Woodworker's Journal 1985-9-4, страница 18

Special Techniques

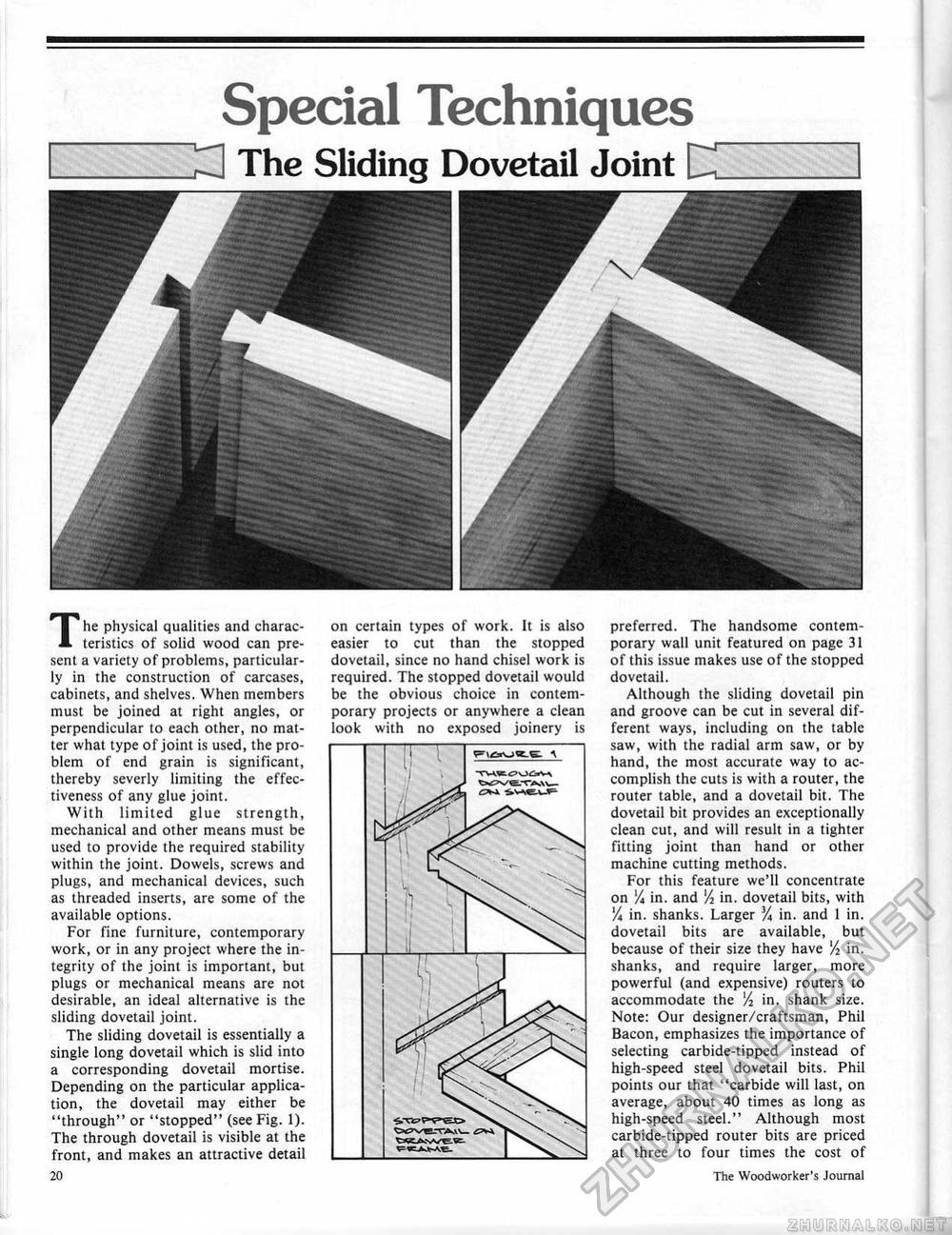

preferred. The handsome contemporary wall unit featured on page 31 of this issue makes use of the stopped dovetail. Although the sliding dovetail pin and groove can be cut in several different ways, including on the table saw, with the radial arm saw, or by hand, the most accurate way to accomplish the cuts is with a router, the router table, and a dovetail bit. The dovetail bit provides an exceptionally clean cut, and will result in a tighter fitting joint than hand or other machine cutting methods. For this feature we'll concentrate on 'A in. and lA in, dovetail bits, with lA in. shanks. Larger % in. and 1 in. dovetail bits are available, but because of their size they have % in. shanks, and require larger, more powerful (and expensive) routers to accommodate the lA in. shank size. Note: Our designer/craftsman, Phil Bacon, emphasizes the importance of selecting carbide-tipped instead of high-speed steel dovetail bits, Phil points our that "carbide will last, on average, about 40 times as long as high-speed steel." Although most carbide-tipped router bits are priced at three to four times the cost of The physical qualities and characteristics of solid wood can present a variety of problems, particularly in the construction of carcases, cabinets, and shelves. When members must be joined at right angles, or perpendicular to each other, no matter what type of joint is used, the problem of end grain is significant, thereby severly limiting the effectiveness of any glue joint. With limited glue strength, mechanical and other means must be used to provide the required stability within the joint. Dowels, screws and plugs, and mechanical devices, such as threaded inserts, are some of the available options. For fine furniture, contemporary work, or in any project where the integrity of the joint is important, but plugs or mechanical means are not desirable, an ideal alternative is the sliding dovetail joint. The sliding dovetail is essentially a single long dovetail which is slid into a corresponding dovetail mortise. Depending on the particular application, the dovetail may either be "through" or "stopped" (see Fig. 1). The through dovetail is visible at the front, and makes an attractive detail on certain types of work. It is also easier to cut than the stopped dovetail, since no hand chisel work is required. The stopped dovetail would be the obvious choice in contemporary projects or anywhere a clean look with no exposed joinery is 20 The Woodworker's Journal |

||||||||