Woodworker's Journal 1984-8-6, страница 37

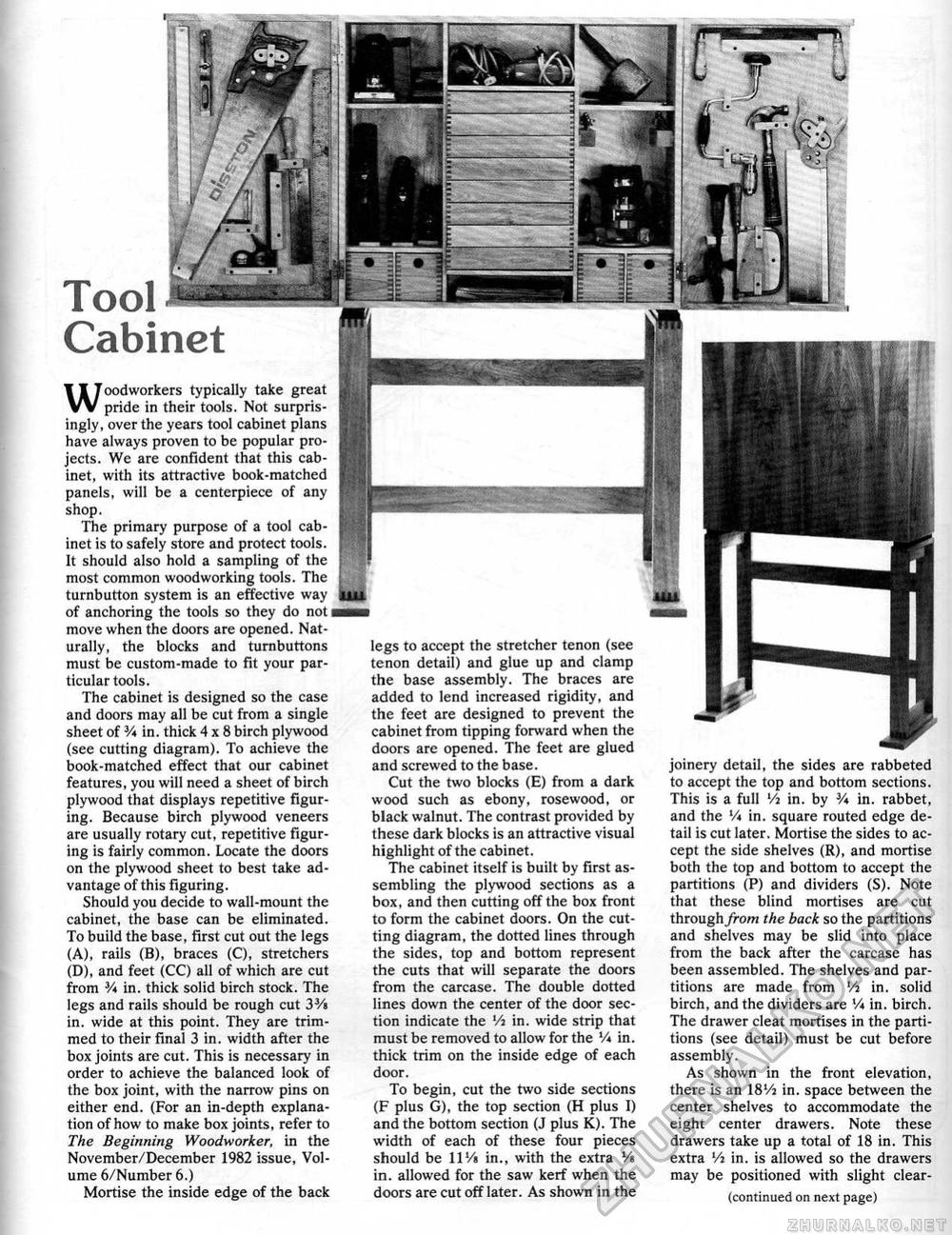

Tool Cabinet Woodworkers typically take great pride in their tools. Not surprisingly, over the years tool cabinet plans have always proven to be popular projects. We are confident that this cabinet, with its attractive book-matched panels, will be a centerpiece of any shop. The primary purpose of a tool cabinet is to safely store and protect tools. It should also hold a sampling of the most common woodworking tools. The turnbutton system is an effective way of anchoring the tools so they do not i move when the doors are opened. Naturally, the blocks and turnbuttons must be custom-made to fit your particular tools. The cabinet is designed so the case and doors may all be cut from a single sheet of V* in. thick 4x8 birch plywood (see cutting diagram). To achieve the book-matched effect that our cabinet features, you will need a sheet of birch plywood that displays repetitive figuring. Because birch plywood veneers are usually rotary cut, repetitive figuring is fairly common. Locate the doors on the plywood sheet to best take advantage of this figuring. Should you decide to wall-mount the cabinet, the base can be eliminated. To build the base, first cut out the legs (A), rails (B), braces (C), stretchers (D), and feet (CC) all of which are cut from Y* in. thick solid birch stock. The legs and rails should be rough cut 33/» in. wide at this point. They are trimmed to their final 3 in. width after the box joints are cut. This is necessary in order to achieve the balanced look of the box joint, with the narrow pins on either end. (For an in-depth explanation of how to make box joints, refer to The Beginning Woodworker, in the November/December 1982 issue, Volume 6/Number 6.) Mortise the inside edge of the back legs to accept the stretcher tenon (see tenon detail) and glue up and clamp the base assembly. The braces are added to tend increased rigidity, and the feet are designed to prevent the cabinet from tipping forward when the doors are opened. The feet are glued and screwed to the base. Cut the two blocks (E) from a dark wood such as ebony, rosewood, or black walnut. The contrast provided by these dark blocks is an attractive visual highlight of the cabinet. The cabinet itself is built by first assembling the plywood sections as a box, and then cutting off the box front to form the cabinet doors. On the cutting diagram, the dotted tines through the sides, top and bottom represent the cuts that wilt separate the doors from the carcase. The double dotted lines down the center of the door section indicate the '/a in. wide strip that must be removed to allow for the '/«in. thick trim on the inside edge of each door. To begin, cut the two side sections (F plus G), the top section (H plus I) and the bottom section (J plus K). The width of each of these four pieces should be ll1/* in., with the extra Va in. allowed for the saw kerf when the doors are cut off later. As shown in the joinery detail, the sides are rabbeted to accept the top and bottom sections. This is a full Vi in. by V* in. rabbet, and the V* in. square routed edge detail is cut later. Mortise the sides to accept the side shelves (R), and mortise both the top and bottom to accept the partitions (P) and dividers (S). Note that these blind mortises are cut through from the back so the partitions and shelves may be slid into place from the back after the carcase has been assembled. The shelves and partitions are made from Vi in. solid birch, and the dividers are Va in. birch. The drawer cleat mortises in the partitions (see detail) must be cut before assembly. As shown in the front elevation, there is an l&Vi in. space between the center shelves to accommodate the eight center drawers. Note these drawers take up a total of 18 in. This extra Vi in. is allowed so the drawers may be positioned with slight clear-(continued on next page} |