Woodworker's Journal 1984-8-6, страница 35

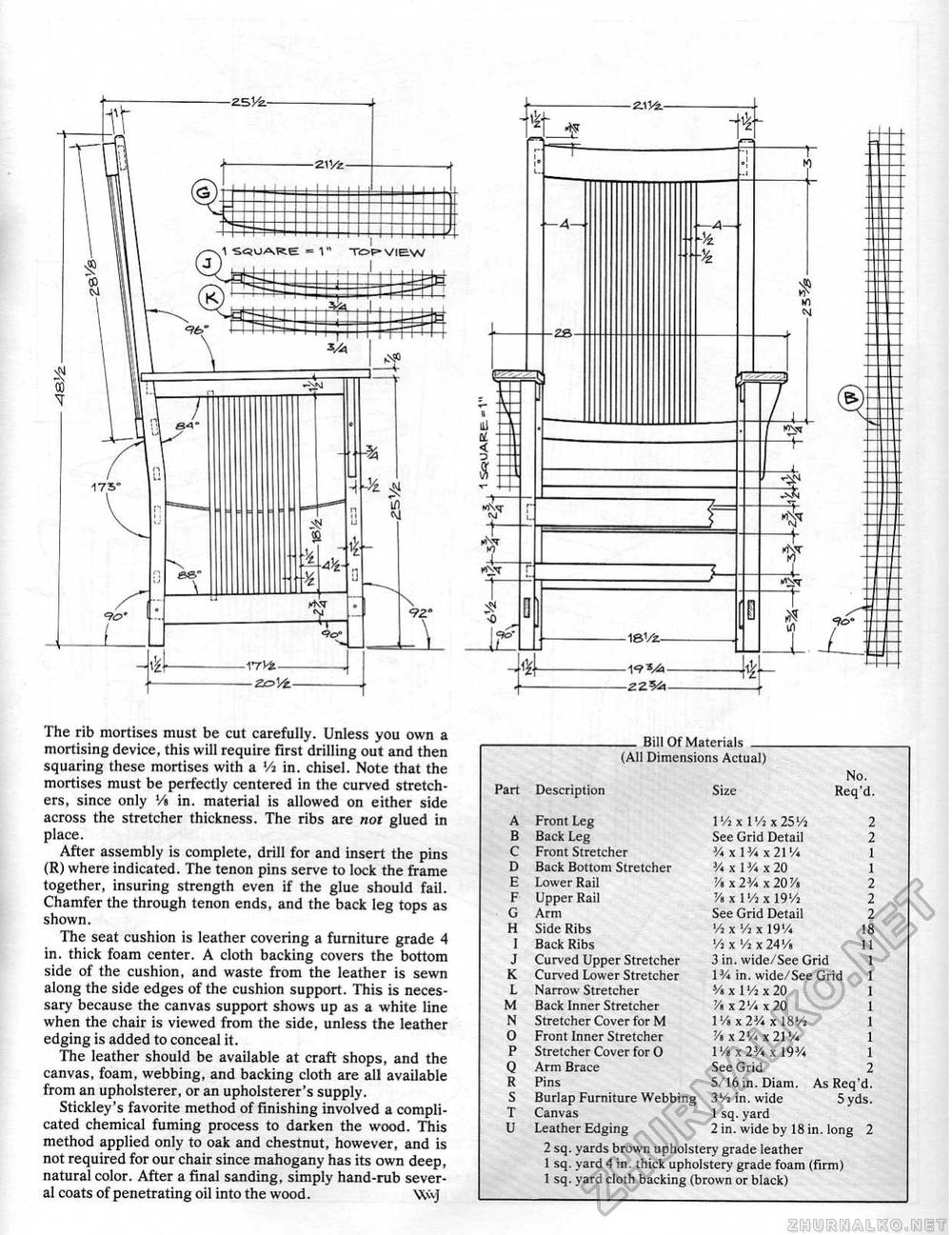

The rib mortises must be cut carefully. Unless you own a mortising device, this will require first drilling out and then squaring these mortises with a Vi in. chisel. Note that the mortises must be perfectly centered in the curved stretchers, since only Vt in. material is allowed on either side across the stretcher thickness. The ribs are not glued in place. After assembly is complete, drill for and insert the pins (R) where indicated. The tenon pins serve to lock the frame together, insuring strength even if the glue should fail. Chamfer the through tenon ends, and the back leg tops as shown. The seat cushion is leather covering a furniture grade 4 in. thick foam center. A cloth backing covers the bottom side of the cushion, and waste from the leather is sewn along the side edges of the cushion support. This is necessary because the canvas support shows up as a white line when the chair is viewed from the side, unless the leather edging is added to conceal it. The leather should be available at craft shops, and the canvas, foam, webbing, and backing cloth are all available from an upholsterer, or an upholsterer's supply. Stickley's favorite method of finishing involved a complicated chemical fuming process to darken the wood. This method applied only to oak and chestnut, however, and is not required for our chair since mahogany has its own deep, natural color. After a final sanding, simply hand-rub several coats of penetrating oil into the wood. W\] _ Bill Of Materials _ (All Dimensions Actual) No. No.

2 sq. yards brown uphoistery grade leather 1 sq. yard 4 in. thick upholstery grade foam (firm) 1 sq. yard cloth backing (brown or black) 2 sq. yards brown uphoistery grade leather 1 sq. yard 4 in. thick upholstery grade foam (firm) 1 sq. yard cloth backing (brown or black) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||