Woodworker's Journal 1985-9-5, страница 18

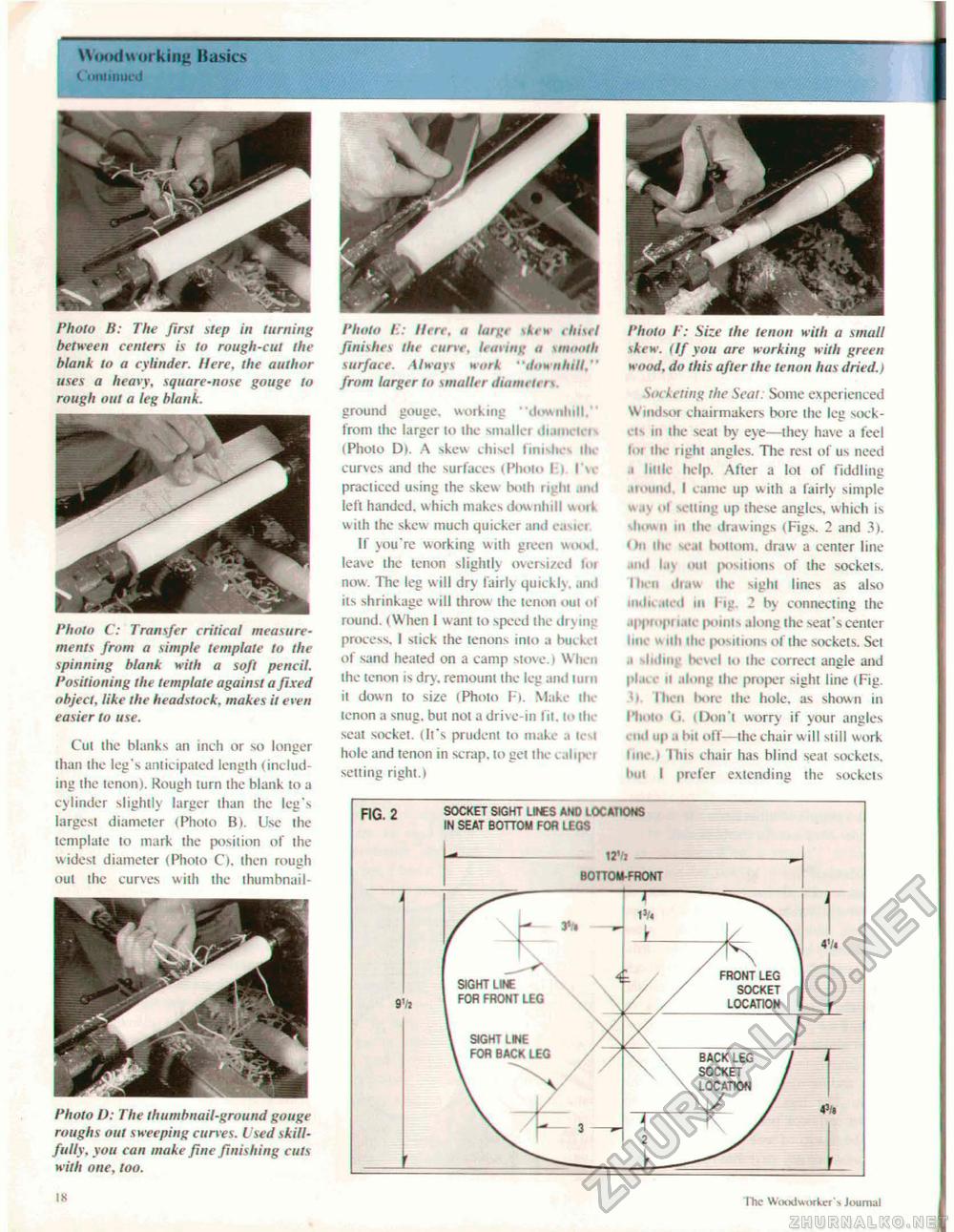

Woodworking Musics Ci untuned Photo B: The first step in turning between centers is to rough-cut Ihe blank lo a cylinder. Here, the author uses a heavy, square-nase gouge to rough out a leg blank. Photo C: Transfer critical measurements from a simple template to the spinning blank with a soft pencil. Positioning the template against a fixed object, like the headstock. makes it even easier to use. Cul the blanks an inch or so longer than the leg's anticipated length (including the tenon). Rough turn the blank to a cylinder slightly larger than the leg's largest diameter (Photo B). Use the template to mark the position of the widest diameter (Photo C). then rough out the curves with the thumbnail- Photo L): The thumbnail-ground gouge roughs out sweeping curves. L sed skillfully, you can make fine finishing cuts with one, too. Photo I:: Here, a large \kew chisel finishes the curve, leaving a smooth surface. Always work "downhill," from larger lo smaller diameters. ground gouge, working "downhill." from the larger to the smaller diameu-is (Photo D). A skew chisel finishes ilt> curves and the surfaces (Photo I t IV practiced using the skew both righi .tnd left handed, which makes downhill vuul w ith the skew much quicker and easiei If you're working with green wood, leave the tenon slightly oversized toi now. The leg will dry fairly quickly, and its shrinkage will throw the tenon out of round. (When 1 w ant to speed the drying process. I stick the tenons into a bucket of sand heated on a camp stove.) W hen the tenon is dry. remount the leg and turn it down to size (Photo F). Make the tenon a snug, but not a drive-in fil. lo the seat socket. (It's prudent to make a icsi hole and tenon in scrap, to gel the calipci setting right.) I'hato /•'; Size Ihe tenon with a small skew. (If you are working with green wood, do this after the tenon lias dried.) Socketing the Seat: Some experienced W mdsor chairmakers bore the leg sockets in ihe seat by eye—they have a feel lot ihe right angles. The rest of us need i link* help. After a loi of fiddling around, I came up with a fairly simple <>| selling up these angles, which is sImimi iii the draw ings (Figs. 2 and 3). On ilu seal bottom, draw a center line ind l.iy mil positions of the sockets. Mien diaw the sight lines as also mdi< iii il hi Hg. 2 b\ connecting the .i|'|iii.|>n,iu jxiinis along the seat's center line iih the positions of the sockets. Set i h lin iwcl to ihe correct angle and plui i- n along the proper sight line (Fig. ■■' I lien bore the hole, as shown in I1i«ito (I iDon't worry if your angles end up a bit off—the chair will siill work line i Pus chair has blind seat sockets, bul I prefer extending the sockets IK The Woodworker's Journal |