Woodworker's Journal 1984-8-5, страница 41

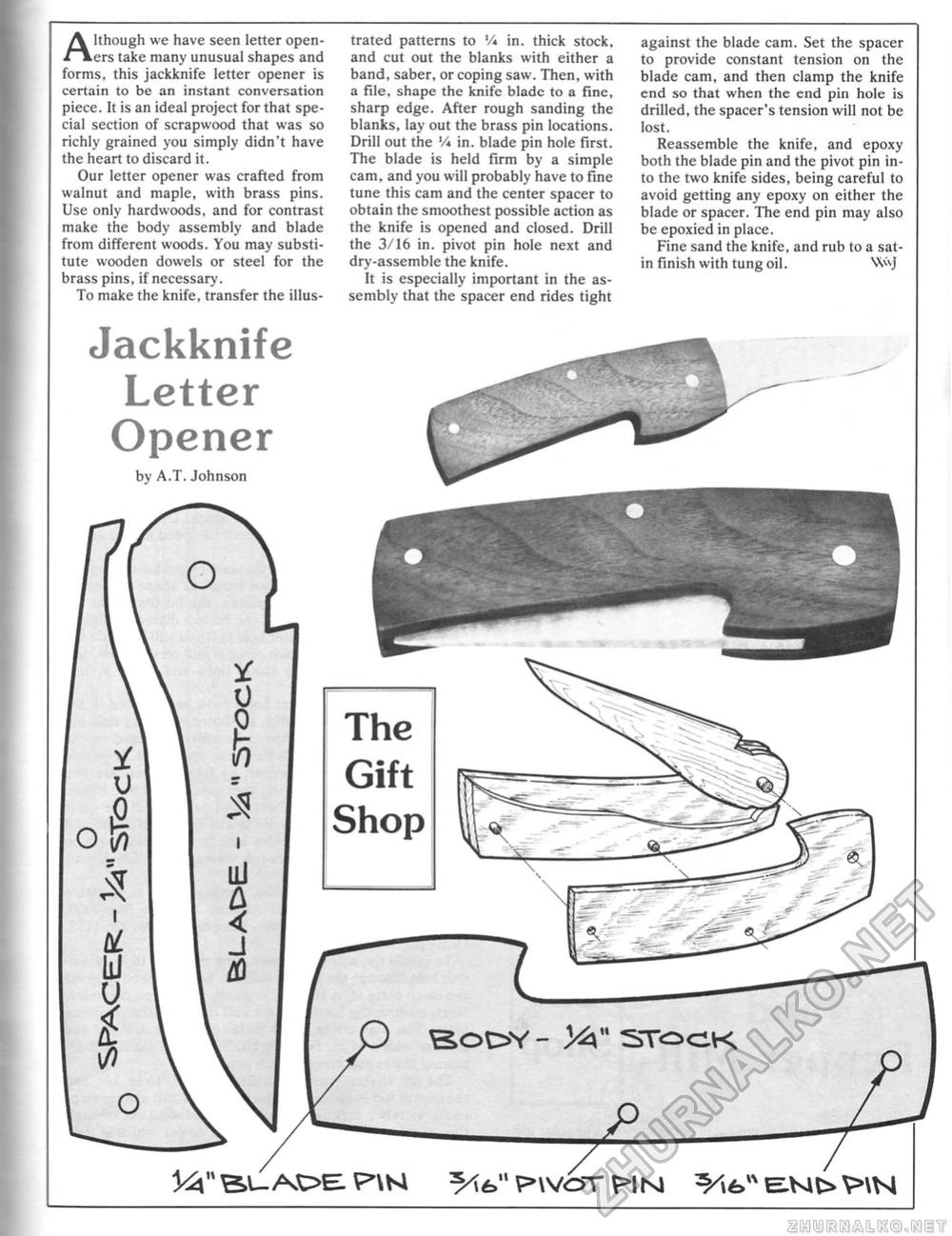

Although we have seen letter openers take many unusual shapes and forms, this jackknife letter opener is certain to be an instant conversation piece. It is an ideal project for that special section of scrapwood that was so richly grained you simply didn't have the heart to discard it. Our letter opener was crafted from walnut and maple, with brass pins. Use only hardwoods, and for contrast make the body assembly and blade from different woods. You may substitute wooden dowels or steel for the brass pins, if necessary. To make the knife, transfer the illus- Jackknife Letter Opener by A.T. Johnson trated patterns to V* in. thick stock, and cut out the blanks with either a band, saber, or coping saw. Then, with a file, shape the knife blade to a Fine, sharp edge. After rough sanding the blanks, lay out the brass pin locations. Drili out the V* in. blade pin hole first. The blade is held firm by a simple cam, and you will probably have to fine tune this cam and the center spacer to obtain the smoothest possible action as the knife is opened and closed. Drill the 3/16 in. pivot pin hole next and dry-assemble the knife. It is especially important in the assembly that the spacer end rides tight against the blade cam. Set the spacer to provide constant tension on the blade cam, and then clamp the knife end so that when the end pin hole is drilled, the spacer's tension will not be lost. Reassemble the knife, and epoxy both the blade pin and the pivot pin into the two knife sides, being careful to avoid getting any epoxy on either the blade or spacer. The end pin may also be epoxied in place. Fine sand the knife, and rub to a sat in finish with tung oil. WvJ |