Woodworker's Journal 1985-9-5, страница 24

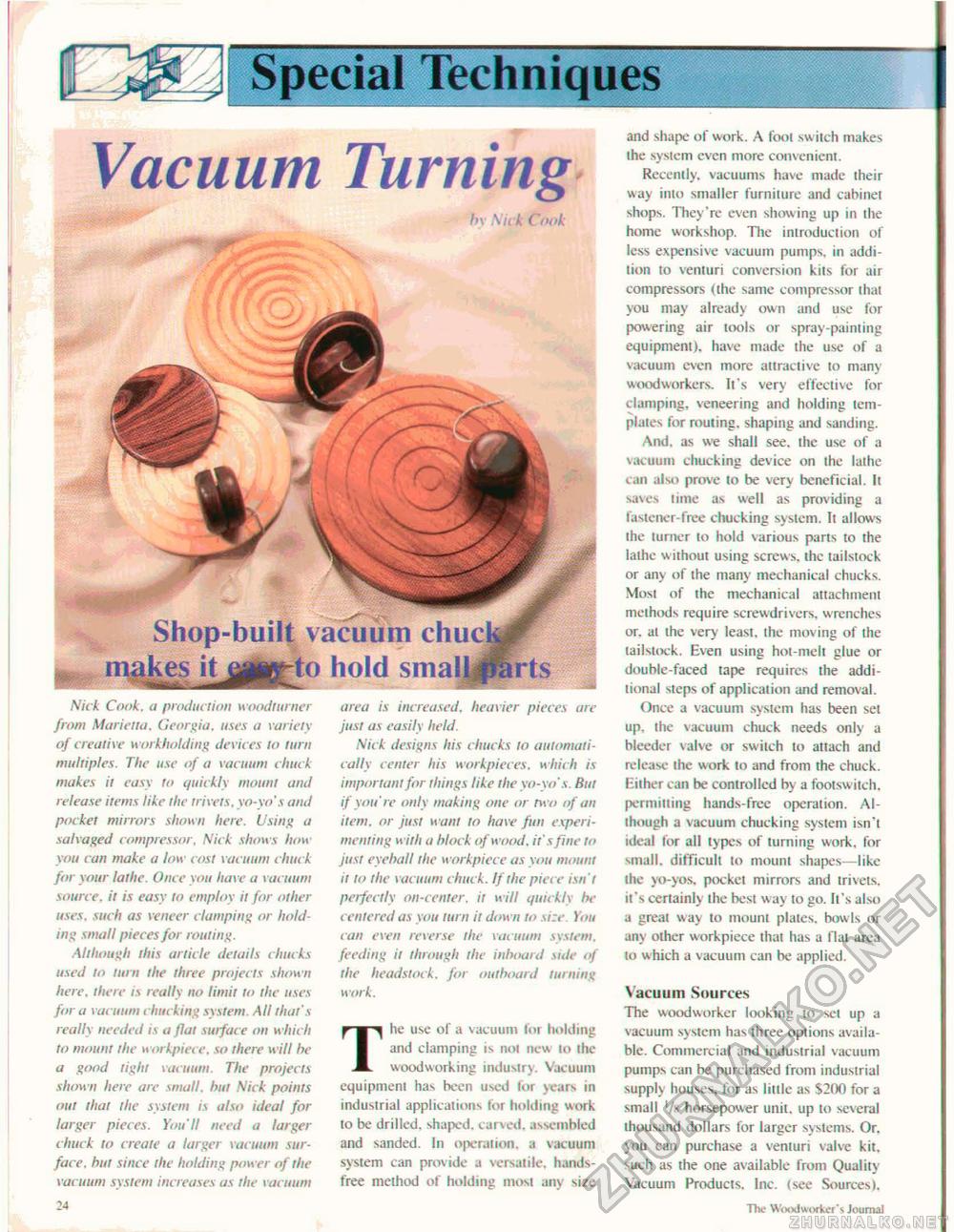

I Special Techniques—— Vacuum Turning h\ Aiiik Conk Shop-built vacuum chucl ;es it v\mr tn hold small riarts Atick Cook, a production woodturner from Marietta. Georgia, uses a variety of creative workliolding devices to turn multiples. The use of a vacuum chuck makes it easy to quickly mount and release items like the trivets, yo-yo's and pocket mirrors shown here. Using a salvaged compressor, Nick shows how you can make a low cost vacuum chuck for your lathe. Once you have a vacuum source, it is easy to employ it for other uses, such as veneer clamping or holding small pieces for routing. Although this article details chucks used to turn the three projects shown here, there is really no limit to the uses for a vacuum chucking system. All that's really needed is a flat surface on which to mount the workpiece, so there will he a good tight vacuum. The projects shown here are small, hut Nick points out that the system is also ideal for larger pieces. You'll need a larger chuck to create a larger vacuum surface. hut since the holding power of the vacuum system increases as the vacuum 24 area is increased, heavier pieces are just as easily held. Nick designs his chucks lo automatically center his workpieces. which is important for things like the yo-yo's. But if you're only making one or two of an item, or just want to have fun experimenting with a block of wood, it's fine to just eyeball the workpiece as you mount it to the vacuum chuck. If the piece isn't perfectly on-center, it will quickly be centered as you turn it down to size. You can even reverse the vacuum system, feeding it through the inboard side of the head stock, for outboard turning work. The use of a vacuum for holding and clamping is noi new lo ihe woodworking industry. Vacuum equipment has been used for years in industrial applications for holding work to be drilled, shaped, carved, assembled and sanded. In operation, a vacuum system can provide a versatile, hands-free method of holding most any size and shape of work. A foot sw itch makes ihe system even more convenient. Recently, vacuums have made their way into smaller furniture and cabinet shops. They're even showing up in the home workshop. The introduction of less expensive vacuum pumps, in addition to venturi conversion kits for air compressors (the same compressor thai you may already own and use for powering air tools or spray-painting equipment), have made the use of a vacuum even more attractive to many woodworkers. It's very effective for clamping, veneering and holding templates for routing, shaping and sanding. And. as we shall see. ihe use of a vacuum chucking device on the lathe can also prove to be very beneficial. It saves time as well as providing a fastener-free chucking system. It allows the turner to hold various parts to the lathe w ithout using screw s, ihe tailstock or any of the many mechanical chucks. Most of the mechanical attachment methods require screwdrivers, wrenches or. ai the very least, the moving of the tailstock. Even using hot-melt glue or double-faced tape requires the additional steps of application and removal. Once a vacuum system has been set up, ihe vacuum chuck needs only a bleeder valve or switch to attach and release the work to and from the chuck. Either can be controlled by a footswitch. permitting hands-free operation. Although a vacuum chucking system isn't ideal for all types of turning work, for small, difficult to mount shapes—like ihe yo-yos. pockei mirrors and trivets, it's certainly the best way to go. It's also a great way to mount plates, howls or any other workpicce that has a flat area lo which a vacuum can be applied. Vacuum Sources The woodworker looking lo set up a vacuum system has three options available. Commercial and industrial vacuum pumps can be purchased from industrial supply houses, for as little as $200 for a small '/x horsepower unit, up lo several thousand dollars for larger systems. Or. you can purchase a veniuri valve kit. such as the one available from Quality Vacuum Products. Inc. (see Sources). The Woodworker's Journal |