Woodworker's Journal 1985-9-6, страница 30

6- RtflNISHING PRODUCTS RANDOM ORBITAL DISCS S- White Hoo» A loop 6 tar BOSCH 180 Gnt $12 50/50 2*C Gnt$ 10 00/50 6" Wriiif v 'tm'i PSA Discs • 220 Gdl $20 00/250 Roll PREMIUM QUALITY BELTS BEST RESIN OVER RESIN. X WEIGHT 10 BO* 1i« 3m8 Ji21 3«24 701 75 75 BO 85 4i21 or 4i21»» 4K24 4*36 6x48 6x89 $ -95 ea 1.05 1 30 300 5.60 ADHESIVE CLOTH DISCS: BEST RESIN OVER RESIN, "X" WEIGHT 5" diameter S80ea 9" $i80ea. 6* 90 10" 2 00 8" 140 12- 2 50 Pnces quotsd 60 oltui jmj iwtibie 9**11* PAPER SHEETS

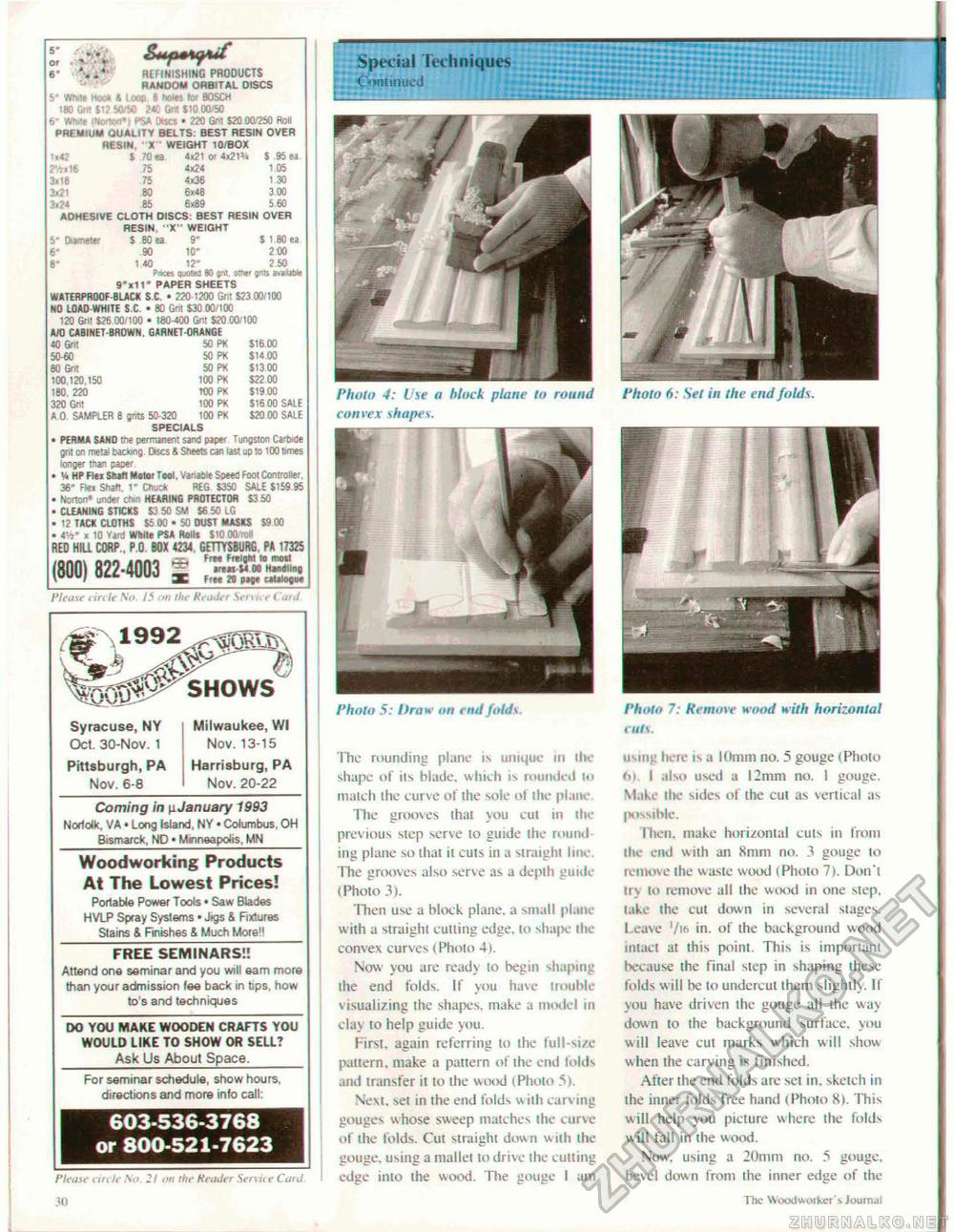

SPECIALS • PERM* SAND me permanent sand paper Tunjston Carbide ;r,t on metai backing. Discs & Steels can las! up to 100 times ■onger ttian paper • V< HP Flei Shaft Motor Tool. VanaWe Speed Fooi Controller. 36" hex Shaft, T Chuck REG S350 SALE $159 95 • Norton* under chin HEARING PROTECTOR $3 50 • CLEANING STICKS S3 50 SM $6 50 LG . 12 TACK CLOTHS $5 00 • 60 OUST MASKS 59 00 • 4Vj" i 10 Van' White PSA Rolls $10 OOrrHi RED HILL CORP.. P.O. MX itU GETTYSBURG PA 1732S SPECIALS • PERM* SAND me permanent sand paper Tunjston Carbide ;r,t on metai backing. Discs & Steels can las! up to 100 times ■onger ttian paper • V< HP Flei Shaft Motor Tool. VanaWe Speed Fooi Controller. 36" hex Shaft, T Chuck REG S350 SALE $159 95 • Norton* under chin HEARING PROTECTOR $3 50 • CLEANING STICKS S3 50 SM $6 50 LG . 12 TACK CLOTHS $5 00 • 60 OUST MASKS 59 00 • 4Vj" i 10 Van' White PSA Rolls $10 OOrrHi RED HILL CORP.. P.O. MX itU GETTYSBURG PA 1732S (800) 822-4003 I WOL. Please circle Sir IS r»< llie Header Serru < Card .sV\ 1992 ' SHOWS Syracuse, NY Oct. 30-Nov. 1 Pittsburgh, PA Nov. 6-8 Milwaukee, Wl Nov. 13-15 Harrisburg, PA Nov. 20-22 Coming in)-.January 1993 Norfolk, VA * Long Island, NV • Columbus, OH Bismarck, NO * Mnneapdis. MN Woodworking Products At The Lowest Prices! Portable Power Tools • Saw Blades HVLP Spray Systems • Jigs & Fixtures Stains & Finishes & Much More'! FREE SEMINARS!! Attend one seminar and you will dam more than your admission lee back in bps, how to's and techniques DO YOU MAKE WOODEN CRAFTS YOU WOULD LIKE TO SHOW OR SELL? Ask Us About Space._ For seminar schedule, show hours, directions and more info call: 603-536-3768 or 800-521-7623 Photo 4: Use « hloek plane to round convex shapes. Photo 6: Set in the end folds. Please circle So. 21 on The Header Service Card •4K Photo 5: l>raw on md folds. The rounding plane is unique in llie shape of its blade, which is rounded to match the curve of the sole of the plane. The grooves that you cut in the previous step serve to guide the rounding plane so that it cuts in a straight line. The grooves also serve as a depth guide (Photo 3). Then use a block plane, a small plane with a straight cutting edge, lo shape the convex curves (Photo 4). Now you are ready to begin shaping the end folds. If you have trouble visualizing the shapes, make a model in clay to help guide you. First, again referring to ihe full-size pattern, make a pattern of ihe end folds and transfer it to the wood iPholo 5). Next, set in the end folds wilh carving gouges whose sweep matches the curve of the folds. Cut straight down with ihe gouge, using a mallet to drive the cutting edge into the wood. The eouge I am Pin do 7: Remove wood with horizontal cuts. using here is a IOmm no. 5 gouge t Photo <>l. 1 also used a 12mm no. I gouge. M ike llie sides of the cul as vertical as possible. Ilien. make horizontal cuts in from ihe end with an 8mm no. 3 gouge to remove the waste wood (Pholo 7). Don't try to remove all the wood in one step, take the cut down in several stages. Leave '/if> in. of the background wood intact at this point. This is important because the final step in shaping these folds w ill be to undercut them slightly. If you have driven the gouge all the way down to the background surface, you will leave cut marks which will show when the carving is finished. After the end folds are set in. sketch in the inner folds free hand (Photo 81. This will help you picture where the folds will fall in the wood. Now. using a 20mm no. ? gouge, bevel down from the inner edge of the The Woodworker'?. Journal Special Techniques Continued |

|||||||||||||||||||||||||||||||||