Woodworker's Journal 1984-8-5, страница 34

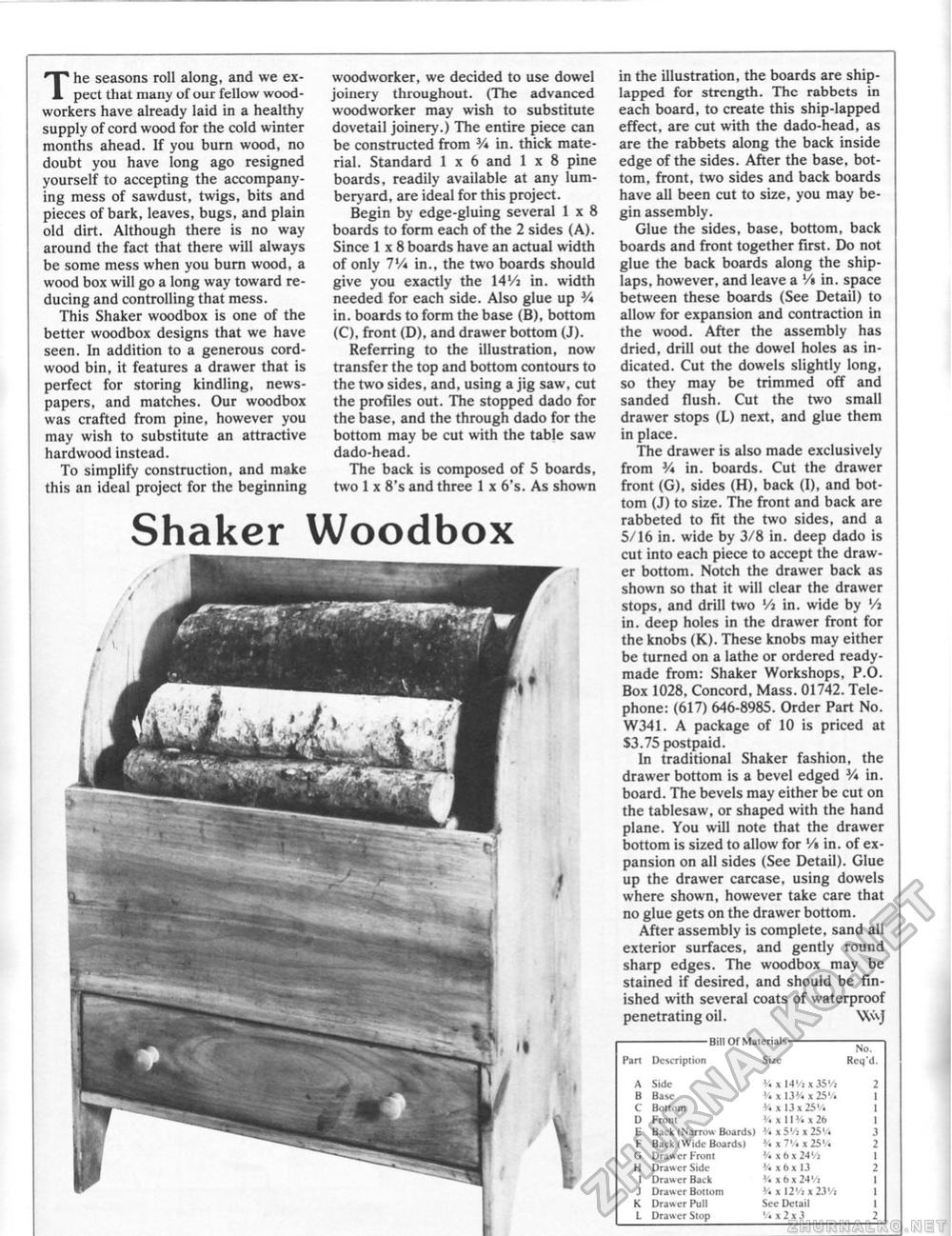

The seasons roll along, and we expect that many of our fellow woodworkers have already laid in a healthy supply of cord wood for the cold winter months ahead, If you burn wood, no doubt you have long ago resigned yourself to accepting the accompanying mess of sawdust, twigs, bits and pieces of bark, leaves, bugs, and plain old dirt. Although there is no way around the fact that there will always be some mess when you burn wood, a wood box will go a long way toward reducing and controlling that mess. This Shaker woodbox is one of the better woodbox designs that we have seen. In addition to a generous cord-wood bin, it features a drawer that is perfect for storing kindling, newspapers, and matches. Our woodbox was crafted from pine, however you may wish to substitute an attractive hardwood instead. To simplify construction, and make this an ideal project for the beginning woodworker, we decided to use dowel joinery throughout, (The advanced woodworker may wish to substitute dovetail joinery.) The entire piece can be constructed from V* in. thick material. Standard 1x6 and 1 x 8 pine boards, readily available at any lumberyard, are ideal for this project. Begin by edge-gluing several 1x8 boards to form each of the 2 sides (A). Since 1x8 boards have an actual width of only 7Vi in., the two boards should give you exactly the 14'/a in. width needed for each side. Also glue up V* in. boards to form the base (B), bottom (C), front (D), and drawer bottom (J). Referring to the illustration, now transfer the top and bottom contours to the two sides, and, using a jig saw, cut the profiles out. The stopped dado for the base, and the through dado for the bottom may be cut with the table saw dado-head. The back is composed of 5 boards, two 1 x 8's and three 1 x 6's. As shown in the illustration, the boards are ship-lapped for strength. The rabbets in each board, to create this ship-lapped effect, are cut with the dado-head, as are the rabbets along the back inside edge of the sides. After the base, bottom, front, two sides and back boards have all been cut to size, you may begin assembly. Glue the sides, base, bottom, back boards and front together first. Do not glue the back boards along the ship-laps, however, and leave a '/« in, space between these boards (See Detail) to allow for expansion and contraction in the wood. After the assembly has dried, drill out the dowel holes as indicated. Cut the dowels slightly long, so they may be trimmed off and sanded flush. Cut the two small drawer stops (L) next, and glue them in place. The drawer is also made exclusively from V• in. boards. Cut the drawer front (G), sides (H), back (I), and bottom (J) to size. The front and back are rabbeted to fit the two sides, and a 5/16 in. wide by 3/8 in. deep dado is cut into each piece to accept the drawer bottom. Notch the drawer back as shown so that it will clear the drawer stops, and drill two Vi in. wide by '/a in. deep holes in the drawer front for the knobs (K). These knobs may either be turned on a lathe or ordered ready-made from: Shaker Workshops, P.O. Box 1028, Concord, Mass. 01742. Telephone: (617) 646-8985. Order Part No. W341. A package of 10 is priced at S3.75 postpaid. In traditional Shaker fashion, the drawer bottom is a bevel edged V* in. board. The bevels may either be cut on the tablesaw, or shaped with the hand plane. You will note that the drawer bottom is sized to allow for '/»in. of expansion on ail sides (See Detail). Glue up the drawer carcase, using dowels where shown, however take care that no glue gets on the drawer bottom. After assembly is complete, sand all exterior surfaces, and gently round sharp edges. The woodbox may be stained if desired, and should be finished with several coats of waterproof penetrating oil. Wvj Bill Of Materials--— No. Bill Of Materials--— No.

|