BEfJT "E> CUT A KERF&f&WE^UJlDER THAm THE. fcLAue TftictCMESS that the coarseness or fineness of the cut is determined by the number of teeth or points per inch (Fig. IB). All saws are designated this way with there being one less tooth than there are points per inch of saw blade. For most beginners, a standard size 26 in. long crosscut panel saw with 10 points per in. is ideal. The crosscut panel saw will effectively cut across the grain, a typical op eration in the shop. However, for sawing with the grain or along the length of a board, a rip panel saw is used. This usually has 5'/j points per in. For a comparison, the fret saw. used for extremely fine work, will have over 30 points per in. Another fact about saws is that their teeth are alternately bent to the left and to the right. This makes the cut, called a kerf, wider than the blade to prevent the tool from binding in the wood {Fig. 1C). You should also know that a good panel saw, as with any tool, should be made of quality materials and have a good design. For the home craftsman's needs, one that has a taper ground blade with good steel is a must. A tapered blade is thicker where the teeth are than on its top edge. This minimizes friction during sawing. Also, when purchasing a saw, check how it feels in your hand, look to see that the handle is of a sturdy wood, not plastic or plywood, and that it is well secured to the blade. CHISELS Another type of cutting tool is the chisel, which in essence is a steel wedge. Whether it is used for setting-in hinges on a door, making a joint that will bring together two or more pieces of wood, or paring wood away from a surface, the chisel is indispensable. The problem comes, however, with purchasing a set of chisels. So many kinds and qualities exist, it is difficult to know w hat to look for. What most of us seem to begin with are the so-called butt chisels. They are the shortest of the chisels ranging in length from 7 to 8 in. Typical blade widths are lA, Vi, Vi and 1 in. Usually priced around ten dollars, these sets of four are found in virtually every hardware store and are what a beginning woodworker might want to start with. There are also cabinetmaker's chisel sets that should be spoken for (Fig. 2). Many of them have hardwood handles for a good grip, with steel rings or ferrules at both ends. One ferrule keeps the handle from splitting due to wedging action of the tang or tapered end of the steel. A ferrule at the opposite end prevents the wood from mushrooming. But more important, the steel of these sets will be of a better quality than their hardware store cousins, and better steel means it will hold a keener edge longer. Steel toughness is designated by what is SlEtl. cebrjle "•lOtWlED IP) HA*it>l_E FIG. 2 OVBJMETM^KER^ GO, CHISEL called Rockwell hardness or Rc. The best chisels I've found have Re's in the high 50's and low 60's. 1 invested over 50 dollars in a fine set of six wooden handled cabinetmaker's chisels. They measure lOVi to 12 in. long with blade widths that range from V* to IV* in. They have an Rc of 62 and can handle the heaviest work and hardest wood while retaining an edge, yet they can still deal with the delicate projects. My plastic handled bargain chisels with their poor steel are now used only for scraping paint. PLANES No one knows how many thousands of different planes have been developed since the Egyptians discovered that a chisel held in a block of wood could take shavings from a board. Over the last four thousand years, hand planes were developed to accommodate every conceivable job: from making barrels, to molding, to intricate cabinet joinery, to violin making. But the kind that will be most valuable to the reader is the common metal jack plane (Fig. J). |