Woodworker's Journal 1984-8-4, страница 20

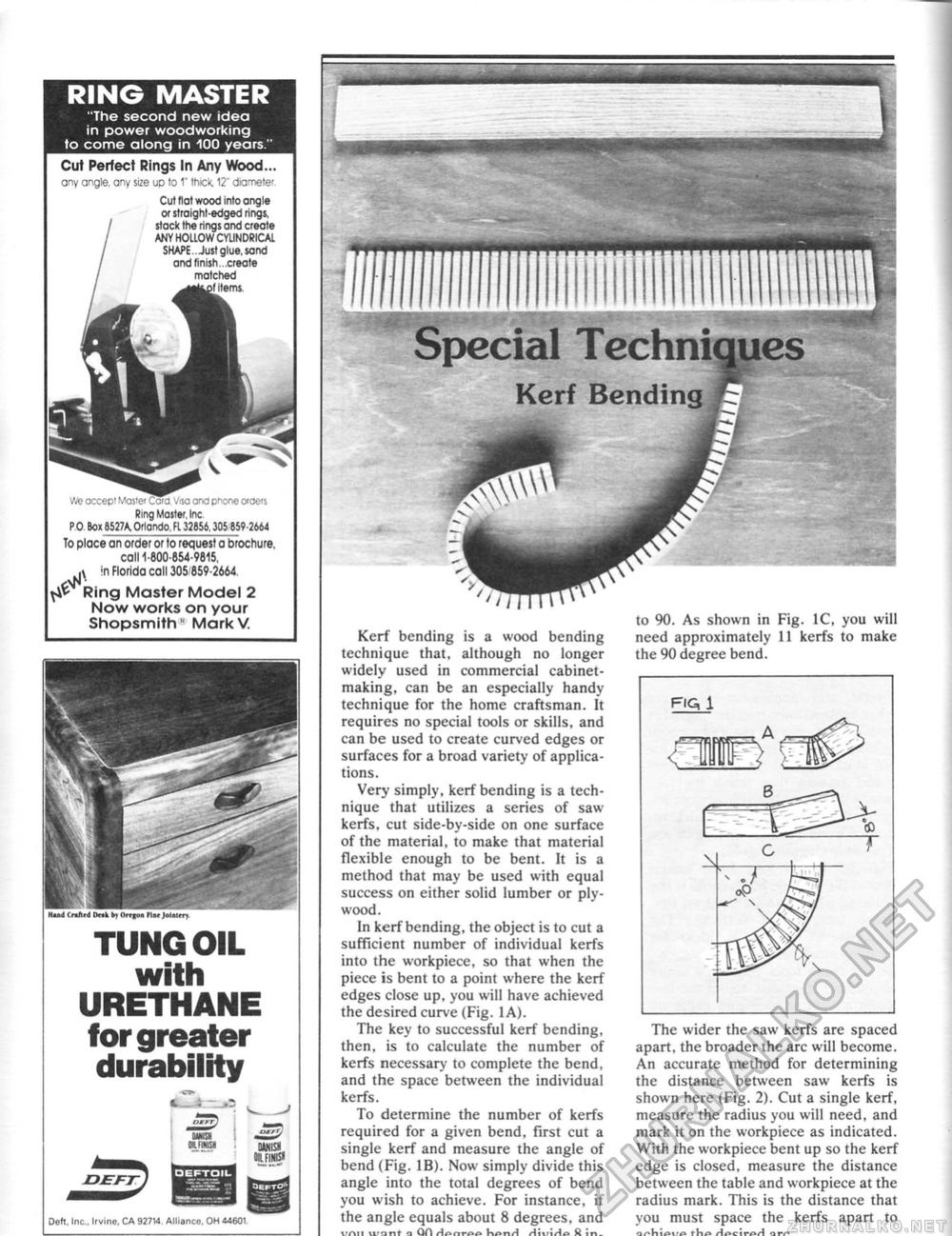

RING MASTER "The second new idea in power woodworking to come along in 100 years." Cut Perfect Rings In Any Wood... any angle, any size up to t thick. 12" diameter Hud Cnflrd bi OrtgoB I La* »l,r> TUNG OIL with URETHANE for greater durability Deft. Inc., Irvine, CA 92714 Alliance, OH 44601 Special Techniques Kerf Bending Kerf bending is a wood bending technique that, although no longer widely used in commercial cabinet-making, can be an especially handy technique for the home craftsman. It requires no special tools or skills, and can be used to create curved edges or surfaces for a broad variety of applications. Very simply, kerf bending is a technique that utilizes a series of saw kerfs, cut side-by-side on one surface of the material, to make that material flexible enough to be bent. It is a method that may be used with equal success on either solid lumber or plywood. In kerf bending, the object is to cut a sufficient number of individual kerfs into the workpiece, so that when the piece is bent to a point where the kerf edges close up, you will have achieved the desired curve (Fig. 1 A). The key to successful kerf bending, then, is to calculate the number of kerfs necessary to complete the bend, and the space between the individual kerfs. To determine the number of kerfs required for a given bend, first cut a single kerf and measure the angle of bend (Fig. IB). Now simply divide this angle into the total degrees of bend you wish to achieve. For instance, if the angle equals about 8 degrees, and uAll u'ant q OH Kati/H i4iuiHf> R in. to 90. As shown in Fig. 1C, you will need approximately 11 kerfs to make the 90 degree bend. The wider the saw kerfs are spaced apart, the broader the arc will become. An accurate method for determining the distance between saw kerfs is shown here (Fig. 2). Cut a single kerf, measure the radius you will need, and mark it on the workpiece as indicated. With the workpiece bent up so the kerf edge is closed, measure the distance between the table and workpiece at the radius mark. This is the distance that you must space the kerfs apart to a/"-liiaiv To ploce anofdei or to request a brochure, coll 1-800-854-9815. !n Florida call 305 859 2664 ^ Ring Master Model 2 Now works on your Shopsmith " MarkV. Cut (lot wood into angle or straight-edged rings, stack the rings and create ANY HOllOW CYLINDRICAL SHAPE... Juslglue. sand and finish...create matched 'We accept Master Cord. Visa ana pnone oraers Ring Master, Inc ? 0 Box 9527A Orlando. Ft 32656.305 659-26M |