Woodworker's Journal 1985-9-3, страница 23

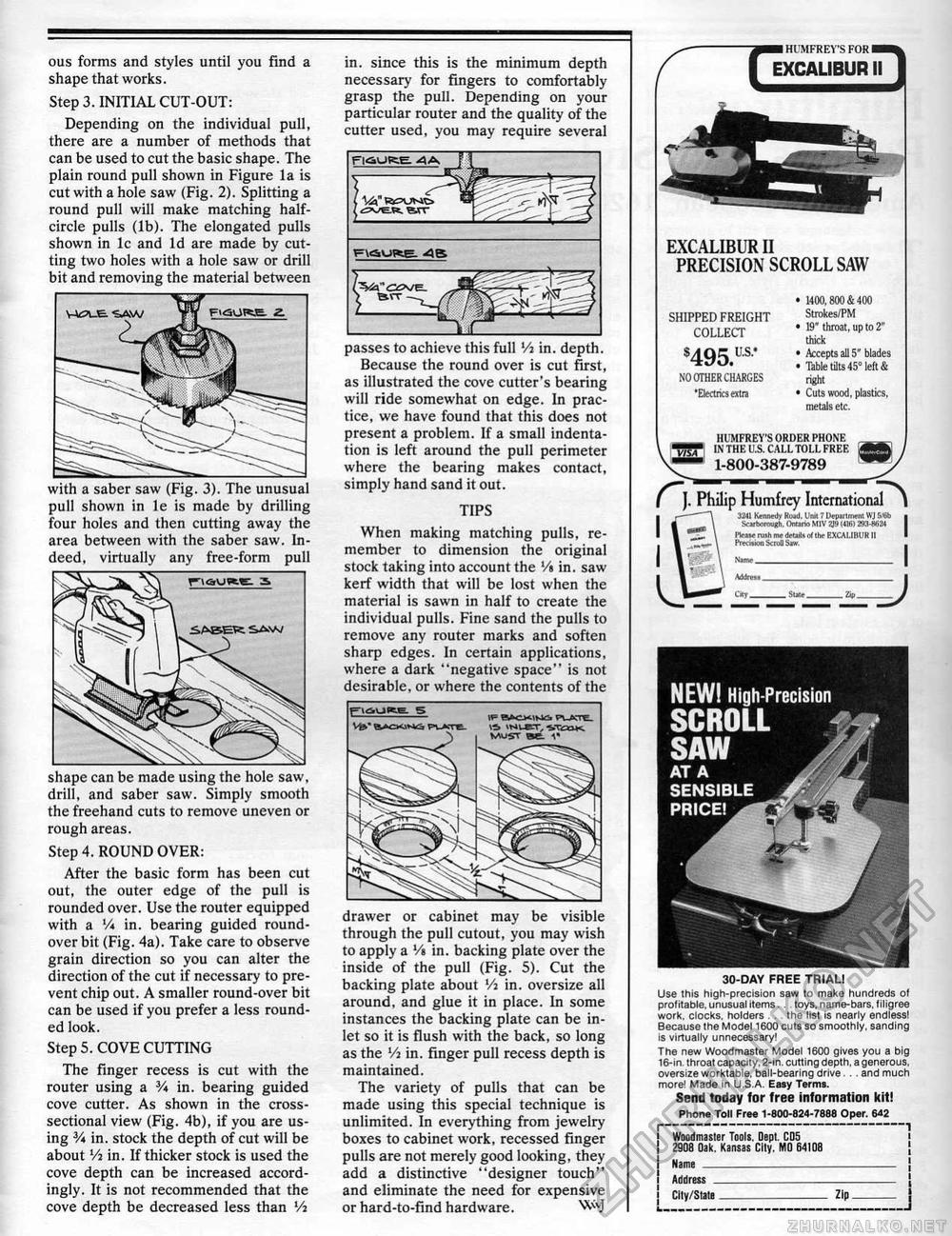

WootSmasler Tools. Dept. CDS 2908 Oak. Kansas City. MO 84108 Name__-__ Address _______ City/State_ Zip. ous forms and styles until you find a shape that works. Step 3. INITIAL CUT-OUT: Depending on the individual pull, there are a number of methods that can be used to cut the basic shape. The plain round pull shown in Figure la is cut with a hole saw (Fig. 2). Splitting a round pull will make matching half-circle pulls (lb). The elongated pulls shown in lc and Id are made by cutting two holes with a hole saw or drill bit and removing the material between shape can be made using the hole saw, drill, and saber saw. Simply smooth the freehand cuts to remove uneven or rough areas. Step 4. ROUND OVER: After the basic form has been cut out, the outer edge of the pull is rounded over. Use the router equipped with a V* in. bearing guided round-over bit (Fig. 4a), Take care to observe grain direction so you can alter the direction of the cut if necessary to prevent chip out. A smaller round-over bit can be used if you prefer a less rounded look. Step 5. COVE CUTTING The finger recess is cut with the router using a V* in. bearing guided cove cutter. As shown in the cross-sectional view (Fig. 4b), if you are using % in. stock the depth of cut will be about Vi in. If thicker stock is used the cove depth can be increased accordingly. It is not recommended that the cove depth be decreased less than Vi in. since this is the minimum depth necessary for fingers to comfortably grasp the pull. Depending on your particular router and the quality of the cutter used, you may require several passes to achieve this full Vi in. depth. Because the round over is cut first, as illustrated the cove cutter's bearing will ride somewhat on edge. In practice, we have found that this does not present a problem. If a small indentation is left around the pull perimeter where the bearing makes contact, simply hand sand it out. TIPS When making matching pulls, remember to dimension the original stock taking into account the '/e in. saw kerf width that will be lost when the material is sawn in half to create the individual pulls. Fine sand the pulls to remove any router marks and soften sharp edges. In certain applications, where a dark "negative space" is not desirable, or where the contents of the drawer or cabinet may be visible through the pull cutout, you may wish to apply a Vt in. backing plate over the inside of the pull (Fig. 5). Cut the backing plate about */i in. oversize all around, and glue it in place. In some instances the backing plate can be inlet so it is flush with the back, so long as the Vt in. finger pull recess depth is maintained. The variety of pulls that can be made using this special technique is unlimited. In everything from jewelry boxes to cabinet work, recessed finger pulls are not merely good looking, they add a distinctive "designer touch" and eliminate the need for expensive or hard-to-fmd hardware. ^ 30-DAY FREE TRIAL! Use this high-precision saw to make hundreds of profitable, unusual items. . toys, name-bars, filigree work, clocks, holders . the list is nearly endless! Because the Model 1600 cuts so smoothly, sanding is virtually unnecessary! The new Woodmastar Model 1600 gives you a big 16-in. throat capacity. 2-in. cutting depth, a generous, oversize worktabte, ball-bearing drive . . . and much more! Made in U.S.A. Easy Terms. Send today for free information kit! Phone Toll Free 1-800-824-7888 Oper, 642 EXCALIBURII PRECISION SCROLL SAW SHIPPED FREIGHT COLLECT s495.ls' no other charges 'Electrics extra • 1400, 800 & 400 Strokes/PM • 19" throat, up to 2" thick • Accepts all 5" blades • Table tilts 45° left & right • Cuts wood, plastics, metals etc. with a saber saw (Fig. 3). The . pull shown in le is made by drilling four holes and then cutting away the area between with the saber saw. Indeed, virtually any free-form pull HUMFREY'S ORDEK ['HONE IN THE U.S. CALL TOLL FREE 1-800-387-9789 \. Philip Humfrey International""^ mi Kennedy kind, Unit 7 DsMrtimnl WJ 5,'fib Stirtdftmijl!, Ontario M1V 2Jt Mlfil »WM4 Please rush me detail* nf the BXCMISUH it Pr«n»n ScruD Saw, 1 \ Addnu_ I V Cl,V___ J |