Woodworker's Journal 1984-8-6, страница 39

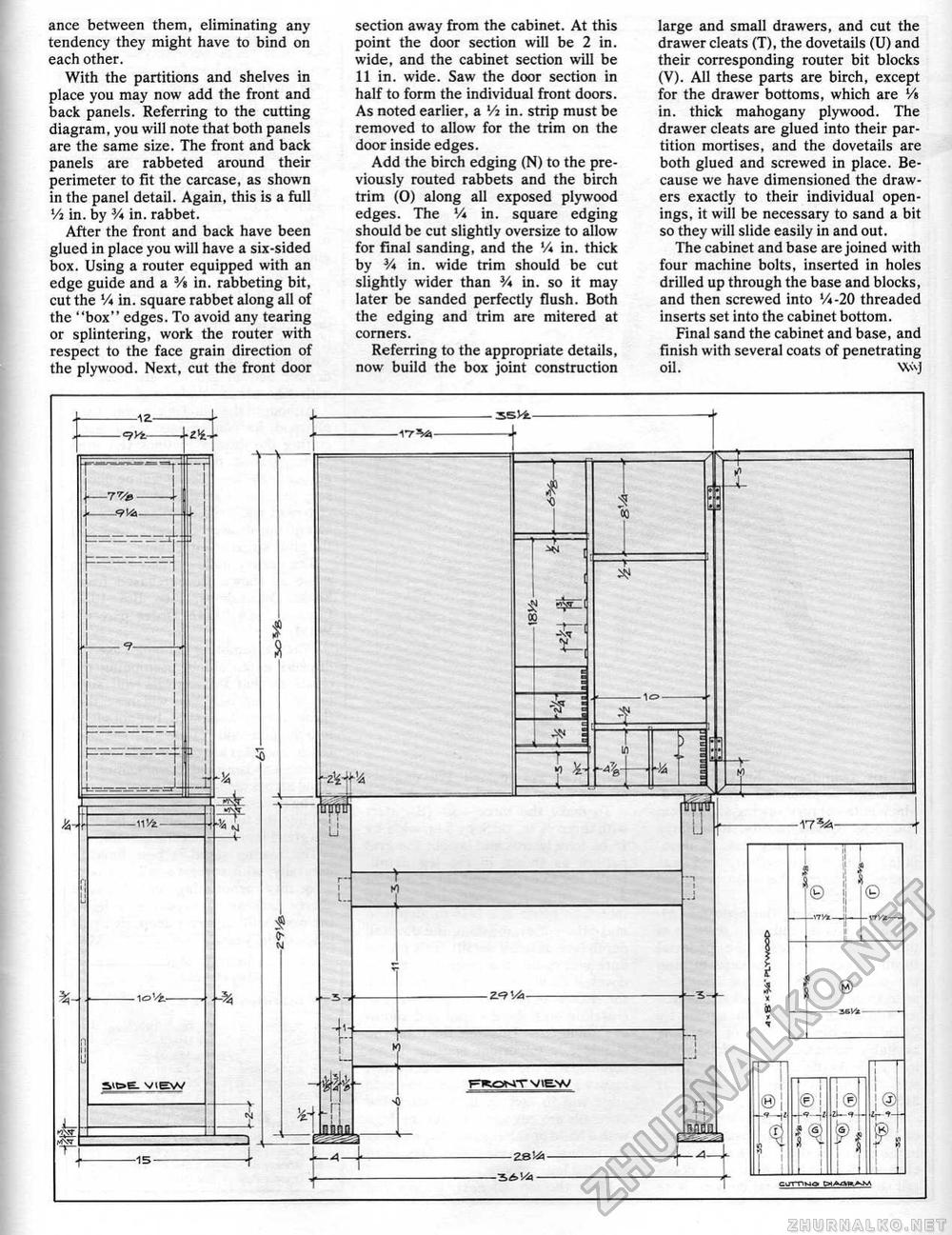

ance between them, eliminating any tendency they might have to bind on each other. With the partitions and shelves in place you may now add the front and back panels. Referring to the cutting diagram, you will note that both panels are the same size. The front and back panels are rabbeted around their perimeter to fit the carcase, as shown in the panel detail. Again, this is a full Vi in. by 3A in. rabbet. After the front and back have been glued in place you will have a six-sided box. Using a router equipped with an edge guide and a V> in. rabbeting bit, cut the V* in. square rabbet along all of the "box" edges. To avoid any tearing or splintering, work the router with respect to the face grain direction of the plywood. Next, cut the front door section away from the cabinet. At this point the door section will be 2 in. wide, and the cabinet section will be 11 in. wide. Saw the door section in half to form the individual front doors. As noted earlier, a Vi in. strip must be removed to allow for the trim on the door inside edges. Add the birch edging (N) to the previously routed rabbets and the birch trim (0) along all exposed plywood edges. The Vi in. square edging should be cut slightly oversize to allow for final sanding, and the V* in. thick by V* in. wide trim should be cut slightly wider than 3A in. so it may later be sanded perfectly flush. Both the edging and trim are mitered at corners. Referring to the appropriate details, now build the box joint construction large and small drawers, and cut the drawer cleats (T), the dovetails (U) and their corresponding router bit blocks (V). All these parts are birch, except for the drawer bottoms, which are l/s in. thick mahogany plywood. The drawer cleats are glued into their partition mortises, and the dovetails are both glued and screwed in place. Because we have dimensioned the drawers exactly to their individual openings, it will be necessary to sand a bit so they will slide easily in and out. The cabinet and base are joined with four machine bolts, inserted in holes drilled up through the base and blocks, and then screwed into Vi-20 threaded inserts set into the cabinet bottom. Final sand the cabinet and base, and finish with several coats of penetrating oil. Wv| |