Woodworker's Journal 1985-9-2, страница 23

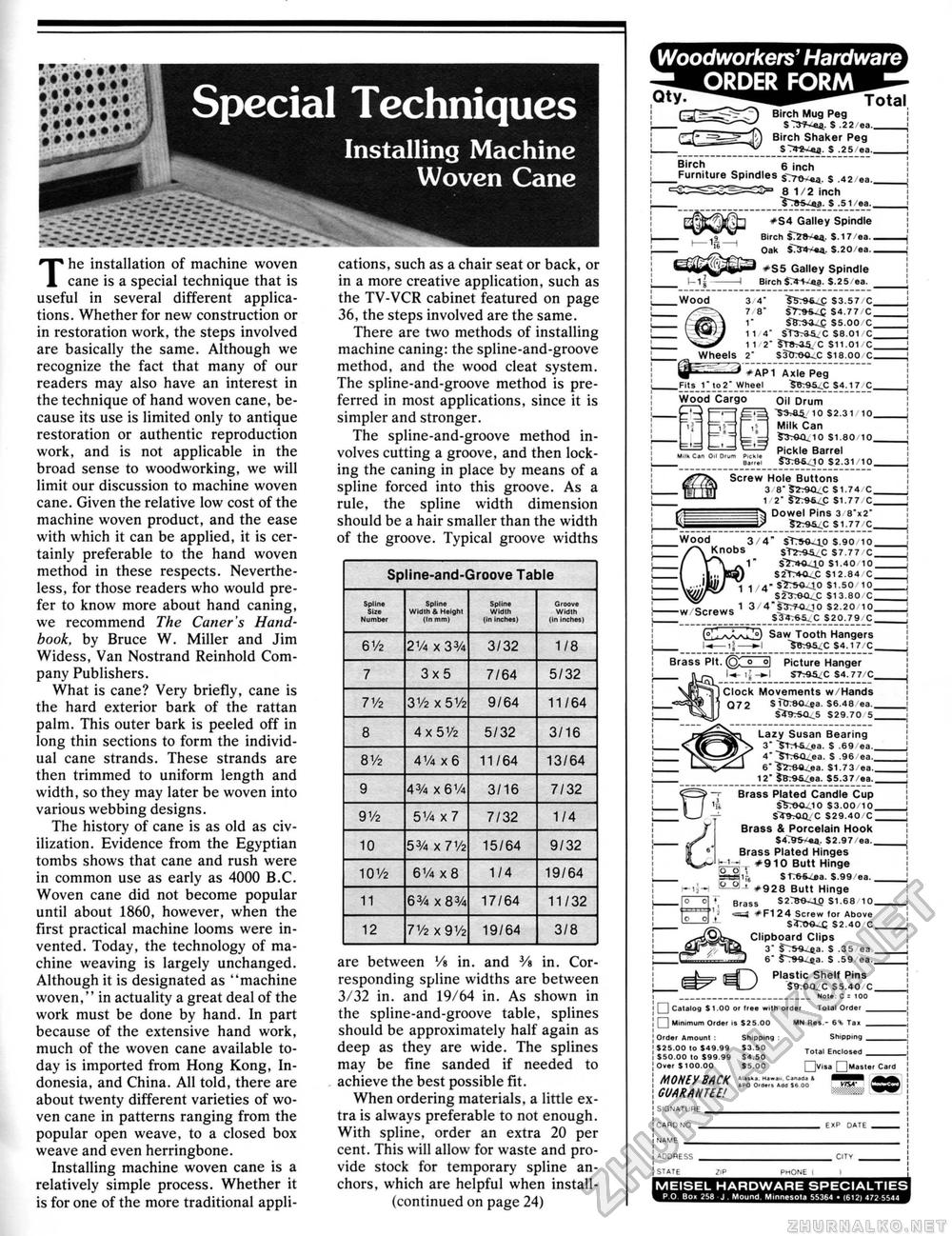

Spccial Techniques Installing Machine Woven Cane The installation of machine woven cane is a special technique that is useful in several different applications. Whether for new construction or in restoration work, the steps involved are basically the same. Although we recognize the fact that many of our readers may also have an interest in the technique of hand woven cane, because its use is limited only to antique restoration or authentic reproduction work, and is not applicable in the broad sense to woodworking, we will limit our discussion to machine woven cane. Given the relative low cost of the machine woven product, and the ease with which it can be applied, it is certainly preferable to the hand woven method in these respects. Nevertheless, for those readers who would prefer to know more about hand caning, we recommend The Carter's Handbook, by Bruce W. Miller and Jim Widess, Van Nostrand Reinhold Company Publishers. What is cane? Very briefly, cane is the hard exterior bark of the rattan palm. This outer bark is peeled off in long thin sections to form the individual cane strands. These strands are then trimmed to uniform length and width, so they may later be woven into various webbing designs. The history of cane is as old as civilization. Evidence from the Egyptian tombs shows that cane and rush were in common use as early as 4000 B.C. Woven cane did not become popular until about 1860, however, when the first practical machine looms were invented. Today, the technology of machine weaving is largely unchanged. Although it is designated as "machine woven," in actuality a great deal of the work must be done by hand. In part because of the extensive hand work, much of the woven cane available today is imported from Hong Kong, Indonesia, and China. All told, there are about twenty different varieties of woven cane in patterns ranging from the popular open weave, to a closed box weave and even herringbone. Installing machine woven cane is a relatively simple process. Whether it is for one of the more traditional appli cations, such as a chair seat or back, or in a more creative application, such as the TV-VCR cabinet featured on page 36, the steps involved are the same. There are two methods of installing machine caning: the spline-and-groove method, and the wood cleat system. The spline-and-groove method is preferred in most applications, since it is simpler and stronger. The spline-and-groove method involves cutting a groove, and then locking the caning in place by means of a spline forced into this groove. As a rule, the spline width dimension should be a hair smaller than the width of the groove. Typical groove widths

are between '/» in. and V» in. Corresponding spline widths are between 3/32 in. and 19/64 in. As shown in the spline-and-groove table, splines should be approximately half again as deep as they are wide. The splines may be fine sanded if needed to achieve the best possible fit. When ordering materials, a little extra is always preferable to not enough. With spline, order an extra 20 per cent. This will allow for waste and provide stock for temporary spline anchors, which are helpful when install-(continued on page 24) Woodworkers' Hardware ORDER FORM ^Qty GE Total Birch Mug Peg STJ^-^a. S .22 ea._ Birch Shaker Peg S .25 ea. _ STirfc^ej. S .25 ea. Birch 6 inch _Furniture Spindles s^ s 42 ea _ 8 1/2 inch S .51 ea.. #S4 Galley Spindle Birch $. 17 'ea. ■ Oak S.20/ea._ #S5 Galley Spindle Birch 5.25 ea. 3 4" S3.57/C_ 7 8" S4.77/C. i" SB^a/j ss.oo.x_ 11 4" S8.01 C~ 1 1 2" ITStAS. C S11.01/C~ Wheels 2" sStrsfeX S18.00 cl lip' * *AP1 Axle Peg .Fits I'm2' Wheel 'SBras^c:S4.17 c_ Wood Cargo 0il Drum .coders -5^,0 S2.31 10. in HHm Milk Can S1.80/10_ Pickle Barrel S2.31/10. Milk Can Oil Drum Prchi* Screw Hole Buttons 3 8"?2^CLC S1.74 c_ 1 2" ?2r96^C S1.77 C_ Dowel Pins 3/8'x2" L' " 5M5..CSI 77 C. Wood 3/4" sTrs«jp s.90 io_ Knobs S7.77 c_ .1" 51.40 io_ S1 2.84 C_ X, 4-S1.50 10_ $13.80 C_ Srrews1 3/4"i*^OJO $2.20 10_ screws S'JS^LC S20.79 c_ Saw Tooth Hangers -I S4.17/C. Brass Pit. Picture Hanger STrft^C S4.77/C. Clock Movements w Hands Q72 S ilrsO^ea. S6.48 ea._ Si^rSQ^S S29.70 5_ Lazy Susan Bearing 3" "STrVS^ea. S .69 ea.. 4" "STr&O^ea. S .96 ea.. 6"^2rea_jia. 51.73 ea. 12" jBrSS^ea. S5.37 ea. >— Brass Plated Candle Cup is $5r««oo S3.00/10 C $29.40 C Brass & Porcelain Hook $2.97 ea., Brass Plated Hinges t^irj #910 Butt Hinge 'O o =aair6 $fr6«^ea. $.99 ea., S-91-1 #928 Butt Hinge Brass S278«-4P S1.68 10. #F124 Screw tor Above S2.40 c Clipboard Clips 3" S .35 ea 6" S .59 ea.. Plastic Shelf Pins S9r0Q^C $5.40 C, i ________________________Note: C - 100 ._j Catalog St.00 or Iree with order Total Order _ | | Minimum Order is $25.00 MN Res.- 6% Tax _ | Order Amount : Shipping : Shipping _ $25.00 lo $49 99 $3.50 I $50.00 to $99 99 $4 SO I Over $100.00 $5.00 ! GUARANTEE! I j SIGNATURE ___ j CARD NO _ !NAME _ Total Enclosed | |vi»a [^Master Card vka: lADDRESS , I {STATE MEISEL HARDWARE SPECIALTIES P.O. Box 258 J . Mound. Minnesota 55364 • (612) 472 5544 |

||||||||||||||||||||||||||||||||||||||||||||||||||||