Woodworker's Journal 1985-9-5, страница 19

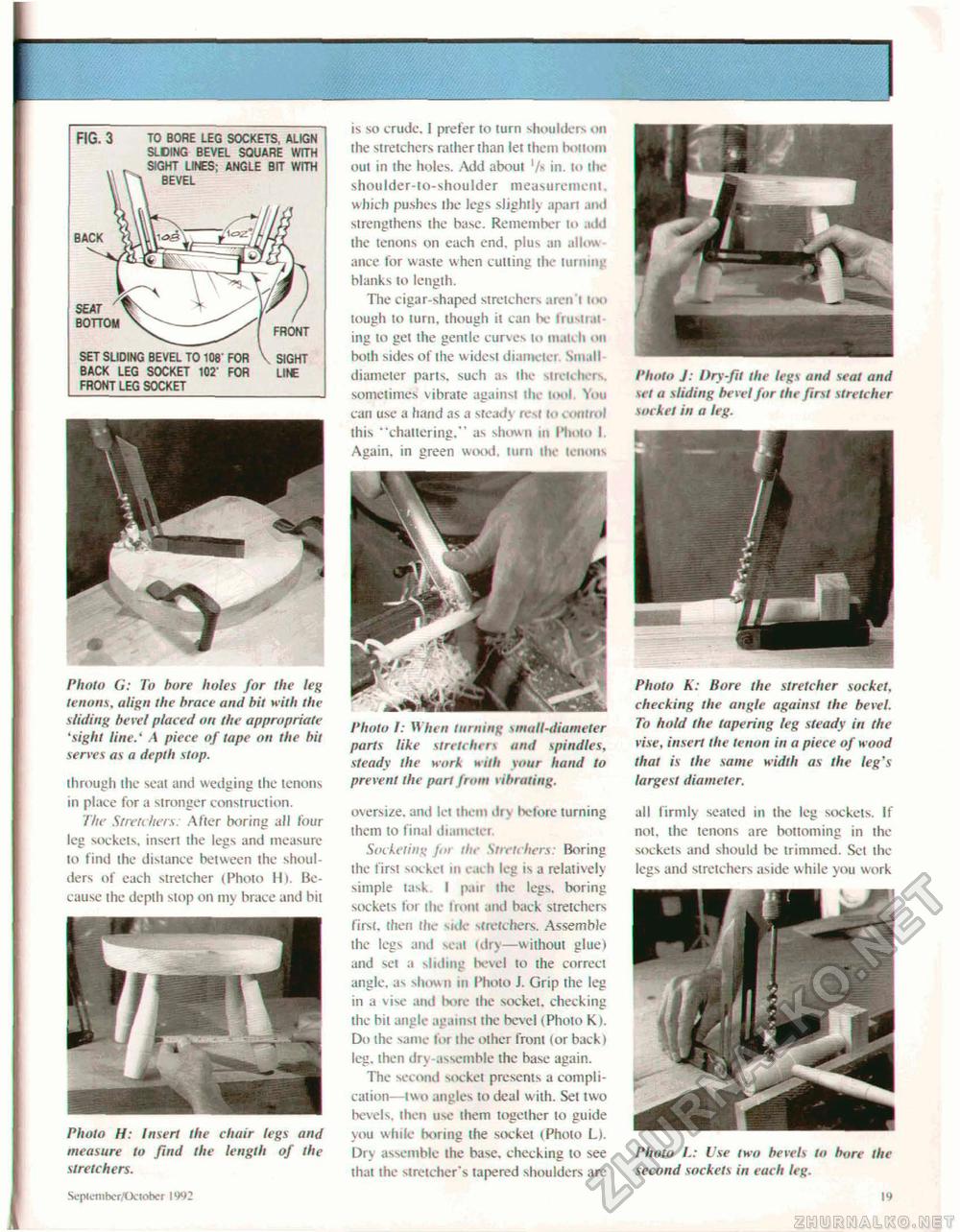

Photo I: When turning small-diameter parts like stretchers and spindles, steady the work with your hand to prevent the part from vibrating. oversize. and let them di v before turning them to final diameter. Socketing Joi the Siren hers: Boring the first socket in c.ich leg is a relatively simple task. I pair the legs, boring sockets tor the front and back stretchers first, then the side stretchers. Assemble the legs and seal (dry—without glue) and set a sliding bevel to the correct angle, as shown in Photo J. Grip the leg in a vise and bore the socket, checking the bit angle against the bevel (Photo K). Do the same for the other front (or back) leg. then dr\ -assemble the base again. The second socket presents a complication- two angles to deal with. Set two bevels, then use them together to guide you while boring the socket (Photo Ll. Dry assemble Ihe base, checking to see that the stretcher's tapered shoulders are is so crude. 1 prefer to turn shoulders on the stretchers rather than let them bottom out in the holes. Add about '/s in. to the shoulder-to-shoulder measurement, which pushes the legs slightly apart and strengthens ihe base. Remember to add the tenons on each end, plus an all«>w ance for waste w hen culling the turning blanks to length. The cigar-shaped stretchers aren't too lough to turn, though it can be trust I at ing lo get the gentle curves lo match on both sides of the widest diantciei Small diameter parts, such as Ihe stretchers, sometimes vibrate against the tool You can use a hand as a steady resi 10i ontrol this "chattering." as shown hi Pholo I Again, in green wood, turn the tenons I'hoto J: Dry-fit the legs and seal and set a sliding bevel for the first stretcher socket in a leg. Photo H: Insert the chair legs and measure to find the length of the stretchers. September/October 1992 19 Photo L: Use two bevels to bore the second sockets in each leg. Photo G: To bore holes for the leg tenons, align the brace and hit with the sliding bevel placed an the appropriate 'sight line.' A piece of tape on the bit serves as a depth stop. through the seat and wedging the tenons in place for a stronger construction. The Stretchers: After boring all four leg sockets, insert the legs and measure to find the distance between the shoulders of each stretcher (Photo Hi. Because the depth stop on my brace and bit Photo K: Bore the stretcher socket, checking the angle against the bevel. To hold (he tapering leg steady in the vise, insert the tenon in a piece of w ood that is the same width as the leg's largest diameter. all firmly sealed in the leg sockets. If not. the tenons are bottoming in the sockets and should be trimmed. Set the legs and stretchers aside while you work BACK FIG. 3 TO BORE LEG SOCKETS, ALIGN SLDING BEVEL SQUARE WITH SIGHT LINES; ANGLE BIT WITH BEVEL SEAT BOTTOM FRONT SET SLIDING BEVEL TO 108' FOR BACK LEG SOCKET 102' FOR FRONT LEG SOCKET SIGHT LINE |