Woodworker's Journal 1985-9-5, страница 16

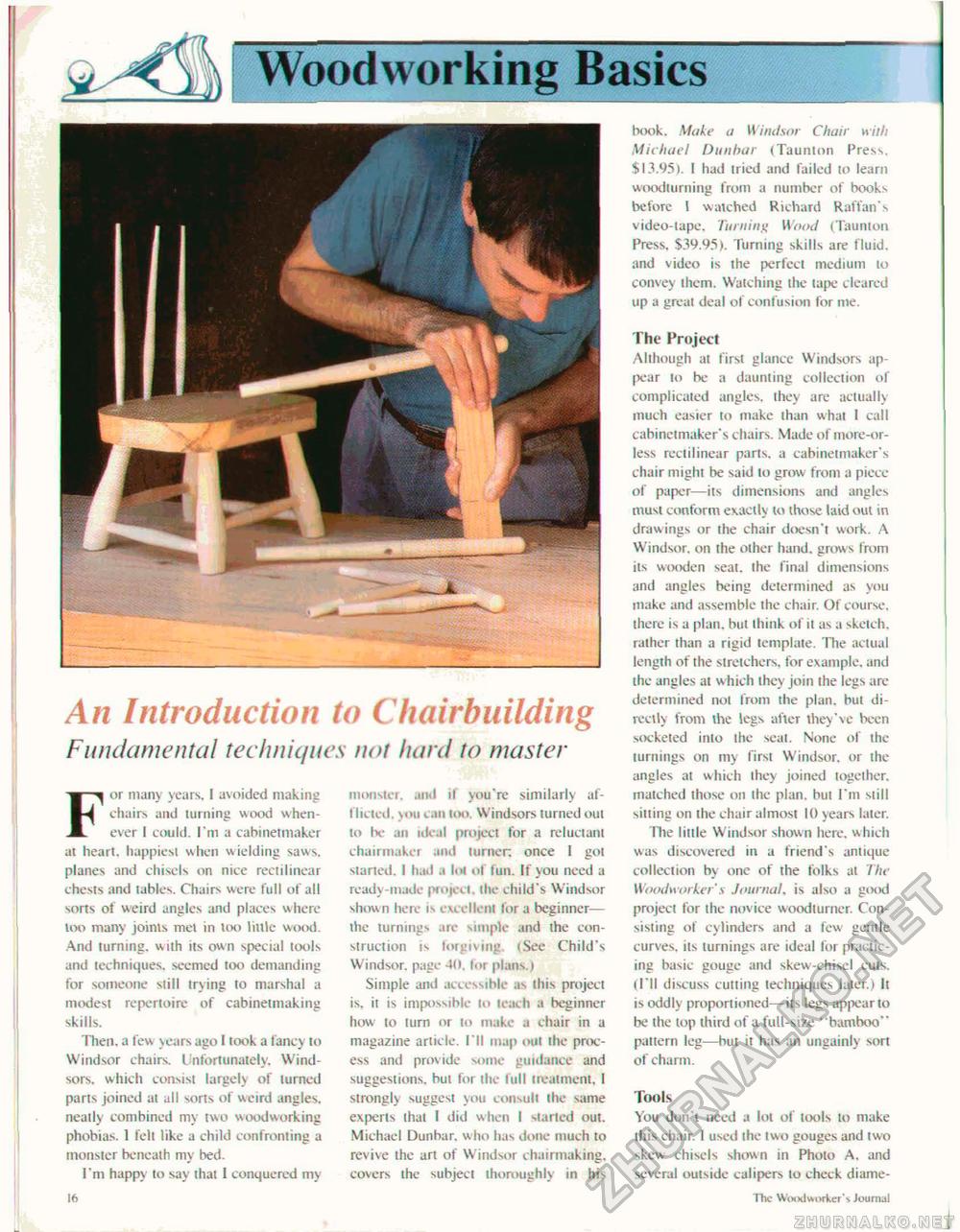

I Woodworking BasicsAn Introduction to Chairbuilding Fundamental techniques not hard to master For many years, f avoided making chairs and turning wood whenever I could. I'm a cabinetmaker at heart, happiest when wielding saws, planes and chisels on nice rectilinear chests and tables. Chairs were full ol" all sorts ot weird angles and places where too many joints met in too little wood. And turning, with its own special tools and techniques, seemed too demanding for someone Mill trying to marshal a modest repertoire of cabinetmaking skills. Then, a few \ears ago I took a fancy to Windsor chairs. Unfortunately, Windsors, which consist largel} of turned parts joined at all sorts of weird angles, neatly combined my two woodworking phobias. 1 felt like a child confronting a monster beneath my bed. I'm happy to say that I conquered my 16 monster, and it you're similarly af-I licicd. you i an too. Windsors turned out lo he an ide.il project for a reluctant chairmakcr and turner: once I got started. I had a lot of fun. If you need a ready-made project, Ihe child's Windsor shown here is excellent for a beginner— the turning-, are simple and the construction is forgiving (See Child's Windsor, page 40, for plans. J Simple and accessible as this project is, it is impossible lo leach a beginner how to turn or to make a chair in a magazine article. I'll map out the process and provide some guidance and suggestions, but for the lull treatment. I strongly suggest you consult the same experts that I did when I started out. Michael Dunbar, who has done much to revive the art of Windsor chairmaking. covers the subject thoroughly in his book. Make a Windsor Chair with Michael Dunbar (Taunton Press, $13.95). I had tried and failed to learn woodturning from a number of books before I watched Richard Raffan's video-tape. Turning Wood (Taunton Press, S39.95). Turning skills are fluid, and video is (he perfect medium to convey (hem. Watching the tape cleared up a great deal of confusion for me. The Project Although at first glance Windsors appear to be a daunting collection of complicated angles, they are actually much easier to make than what I call cabinetmaker's chairs. Made of more-or-less rectilinear parts, a cabinetmaker's chair might be said lo grow from a piece of paper—its dimensions and angles must conform exactly lo those laid out in drawings or the chair doesn't work. A Windsor, on the other hand, grows from ils wiMKien seat, Ihe final dimensions and angles being determined as you make and assemble the chair. Of course, (here is a plan, but (hink of it as a sketch, rather than a rigid template. Hie actual length of the stretchers, for example, and the angles at which they join ihe legs are determined not from the plan, but directly from the legs afteT they've been socketed into the seal. None of the turnings on my first Windsor, or the angles ai which they joined together, matched those on ihe plan, but I'm still silting on the chair almost 10 years later. Hie luile Windsor shown here, which was discovered in a friend's antique collection by one of the folks at The Woodworker'Journal, is also a good project for the novice woodturner. Consisting of cylinders and a few gentle curves, its turnings are ideal for practicing basic gouge and skew-chisel euls. (I'll discuss cutting techniques later.) It is oddly proportioned—its legs appear to be (he top third of a full-size bamboo" pattern leg—but it has an ungainly sort of charm. Tools You don't need a lot of tools to make (his chair. I used the two gouges and two skew chisels shown in Photo A. and several outside calipers to check diame-Thc Woodvwiier's Journal |