Woodworker's Journal 1985-9-1, страница 59

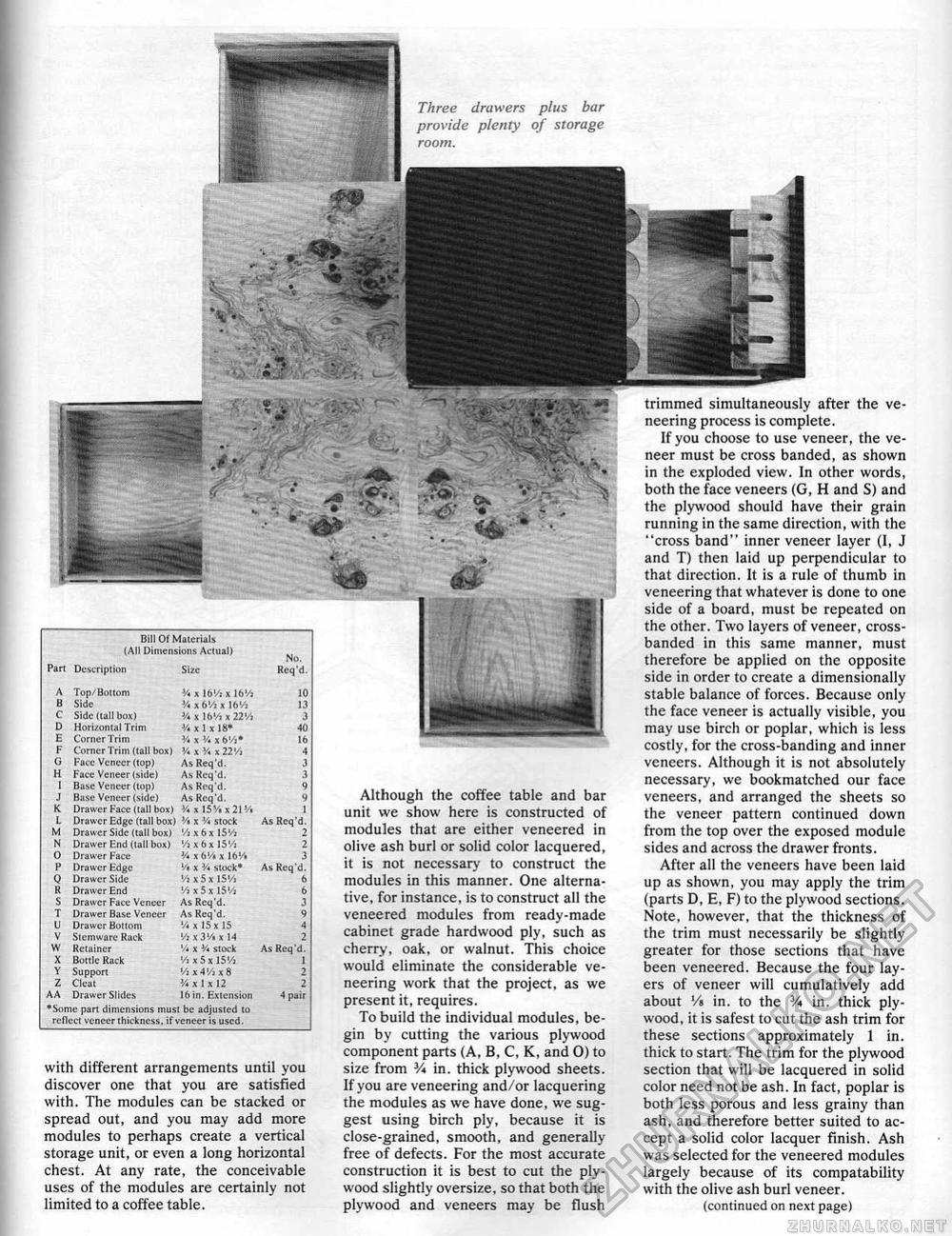

Three drawers plus bar provide plenty of storage a • r • . J. • ■■ * fr ~ - Bill Of Materials Bill Of Materials

* Some pan dimensions must be adjusted to reflect veneer thickness, if veneer is used. * Some pan dimensions must be adjusted to reflect veneer thickness, if veneer is used. with different arrangements until you discover one that you are satisfied with. The modules can be stacked or spread out, and you may add more modules to perhaps create a vertical storage unit, or even a long horizontal chest. At any rate, the conceivable uses of the modules are certainly not limited to a coffee table. Although the coffee table and bar unit we show here is constructed of modules that are either veneered in olive ash burl or solid color lacquered, it is not necessary to construct the modules in this manner. One alternative, for instance, is to construct all the veneered modules from ready-made cabinet grade hardwood piy, such as cherry, oak, or walnut. This choice would eliminate the considerable veneering work that the project, as we present it, requires. To build the individual modules, begin by cutting the various plywood component parts {A, B, C, K, and O) to size from in. thick plywood sheets. If you are veneering and/or lacquering the modules as we have done, we suggest using birch ply, because it is close-grained, smooth, and generally free of defects. For the most accurate construction it is best to cut the plywood slightly oversize, so that both the plywood and veneers may be flush trimmed simultaneously after the veneering process is complete. If you choose to use veneer, the veneer must be cross banded, as shown in the exploded view. In other words, both the face veneers (G, H and S) and the plywood should have their grain running in the same direction, with the "cross band" inner veneer layer (I, J and T) then laid up perpendicular to that direction. It is a rule of thumb in veneering that whatever is done to one side of a board, must be repeated on the other. Two layers of veneer, cross-banded in this same manner, must therefore be applied on the opposite side in order to create a dimensionally stable balance of forces. Because only the face veneer is actually visible, you may use birch or poplar, which is less costly, for the cross-banding and inner veneers. Although it is not absolutely necessary, we bookmatched our face veneers, and arranged the sheets so the veneer pattern continued down from the top over the exposed module sides and across the drawer fronts. After all the veneers have been laid up as shown, you may apply the trim (parts D, E, F) to the plywood sections. Note, however, that the thickness of the trim must necessarily be slightly greater for those sections that have been veneered. Because the four layers of veneer will cumulatively add about Vt in. to the V* in. thick plywood, it is safest to cut the ash trim for these sections approximately 1 in. thick to start. The trim for the plywood section that will be lacquered in solid color need not be ash. In fact, poplar is both less porous and less grainy than ash, and therefore better suited to accept a solid color lacquer finish. Ash was selected for the veneered modules largely because of its compatability with the olive ash burl veneer. (continued on next page) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||