Woodworker's Journal 1985-9-2, страница 25

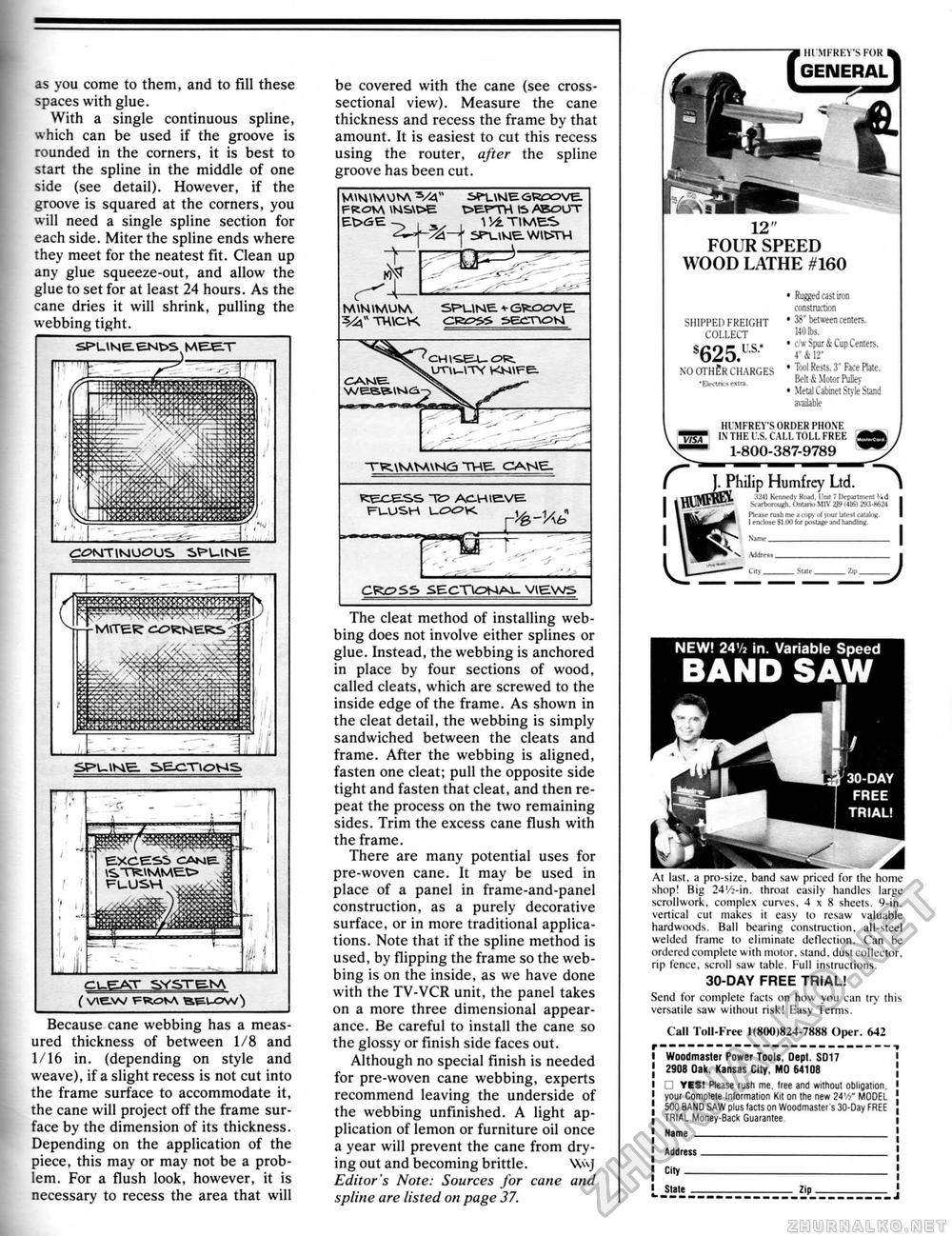

r----------— — —----------- I Woodmaster Power Tools, Dept. SD17 j 2908 Oak, Kansas City. MO 64108 I □ YES! Please rush me. Iree and without obligation. • [ your Complete Information Kit on the new 24W MODEL | J 500 BAND SAW plus facts on Woodmaster s 30-Day FREE [ I TRIAL Money-Back Guarantee ' Name _ [ | Address_ [ > City_ j J_ _Stale ___ Zip_ J be covered with the cane (see cross-sectional view). Measure the cane thickness and recess the frame by that amount. It is easiest to cut this recess using the router, after the spline groove has been cut. The cleat method of installing webbing does not involve either splines or glue. Instead, the webbing is anchored in place by four sections of wood, called cleats, which are screwed to the inside edge of the frame. As shown in the cleat detail, the webbing is simply sandwiched between the cleats and frame. After the webbing is aligned, fasten one cleat; pull the opposite side tight and fasten that cleat, and then repeat the process on the two remaining sides. Trim the excess cane flush with the frame. There are many potential uses for pre-woven cane. It may be used in place of a panel in frame-and-panel construction, as a purely decorative surface, or in more traditional applications. Note that if the spline method is used, by flipping the frame so the webbing is on the inside, as we have done with the TV-VCR unit, the panel takes on a more three dimensional appearance. Be careful to install the cane so the glossy or finish side faces out. Although no special finish is needed for pre-woven cane webbing, experts recommend leaving the underside of the webbing unfinished. A light application of lemon or furniture oil once a year will prevent the cane from drying out and becoming brittle. Wuj Editor's Note: Sources for cane and spline are listed on page 37. CONTINUOUS SF-LIN& SPUING. sections, CUEAT SYSTEM ( V\e.W FROM S51U3W} as you come to them, and to fill these spaces with glue. With a single continuous spline, which can be used if the groove is rounded in the corners, it is best to start the spline in the middle of one side (see detail). However, if the groove is squared at the corners, you will need a single spline section for each side. Miter the spline ends where they meet for the neatest fit. Clean up any glue squeeze-out, and allow the glue to set for at least 24 hours. As the cane dries it will shrink, pulling the webbing tight. Because cane webbing has a measured thickness of between 1/8 and 1/16 in. (depending on style and weave), if a slight recess is not cut into the frame surface to accommodate it, the cane will project off the frame surface by the dimension of its thickness. Depending on the application of the piece, this may or may not be a problem. For a flush look, however, it is necessary to recess the area that will At last, a pro-size, band saw priced for the home shop! Big 24'/2-in. throat easily handles large scrollwork, complex curves, 4x8 sheets. 9-in. vertical cut makes it easy to resaw valuable hardwoods. Ball bearing construction, all-steel welded frame to eliminate deflection. Can be ordered complete with motor, stand, dust collector, rip fence, scroll saw table. Full instructions. 30-DAY FREE TRIAL! Send for complete facts on how you can try this versatile saw without risk! Easy Terms. Call Toll-Free 1(800)824-7888 Oper. 642 -zip__.J 12" FOUR SPEED WOOD LATHE #160 SHIPPED FREIGHT COLLECT S625.LS' NO OTHER CHARGES •Electrics extra d cast iron construction • 38" betireen centers. 140 lbs. • c/w Spur & Cup Centers. 4" & 12" • Tool Rests. 3" Face Plate. Belt & Motor Pulley • Metal Cabinet Style Stand available 7 Department ltd 21914161 293-8624 hease rush me a copy <J your latest catalog. I enclose St .00 for postage and handling. Name_ VA\^\MV)W\ GROOVE. FROM INSAOE \>EPTH ft about Et>6E-. , 1V*. TIMES f spvtuewitrw V I I__I vL I ' MINIMUM SPUNE. v GVsOOV E1 THICK S>gg-TVSSl KEC&SS TO ACHIEVE FLUSH L-OfK CROSS> SECTION A.U views. CHISEUOR. W4IFE T^\KANV\N<3 THE CANE. |