Woodworker's Journal 1985-9-2, страница 47

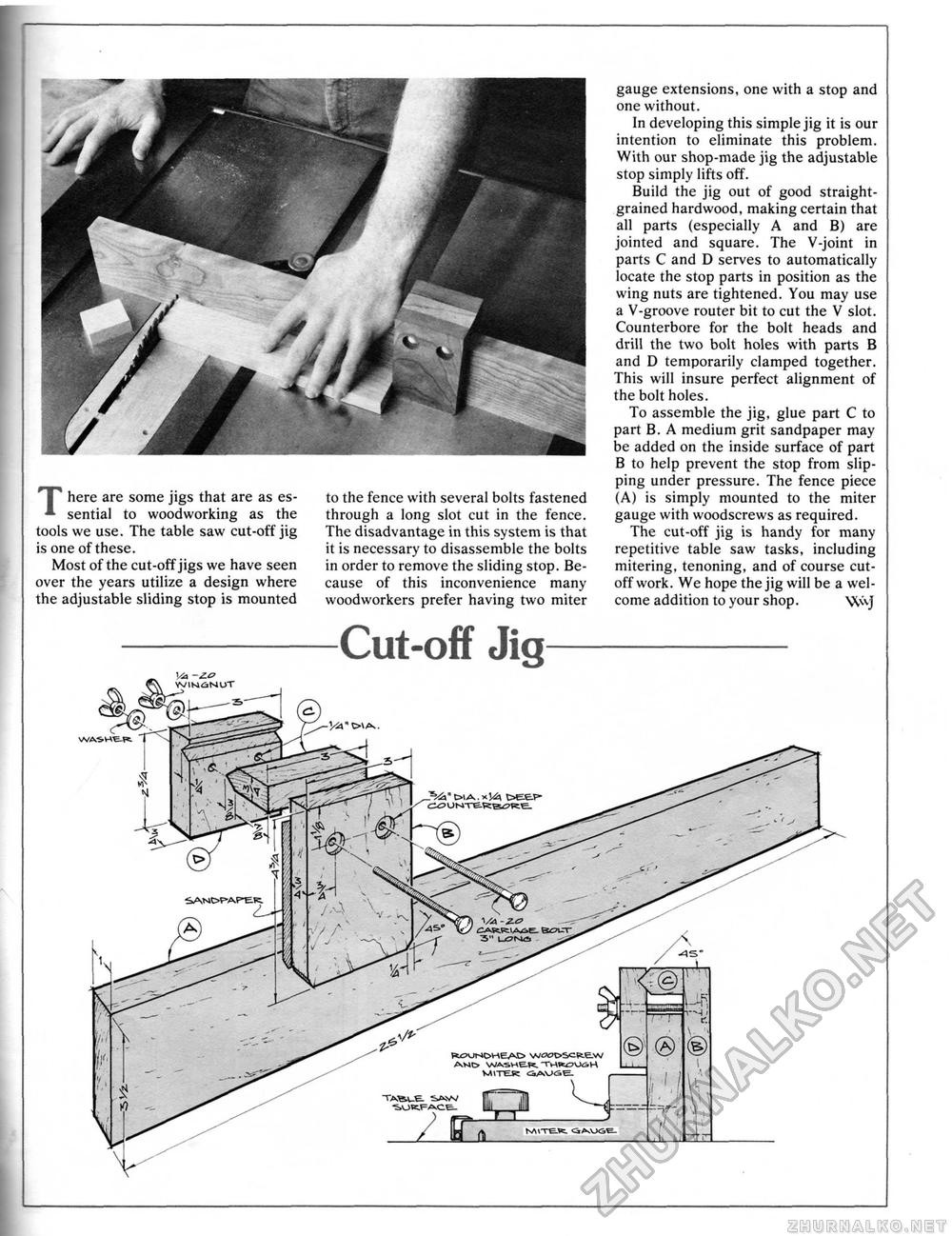

■ ' I' here are some jigs that are as essential to woodworking as the tools we use. The table saw cut-off jig is one of these. Most of the cut-off jigs we have seen over the years utilize a design where the adjustable sliding stop is mounted to the fence with several bolts fastened through a long slot cut in the fence. The disadvantage in this system is that it is necessary to disassemble the bolts in order to remove the sliding stop. Because of this inconvenience many woodworkers prefer having two miter Cut-off Jiggauge extensions, one with a stop and one without. In developing this simple jig it is our intention to eliminate this problem. With our shop-made jig the adjustable stop simply lifts off. Build the jig out of good straight-grained hardwood, making certain that all parts (especially A and B) are jointed and square. The V-joint in parts C and D serves to automatically locate the stop parts in position as the wing nuts are tightened. You may use a V-groove router bit to cut the V slot. Counterbore for the bolt heads and drill the two bolt holes with parts B and D temporarily clamped together. This will insure perfect alignment of the bolt holes. To assemble the jig, glue part C to part B. A medium grit sandpaper may be added on the inside surface of part B to help prevent the stop from slipping under pressure. The fence piece (A) is simply mounted to the miter gauge with woodscrews as required. The cut-off jig is handy for many repetitive table saw tasks, including mitering, tenoning, and of course cutoff work. We hope the jig will be a welcome addition to your shop. V^J -Z.0 WIMliNUT |