Woodworker's Journal 1985-9-4, страница 19

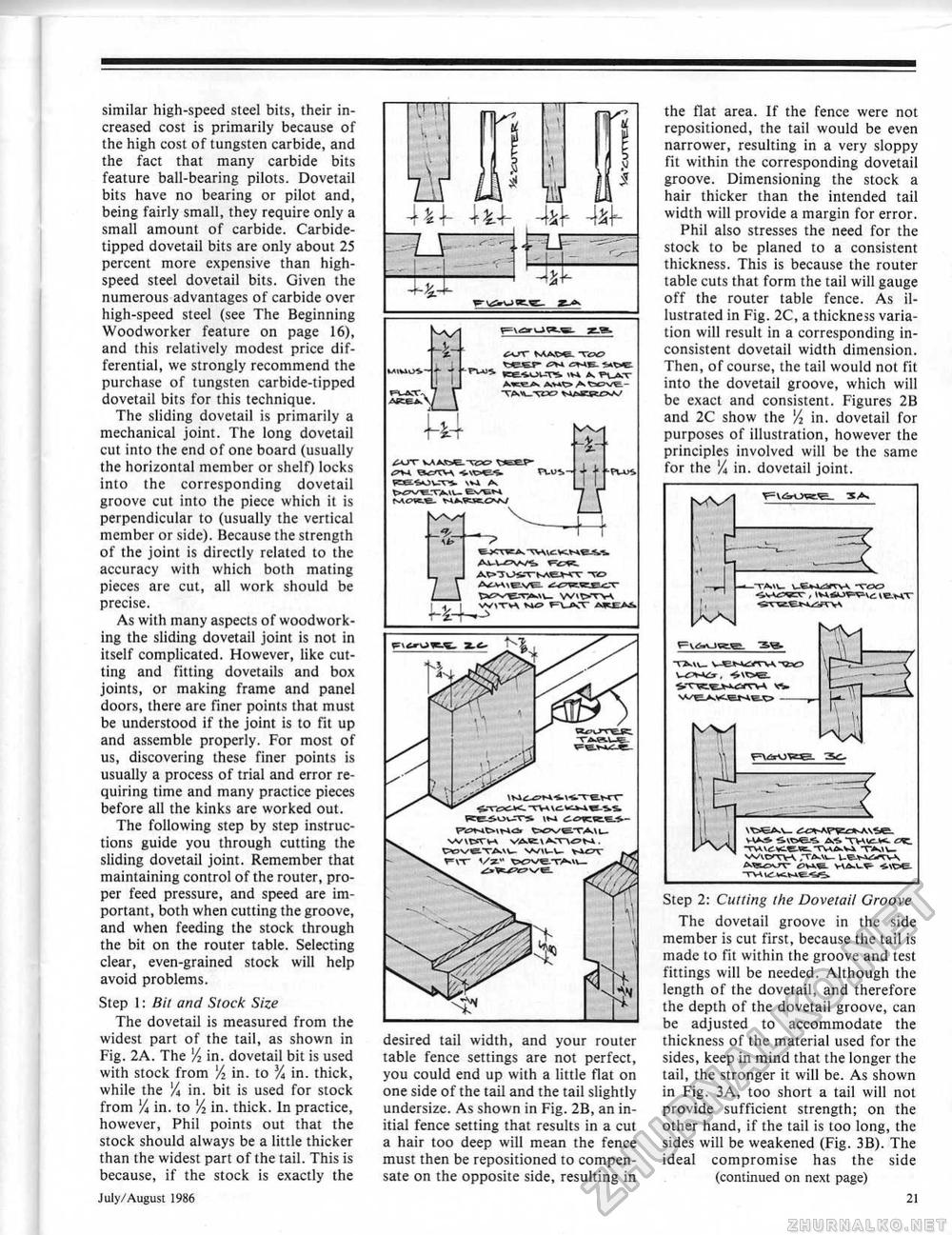

similar high-speed steel bits, their increased cost is primarily because of the high cost of tungsten carbide, and the fact that many carbide bits feature ball-bearing pilots. Dovetail bits have no bearing or pilot and, being fairly small, they require only a small amount of carbide. Carbide-tipped dovetail bits are only about 25 percent more expensive than highspeed steel dovetail bits, Given the numerous advantages of carbide over high-speed steel (see The Beginning Woodworker feature on page 16), and this relatively modest price differential, we strongly recommend the purchase of tungsten carbide-tipped dovetail bits for this technique. The sliding dovetail is primarily a mechanical joint. The long dovetail cut into the end of one board (usually the horizontal member or shelf) locks into the corresponding dovetail groove cut into the piece which it is perpendicular to (usually the vertical member or side). Because the strength of the joint is directly related to the accuracy with which both mating pieces are cut, all work should be precise. As with many aspects of woodworking the sliding dovetail joint is not in itself complicated. However, like cutting and fitting dovetails and box joints, or making frame and panel doors, there arc finer points that must be understood if the joint is to fit up and assemble properly. For most of us, discovering these finer points is usually a process of trial and error requiring time and many practice pieces before all the kinks are worked out. The following step by step instructions guide you through cutting the sliding dovetail joint. Remember that maintaining control of the router, proper feed pressure, and speed are important, both when cutting the groove, and when feeding the stock through the bit on the router table. Selecting clear, even-grained stock will help avoid problems. Step 1: Bit and Stock Size The dovetail is measured from the widest part of the tail, as shown in Fig. 2A. The lA in. dovetail bit is used with stock from in. to % in. thick, while the % in. bit is used for stock from % in. to % in. thick. In practice, however, Phil points out that the stock should always be a little thicker than the widest part of the tail. This is because, if the stock is exactly the J uly/August 1986 desired tail width, and your router table fence settings are not perfect, you could end up with a little flat on one side of the tail and the tail slightly undersize. As shown in Fig. 2B, an initial fence setting that results in a cut a hair too deep will mean the fence must then be repositioned to compensate on the opposite side, resulting in the flat area. If the fence were not repositioned, the tail would be even narrower, resulting in a very sloppy fit within the corresponding dovetail groove. Dimensioning the stock a hair thicker than the intended tail width will provide a margin for error. Phil also stresses the need for the stock to be planed to a consistent thickness. This is because the router table cuts that form the tail will gauge off the router table fence. As illustrated in Fig. 2C, a thickness variation will result in a corresponding inconsistent dovetail width dimension. Then, of course, the tail would not fit into the dovetail groove, which will be exact and consistent. Figures 2B and 2C show the % in. dovetail for purposes of illustration, however the principles involved will be the same for the Vt in. dovetail joint. The dovetail groove in the side member is cut first, because the tail is made to fit within the groove and test fittings will be needed. Although the length of the dovetail, and therefore the depth of the dovetail groove, can be adjusted to accommodate the thickness of the material used for the sides, keep in mind that the longer the tail, the stronger it will be. As shown in Fig. 3A, too short a tail will not provide sufficient strength; on the other hand, if the tail is too long, the sides will be weakened (Fig. 3B). The ideal compromise has the side (continued on next page) 21 lV i\r t_T biTVETMU EVSM 1-AOTtC- NMtSWW TCW7 K^SiOU-V". A, Pl_jtkT-MDCA ^totsvt- |