Woodworker's Journal 1985-9-5, страница 29

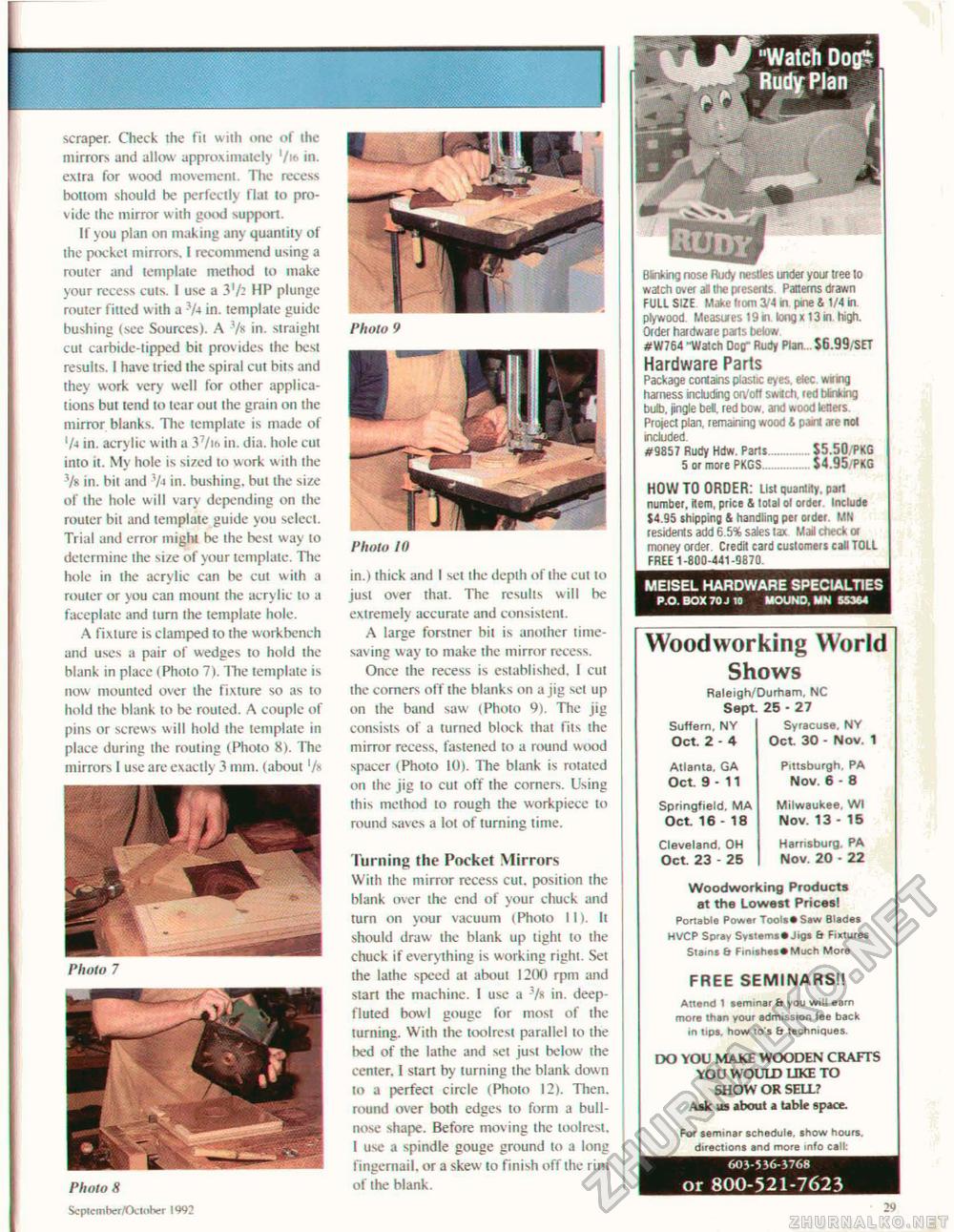

scraper. Check the fit with one of the mirrors and allow approximately l/\t in. extra for wood movement. The recess bottom should be perfectly flal to provide the mirror with ginxl support. If you plan on making any quantity of the pocket mirrors. I recommend using a router and template method to make your recess cuts. 1 use a V/2 HP plunge router fitted with a V> in. template guide bushing (sec Sources). A 3/k in. straight cut carbide-tipped bit provides the best results. I have tried the spiral cut bits and they work very well for other applications but tend to tear out the grain on the mirror blanks. The template is made of '/•» in. acrylic with a 37/ih in. dia. hole cut into it. My hole is sized to work w ith the 3/ft in. bit and 'A in- bushing, but the size of the hole will vary depending on the router bit and template guide you select. Trial and error might be the best way to determine the size of your template. The hole in the acrylic can be cut with a router or you can mount the acrylic to a faceplate and turn the template hole. A fixture is clamped to the workbench and uses a pair of wedges to hold the blank in place (Photo 7). The template is now mounted over the fixture so as to hold the blank to be routed. A couple of pins or screws will hold the template in place during the routing (Photo 8). The mirrors I use are exactly 3 mm. (about '/» Photo 7 Photo 8 September/October 1992 Plwto 10 in. ) thick and I set the depth of the cut lo just over that. The results will be extremely accurate and consistent. A large forstner bit is another time-saving way to make the mirror recess. Once the recess is established, 1 cut the corners off the blanks on a jig set up on the band saw (Photo 9). The jig consists of a turned block that fits the mirror recess, fastened to a round wood spacer (Photo 10). The blank is rotated on the jig to cut off the corners. Using this method to rough the workpiece to round saves a lot of turning time. Turning the Pocket Mirrors With the mirror recess cut. position the blank over the end of your chuck and turn on your vacuum (Photo II). li should draw the blank up tight to the chuck if everything is working right. Set the lathe speed at about 1200 rpm and start the machine. I use a 3/s in. deep-fluted bowl gouge for most of the turning. With the toolrest parallel lo the bed of the lathe and sel jusi below the center. 1 start by turning the blank down to a perfect circle (Photo 12). Then, round over both edges to form a bull-nose shape. Before moving the toolrest, 1 use a spindle gouge ground to a long fingernail, or a skew to finish off ihe rim of the blank. Blinking nose Rudy nestles under your tree lo waich over all the presents. Patterns drawn FULL SIZE Make from 3/4 n pure & 1/4 in plywood Measures 19 in long x 13 in. high. Order hardwafe pans below #W764 "Watch Dob" Rut* S6.99/SET Hardware Parts Package contains plaslic eyes, etec wmng harness including on/off switch, ted blinking bulb, jingle be*, red bow, and wood letters. Project plan, remaining wood 4 paint are nol Included. #9857 Rudy Hdw. Parts......55.50 PKG 5 or more PKGS.......„.„... S4.95/PKG HOW TO ORDER: list quantity, part number, item, price & total ol order. Include £4.95 shipping & handling per order. MN residents add 6 5% sales tax Mail check or money order. Credit card customers call TOLL FREE 1-800-441-9870. meisel hardware specialties P.O. BOX 70 J 10 MOUND, UN SUM Woodworking World Shows Raleigh/Durham, NC Sept. 25 • 27 Suffern. NY Oct. 2 - 4 Atlanta, GA Oct 9-11 Springfield. MA Oct. 16 - 18 Cleveland. OH Oct. 23 - 25 Syracuse, NV Oct. 30 - Nov. 1 Pittsburgh. PA Nov. 6 - 8 Milwaukee, Wl Nov. 13 - 15 Harnsburg. PA Nov. 20 - 22 Woodworking Products at the Lowest Prices! Portable Power Tools* Saw Blades HVCP spray Systems* Jig' & Fixtures Stains & Finishes* Much More FREE SEMINARS!! Attend 1 seminar & you will earn more itian your admission fee back in lips, how lo's & techniques. DO YOU MAKE WOODEN CRAFTS YOU WOULD LIKE TO SHOW OR SELL? Ask us about a table space. For seminar schedule, show hours, directions end more info call: 60J-536-3768 or 800-521-7623 29 |