Woodworker's Journal 1985-9-2, страница 48

By L. Peter Zeidenstein Blanket Chest Bill Of Materials (All Dimensions Actual) No. No.

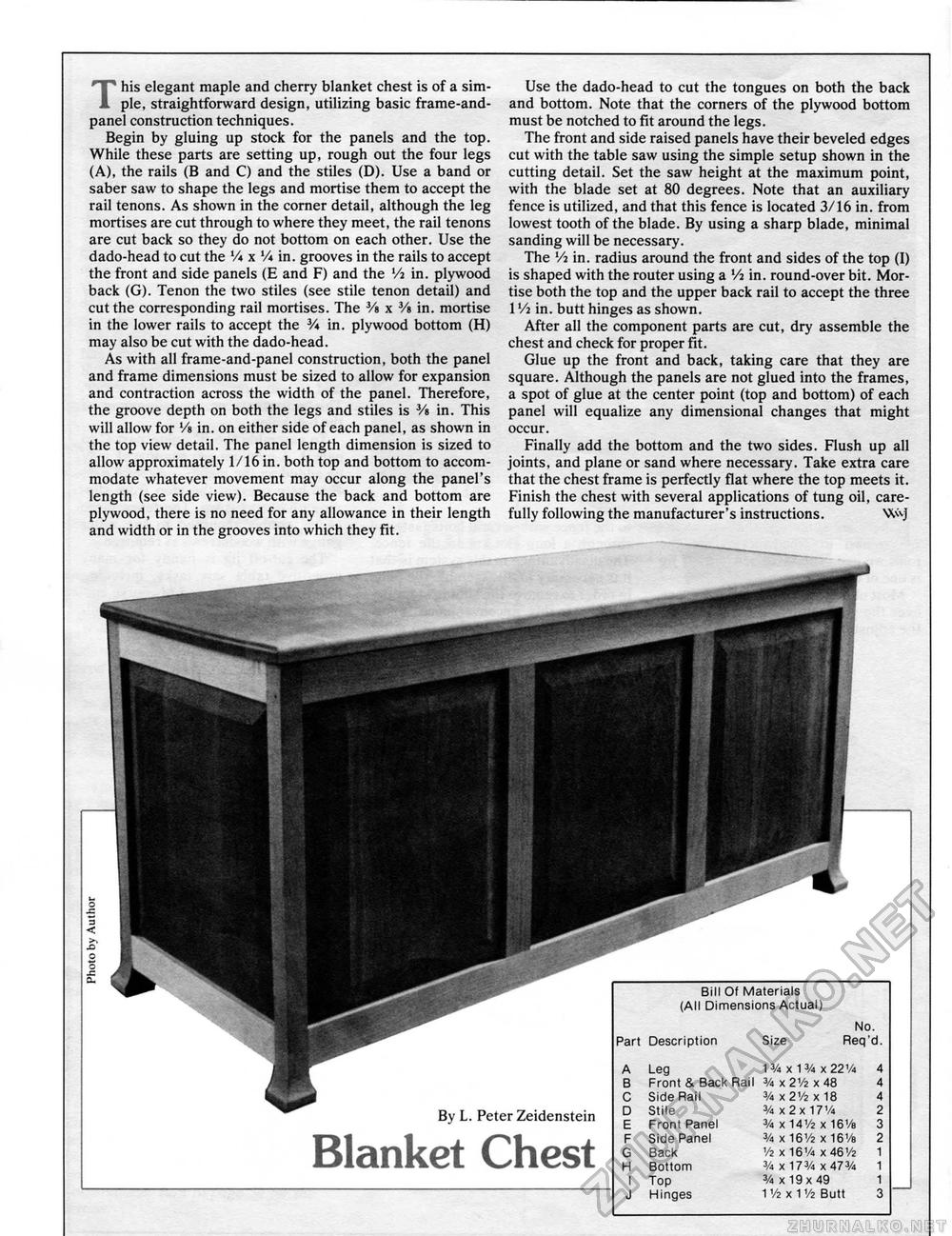

This elegant maple and cherry blanket chest is of a simple, straightforward design, utilizing basic frame-and-panel construction techniques. Begin by gluing up stock for the panels and the top. While these parts are setting up, rough out the four legs (A), the rails (B and C) and the stiles (D). Use a band or saber saw to shape the legs and mortise them to accept the rail tenons. As shown in the corner detail, although the leg mortises are cut through to where they meet, the rail tenons are cut back so they do not bottom on each other. Use the dado-head to cut the V* x V* in. grooves in the rails to accept the front and side panels (E and F) and the Vi in. plywood back (G). Tenon the two stiles (see stile tenon detail) and cut the corresponding rail mortises. The Vs x Vs in. mortise in the lower rails to accept the Va in. plywood bottom (H) may also be cut with the dado-head. As with all frame-and-panel construction, both the panel and frame dimensions must be sized to allow for expansion and contraction across the width of the panel. Therefore, the groove depth on both the legs and stiles is Vs in. This will allow for Vs in. on either side of each panel, as shown in the top view detail. The panel length dimension is sized to allow approximately 1/16 in. both top and bottom to accommodate whatever movement may occur along the panel's length (see side view). Because the back and bottom are plywood, there is no need for any allowance in their length and width or in the grooves into which they fit. Use the dado-head to cut the tongues on both the back and bottom. Note that the corners of the plywood bottom must be notched to fit around the legs. The front and side raised panels have their beveled edges cut with the table saw using the simple setup shown in the cutting detail. Set the saw height at the maximum point, with the blade set at 80 degrees. Note that an auxiliary fence is utilized, and that this fence is located 3/16 in. from lowest tooth of the blade. By using a sharp blade, minimal sanding will be necessary. The Vi in. radius around the front and sides of the top (I) is shaped with the router using a Vi in. round-over bit. Mortise both the top and the upper back rail to accept the three 1 Vi in. butt hinges as shown. After all the component parts are cut, dry assemble the chest and check for proper fit. Glue up the front and back, taking care that they are square. Although the panels are not glued into the frames, a spot of glue at the center point (top and bottom) of each panel will equalize any dimensional changes that might occur. Finally add the bottom and the two sides. Flush up all joints, and plane or sand where necessary. Take extra care that the chest frame is perfectly flat where the top meets it. Finish the chest with several applications of tung oil, carefully following the manufacturer's instructions. Wvj |

||||||||||||||||||||||||||||||||||||||||||||