Woodworker's Journal 1984-8-4, страница 17

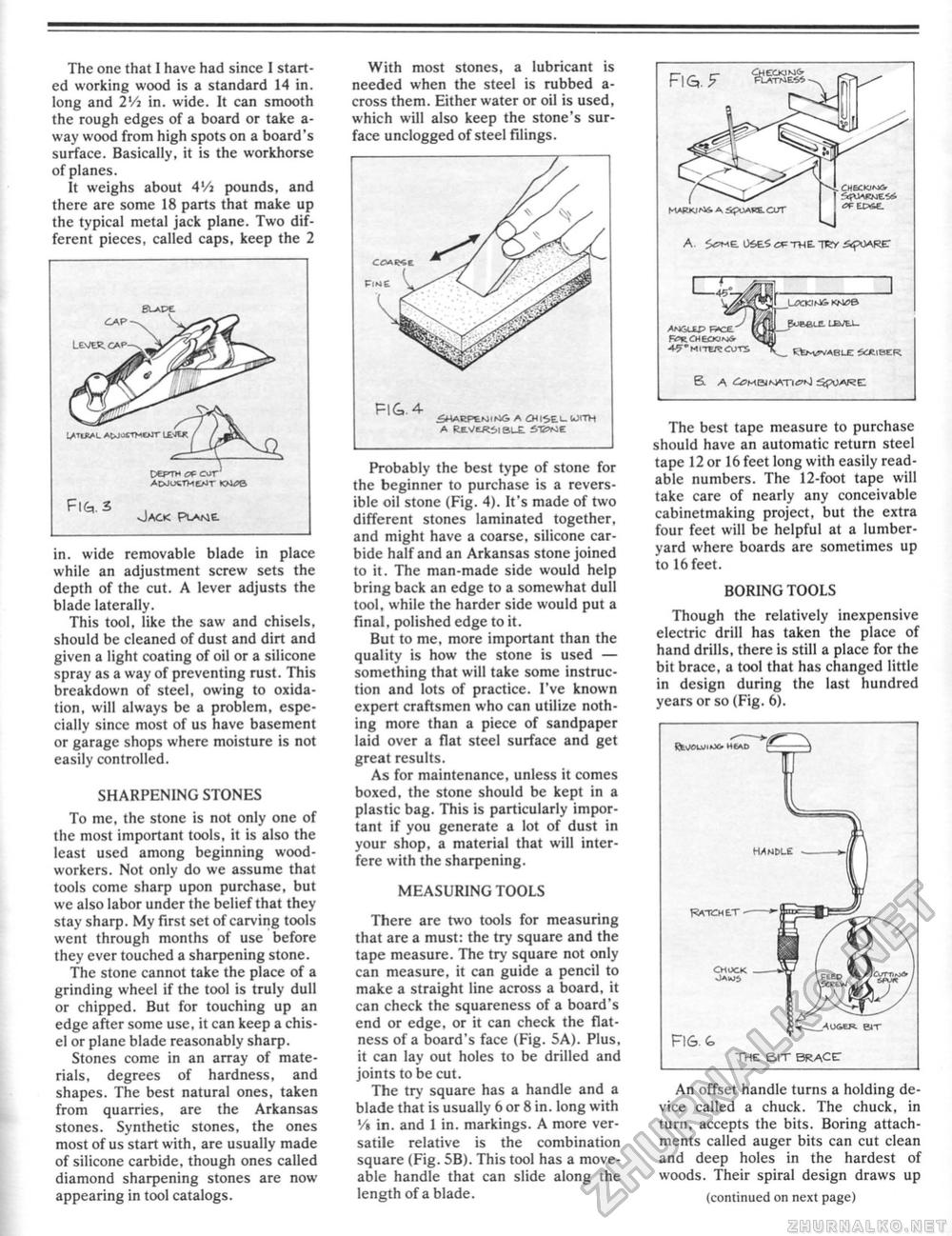

The one that 1 have had since I started working wood is a standard 14 in. long and 2'/i in. wide. It can smooth the rough edges of a board or take away wood from high spots on a board's surface. Basically, it is the workhorse of planes. It weighs about 4'/j pounds, and there are some 18 pans that make up the typical metal jack plane. Two different pieces, called caps, keep the 2

in. wide removable blade in place while an adjustment screw sets the depth of the cut. A lever adjusts the blade laterally. This tool, like the saw and chisels, should be cleaned of dust and dirt and given a light coating of oil or a silicone spray as a way of preventing rust. This breakdown of steel, owing to oxidation, will always be a problem, especially since most of us have basement or garage shops where moisture is not easily controlled. SHARPENING STONES To me, the stone is not only one of the most important tools, it is also the least used among beginning woodworkers. Not only do we assume that tools come sharp upon purchase, but we also labor under the belief that they stay sharp. My first set of carving tools went through months of use before they ever touched a sharpening stone. The stone cannot take the place of a grinding wheel if the tool is truly dull or chipped. But for touching up an edge after some use, it can keep a chisel or plane blade reasonably sharp. Stones come in an array of materials, degrees of hardness, and shapes. The best natural ones, taken from quarries, are the Arkansas stones. Synthetic stones, the ones most of us start with, are usually made of silicone carbide, though ones called diamond sharpening stones are now appearing in tool catalogs. With most stones, a lubricant is needed when the steel is rubbed across them. Either water or oil is used, which will also keep the stone's surface unclogged of steel filings.

Probably the best type of stone for the beginner to purchase is a reversible oil stone (Fig. 4). It's made of two different stones laminated together, and might have a coarse, silicone carbide half and an Arkansas stone joined to it. The man-made side would help bring back an edge to a somewhat dull tool, while the harder side would put a finat, polished edge to it. But to me, more important than the quality is how the stone is used — something that will take some instruction and lots of practice. I've known expert craftsmen who can utilize nothing more than a piece of sandpaper laid over a flat steel surface and get great results. As for maintenance, unless it comes boxed, the stone should be kept in a plastic bag. This is particularly important if you generate a lot of dust in your shop, a material that will interfere with the sharpening. MEASURING TOOLS There are two tools for measuring that are a must: the try square and the tape measure. The try square not only can measure, it can guide a pencil to make a straight line across a board, it can check the squareness of a board's end or edge, or it can check the flatness of a board's face (Fig. 5A). Plus, it can lay out holes to be drilled and joints to be cut. The try square has a handle and a blade that is usually 6 or 8 in. long with Vt in. and I in. markings. A more versatile relative is the combination square (Fig. 5B). This tool has a moveable handle that can slide along the length of a blade. The best tape measure to purchase should have an automatic return steel tape 12 or 16 feet long with easily readable numbers. The 12-foot tape will take care of nearly any conceivable cabinetmaking project, but the extra four feet will be helpful at a lumberyard where boards are sometimes up to 16 feet. BORING TOOLS Though the relatively inexpensive electric drill has taken the place of hand drills, there is still a place for the bit brace, a tool that has changed little in design during the last hundred years or so (Fig. 6). An offset handle turns a holding device called a chuck. The chuck, in turn, accepts the bits. Boring attachments called auger bits can cut clean and deep holes in the hardest of woods. Their spiral design draws up (continued on next page) |

||||||||||||||||||||||||||