Woodworker's Journal 1984-8-5, страница 16

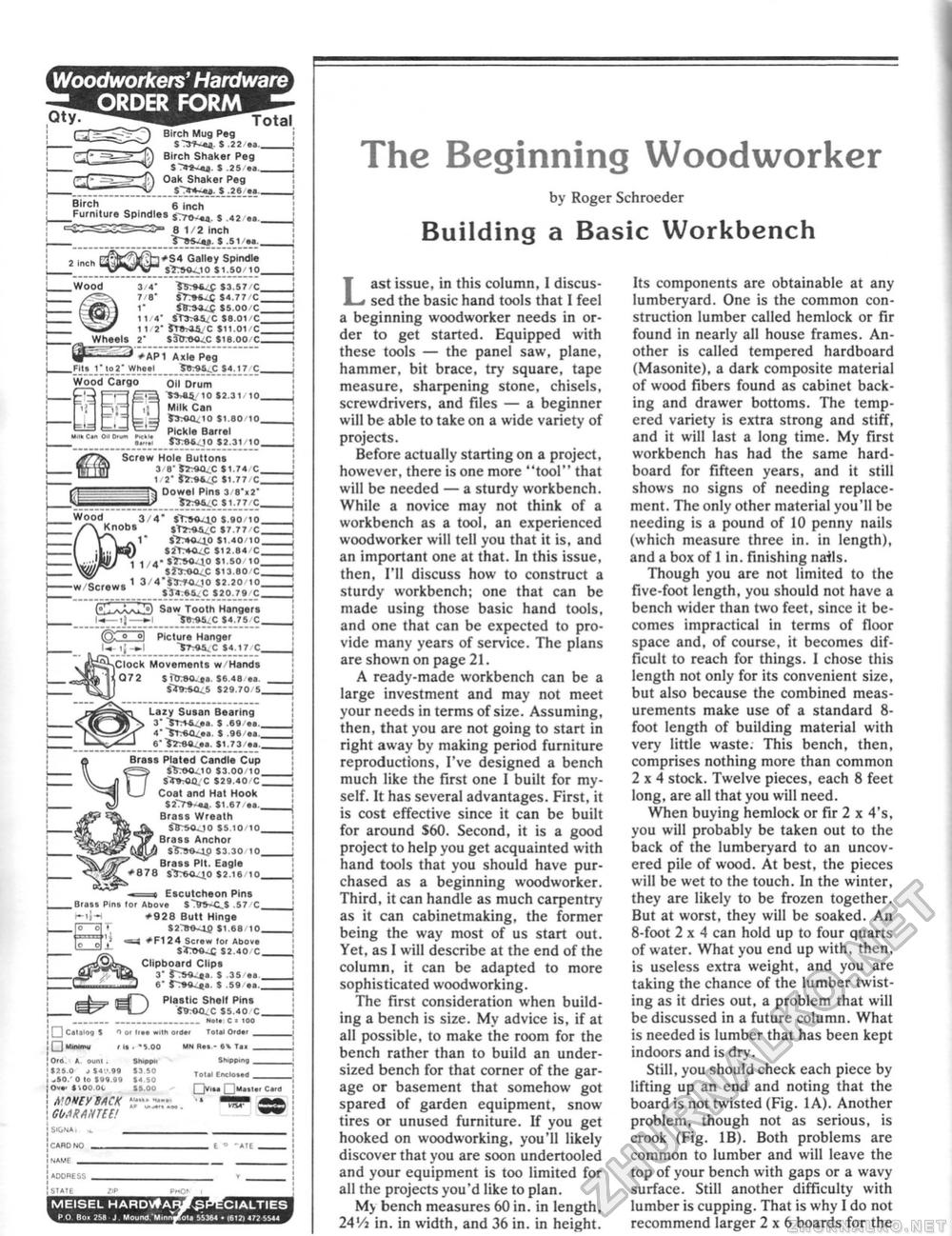

Woodworkers' Hardware ORDER FORM Total Birch Mug Peg $ .22 Birch Shaker Peg S .25 pa _ Oak Shaker Peg iirch. c- ■ " 6Tiic'h"" _Furniture Spindles s?70~m. s .42 8 1/2 inch i .51 M._ »S4 Galley Spindle s'frsooo Si.50 10. _Wood 3 f Tsrssj S3.57/c_ 7/8" S4.77/C, i" SB^JhJ? S5.00/C_ 11 4- sTsr»s.c sa.01 c~ 112' Sy^m, c S11.01 c_ Wheels 2" sJttOO^C S16.OO C. Ir''"1" *AP1 Axle Peg _FU»_1 ____SBtSS. C S4.1_t.C_ Wood Cargo oil Drum ^ "WAS. 10 S2.31/10_ Milk Can .tj Sa^Uio $1 so io_ Pickle Barrel SI.31 10, Screw Hole Buttons 3 6' J1.74 C„ 1/1" »t.7T/C_ Dowel Pins g/a'il' 77 Wood 3/4- $.90/10,. Knobs STM44C S7.77/C. . 1* SY^JO S1 40 10~ J12.84 C_ .■ ■■•MjlJ . , a " sr-se-to si . so io_ sfr^o^c sia.Bo 1 3/4*sWO^lO SI.20 io_ IJMI.C $20.79 C_ EIaaaI3 Saw Tooth Hangers U—_1_| SBM..CS4 75 C, Picture Hanger "IT?«S.C S4 17 c_ -,C1ock Movements w Hands 072 S iO.BO. ja $6 48 on SJ9.70 5_ Lazy Susan Bearing 3" "iT-ti^M. $ 6B ««._ 4' $ .98 $1.71 _ Brass Plated Candle Cup S3.00 10 S^rOO, C S24 40 C. Coat and Hat Hook SI>S~«*. si.67.•a._ Brass Wreath £B~5<LJ0 S5.10/10_ Brass Anchor sTss-op $3.30 io_ Brass Pit. Eagle *87B sT^ttjo $2.16 10_ Escutcheon Pins _ Brass Ptn» for Above .87 t—ij-H *92B Butt Hinge SITSS-JJ) $1.68 10_ <oM * F1 2 4 Screw lor Above s^roej; si.40 c_ Clipboard Clips 3" S .35 88 _ 8" f^ea^a. $ .58 »>._ Plastic Shelf Pins S9.oa._c $5 40 _________„_____Nol* C * 10a r* or '<•« with Old** TO til O'dn _ I [3 Catalog 1 | Q M,nln»u * I j Orel A Bunt . IS35.0 J .SO.' 0 10 109.93 ; OV*. S iOO QL mVEYBACK £ \ GUARANTEE! I Hat - 6V Tax Shipping . Total Enclosed . The Beginning Woodworker by Roger Schroeder Building a Basic Workbench Last issue, in this column, I discussed the basic hand tools that I feel a beginning woodworker needs in order to get started. Equipped with these tools — the panel saw, plane, hammer, bit brace, try square, tape measure, sharpening stone, chisels, screwdrivers, and files — a beginner will be able to take on a wide variety of projects. Before actually starting on a project, however, there is one more "tool" that will be needed — a sturdy workbench. While a novice may not think of a workbench as a tool, an experienced woodworker will tell you that it is, and an important one at that. In this issue, then, I'll discuss how to construct a sturdy workbench; one that can be made using those basic hand tools, and one that can be expected to provide many years of service. The plans are shown on page 21. A ready-made workbench can be a large investment and may not meet your needs in terms of size. Assuming, then, that you are not going to start in right away by making period furniture reproductions, I've designed a bench much like the first one 1 built for myself. It has several advantages. First, it is cost effective since it can be built for around $60. Second, it is a good project to help you get acquainted with hand tools that you should have purchased as a beginning woodworker. Third, it can handle as much carpentry as it can cabinetmaking, the former being the way most of us start out. Yet, as I will describe at the end of the column, it can be adapted to more sophisticated woodworking. The first consideration when building a bench is size. My advice is, if at all possible, to make the room for the bench rather than to build an undersized bench for that corner of the garage or basement that somehow got spared of garden equipment, snow tires or unused furniture. If you get hooked on woodworking, you'll likely discover that you are soon undertooled and your equipment is too limited for all the projects you'd like to plan. M> bench measures 60 in. in length, 24Vi in, in width, and 36 in. in height. Its components are obtainable at any lumberyard. One is the common construction lumber called hemlock or fir found in nearly all house frames. Another is called tempered hardboard (Masonite), a dark composite material of wood fibers found as cabinet backing and drawer bottoms. The tempered variety is extra strong and stiff, and it will last a long time. My first workbench has had the same hard-board for fifteen years, and it still shows no signs of needing replacement. The only other material you'll be needing is a pound of 10 penny nails (which measure three in. in length), and a box of 1 in. finishing nails. Though you are not limited to the five-foot length, you should not have a bench wider than two feet, since it becomes impractical in terms of floor space and, of course, it becomes difficult to reach for things. 1 chose this length not only for its convenient size, but also because the combined measurements make use of a standard 8-foot length of building material with very little waste. This bench, then, comprises nothing more than common 2x4 stock. Twelve pieces, each 8 feet long, are all that you will need. When buying hemlock or fir 2 x 4's, you will probably be taken out to the back of the lumberyard to an uncovered pile of wood. At best, the pieces will be wet to the touch. In the winter, they are likely to be frozen together. But at worst, they will be soaked. An 8-foot 2x4 can hold up to four quarts of water. What you end up with, then, is useless extra weight, and you are taking the chance of the lumber twisting as it dries out, a problem that will be discussed in a future column. What is needed is lumber that has been kept indoors and is dry. Still, you should check each piece by lifting up an end and noting that the board is not twisted (Fig. 1 A). Another problem, though not as serious, is crook (Fig. IB). Both problems are common to lumber and will leave the top of your bench with gaps or a wavy surface. Still another difficulty with lumber is cupping. That is why I do not recommend larger 2x6 boards for the |