Woodworker's Journal 1984-8-5, страница 42

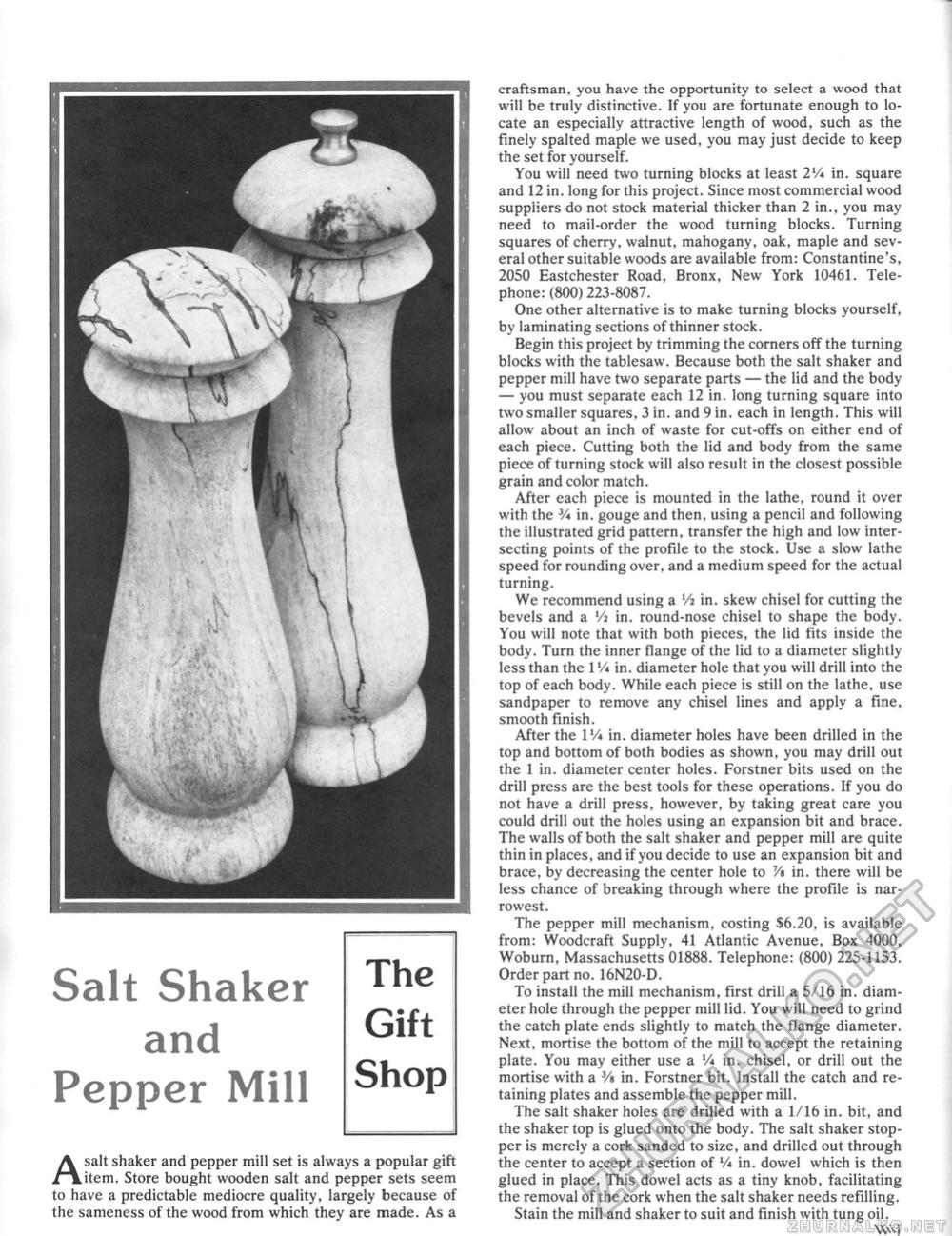

Salt Shaker and Pepper Mill A salt shaker and pepper mill set is always a popular gift item. Store bought wooden salt and pepper sets seem to have a predictable mediocre quality, largely because of the sameness of the wood from which they are made. As a craftsman, you have the opportunity to select a wood that will be truly distinctive. If you are fortunate enough to locate an especially attractive length of wood, such as the finely spalted maple we used, you may just decide to keep the set for yourself. You will need two turning blocks at least 2% in. square and 12 in. long for this project. Since most commercial wood suppliers do not stock material thicker than 2 in., you may need to mail-order the wood turning blocks. Turning squares of cherry, walnut, mahogany, oak, maple and several other suitable woods are available from: Constantine's, 2050 Eastchester Road, Bronx, New York 10461. Telephone: (800) 223-8087. One other alternative is to make turning blocks yourself, by laminating sections of thinner stock. Begin this project by trimming the corners off the turning blocks with the tablesaw. Because both the salt shaker and pepper mill have two separate parts — the lid and the body — you must separate each 12 in. long turning square into two smaller squares, 3 in. and 9 in. each in length. This will allow about an inch of waste for cut-offs on either end of each piece. Cutting both the lid and body from the same piece of turning stock will also result in the closest possible grain and color match. After each piece is mounted in the lathe, round it over with the V* in. gouge and then, using a pencil and following the illustrated grid pattern, transfer the high and low intersecting points of the profile to the stock. Use a slow lathe speed for rounding over, and a medium speed for the actual turning. We recommend using a '/a in. skew chisel for cutting the bevels and a Vi in. round-nose chisel to shape the body. You will note that with both pieces, the lid fits inside the body. Turn the inner flange of the lid to a diameter slightly less than the VA in. diameter hole that you will drill into the top of each body. While each piece is still on the lathe, use sandpaper to remove any chisel lines and apply a fine, smooth finish. After the 1V* in. diameter holes have been drilled in the top and bottom of both bodies as shown, you may drill out the 1 in. diameter center holes. Forstner bits used on the drill press are the best tools for these operations. If you do not have a drill press, however, by taking great care you could drill out the holes using an expansion bit and brace. The walls of both the salt shaker and pepper mill are quite thin in places, and if you decide to use an expansion bit and brace, by decreasing the center hole to V» in. there will be less chance of breaking through where the profile is narrowest. The pepper mill mechanism, costing $6.20, is available from: Woodcraft Supply, 41 Atlantic Avenue, Box 4000, Woburn, Massachusetts 01888. Telephone: (800) 225-1153. Order part no. 16N20-D. To install the mill mechanism, first drill a 5/16 in. diameter hole through the pepper mill lid. You will need to grind the catch plate ends slightly to match the flange diameter. Next, mortise the bottom of the mill to accept the retaining plate. You may either use a V* in. chisel, or drill out the mortise with a J/» in. Forstner bit. Install the catch and retaining plates and assemble the pepper mill. The salt shaker holes are drilled with a 1/16 in. bit, and the shaker top is glued onto the body. The salt shaker stopper is merely a cork sanded to size, and drilled out through the center to accept a section of V* in. dowel which is then glued in place. This dowel acts as a tiny knob, facilitating the removal of the cork when the salt shaker needs refilling. Stain the mill and shaker to suit and finish with tung oil. mi |