Woodworker's Journal 1985-9-1, страница 16

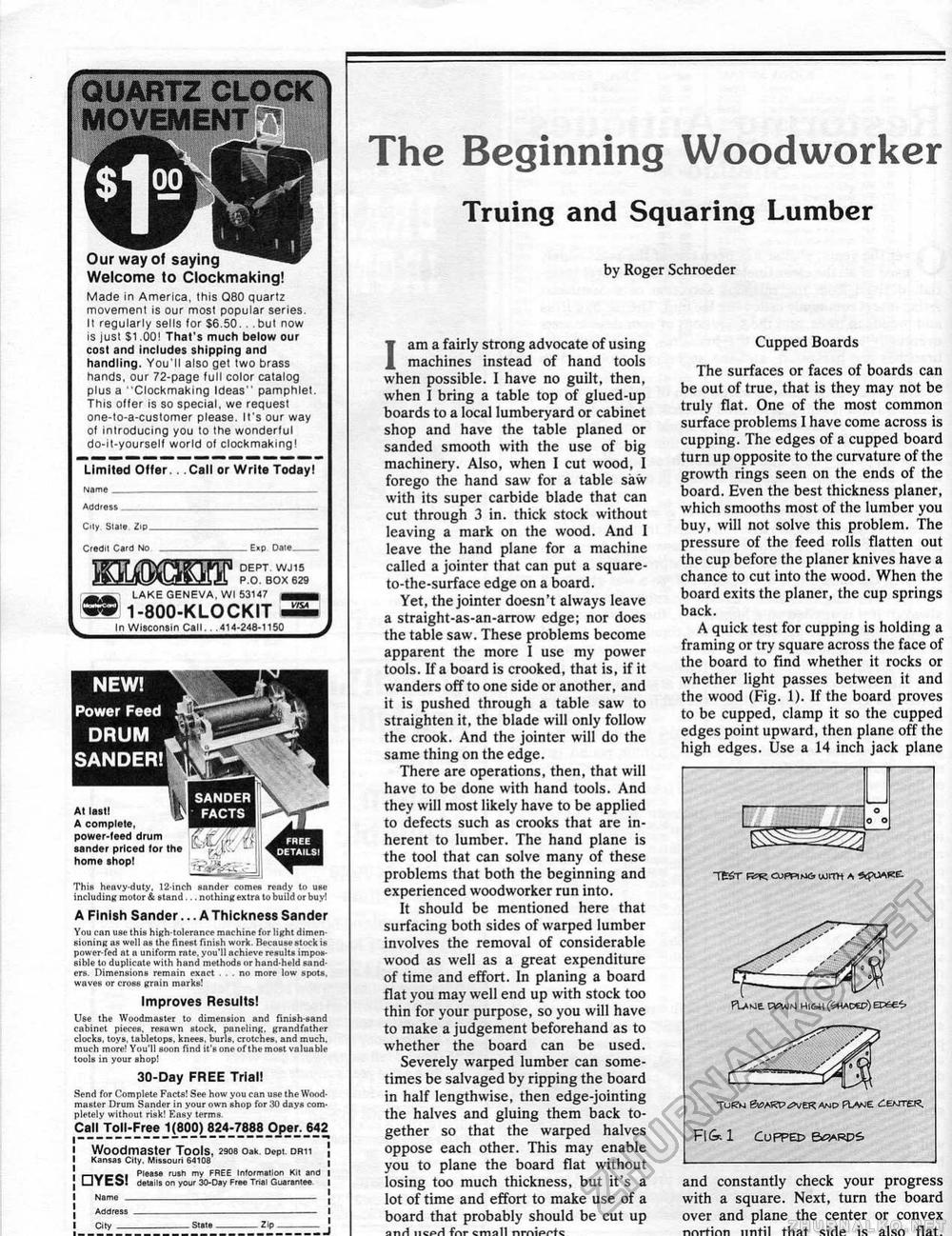

Our way of saying Welcome to Clockmaking! Made in America, (his 080 quartz movement is our most popular series. I! regularly sells for S6.50. . .but now is just $1.00! That's much below our cost and includes shipping and handling. You'll also get two brass hands, our 72-page full color catalog plus a '"Clockmaking Ideas" pamphlet. This oiler is so special, we request one-to-a-customer please. It's our way of Introducing you to the wonderful do-il-yourself world of clockmaking! Limited Offer. . Call or Write Today! Name _„_ Address (My. Slug Zip- Credn Card No _ . E»p Oaie IMOT DEPT WJ15 P.O. BOX 629 __ LAKE GENEVA, Wl 53147 mmm 5® I-8OO-KLOCKIT — V In Wi scoria in Call.. 4-2dB-l 150 NEW! Power Feed DRUM SANDER! At lost! A complete, power-feed drum sander priced lor the home shopt Thin heavy-duty. 12-inch sander comes ready to use including motor & stand ... nothing extra to build or buy! A Finish Sander... AThickness Sander You can use this high-tolerance machine for light dimensioning as well as the finest finish work. Because stock is power-fed at a uniform rate, you'll achieve results impossible to duplicate with hand methods or hand-held ganders. Dimensions remain exact ... no more low spots, waves or cross grain marks! Improves Results! Use the Woodmaster to dimension and finish-sand cabinet pieces, resawn stock, paneling, grandfather clocks, toys, tabletopB, knees, burls, crotches, and much, much more! You'll soon find it's one of the most valuable tools in your shop! 30-Day FREE Trial! Send for Complete Facts! See how you can use the Wood-master Drum Sander in your own shop for 30 days completely without risk! Easy terms. Call Toll-Free 1(800) 824-7888 Oper 642 Woodmaster Tools, 290B oak Dept. dru Kansas City. Missouri 6410B Please rush my FREE Information Kit and LJ Y t o! details on your 30-Day Free Trial Guarantee Address City - -Z'P - The Beginning Woodworker Truing and Squaring Lumber by Roger Schroeder I am a fairly strong advocate of using machines instead of hand tools when possible. 1 have no guilt, then, when I bring a table top of glued-up boards to a local lumberyard or cabinet shop and have the table planed or sanded smooth with the use of big machinery. Also, when I cut wood, I forego the hand saw for a table saw with its super carbide blade that can cut through 3 in. thick stock without leaving a mark on the wood. And I leave the hand plane for a machine called a jointer that can put a square-to-the-surface edge on a board. Yet, the jointer doesn't always leave a straight-as-an-arrow edge; nor does the table saw. These problems become apparent the more I use my power tools. If a board is crooked, that is, if it wanders off to one side or another, and it is pushed through a table saw to straighten it, the blade will only follow the crook. And the jointer will do the same thing on the edge. There are operations, then, that will have to be done with hand tools. And they will most likely have to be applied to defects such as crooks that are inherent to lumber. The hand plane is the tool that can solve many of these problems that both the beginning and experienced woodworker run into. It should be mentioned here that surfacing both sides of warped lumber involves the removal of considerable wood as well as a great expenditure of time and effort. In planing a board flat you may well end up with stock too thin for your purpose, so you will have to make a judgement beforehand as to whether the board can be used. Severely warped lumber can sometimes be salvaged by ripping the board in half lengthwise, then edge-jointing the halves and gluing them back together so that the warped halves oppose each other. This may enable you to plane the board flat without losing too much thickness, but it's a lot of time and effort to make use of a board that probably should be cut up atiH -for email nrni^rtc Cupped Boards The surfaces or faces of boards can be out of true, that is they may not be truly flat. One of the most common surface problems I have come across is cupping. The edges of a cupped board turn up opposite to the curvature of the growth rings seen on the ends of the board. Even the best thickness planer, which smooths most of the lumber you buy, will not solve this problem. The pressure of the feed rolls flatten out the cup before the planer knives have a chance to cut into the wood. When the board exits the planer, the cup springs back. A quick test for cupping is holding a framing or try square across the face of the board to find whether it rocks or whether light passes between it and the wood (Fig. 1). If the board proves to be cupped, clamp it so the cupped edges point upward, then plane off the high edges. Use a 14 inch jack plane and constantly check your progress with a square. Next, turn the board over and plane the center or convex nrvrtinn until that side is also flat. "TEST RS=R euppiMfir wrm PiJ>JE BVW Hl&H ADEP) TOF?M ewMZv&veK AND FLVJE £&JTER FI& 1 Cupped QpakdS |