Woodworker's Journal 1985-9-6, страница 32

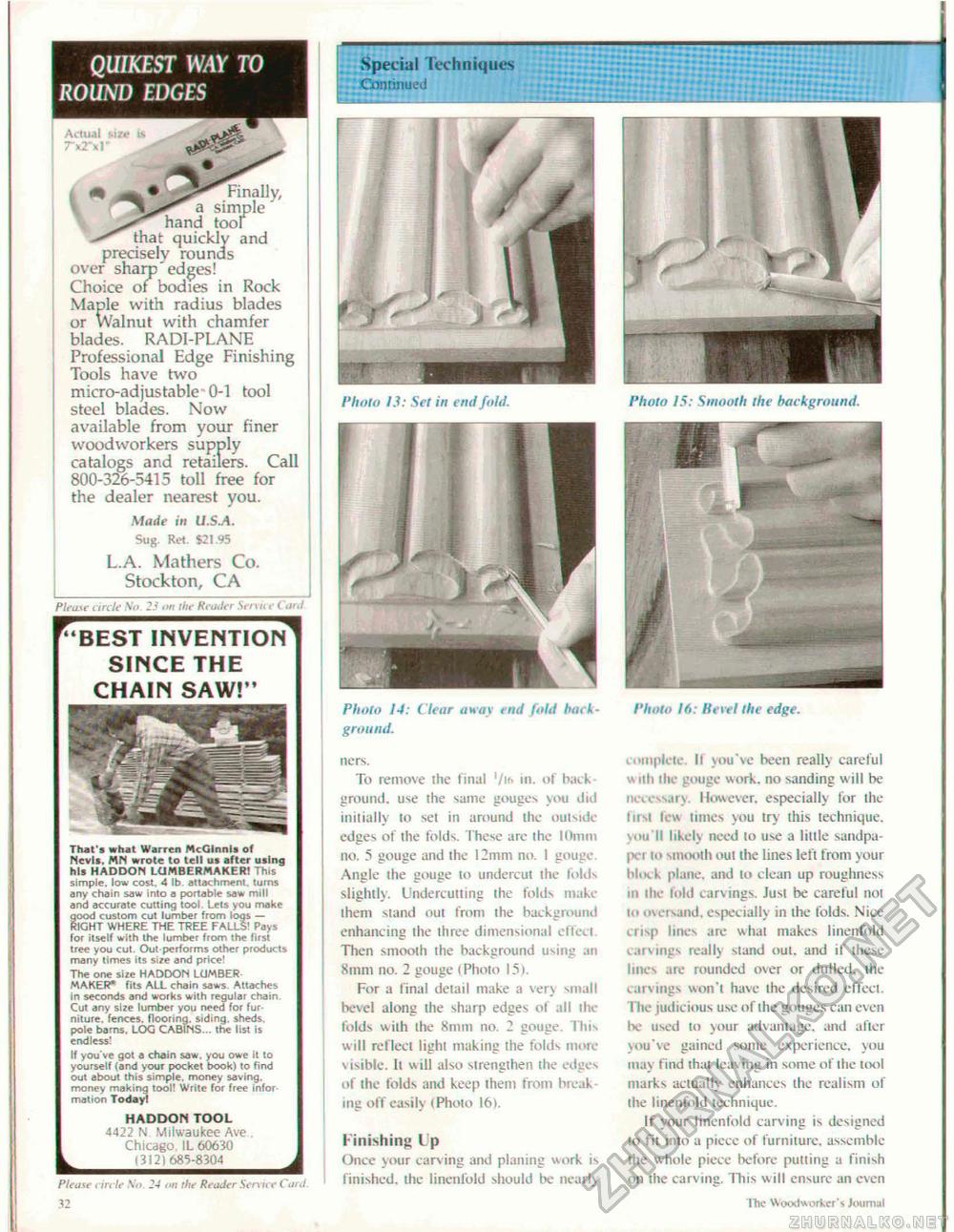

QUIKEST WAY TO ROUND EDGES Actual sine is 7-*r*r ^ t Finally, a simple hand toof that quickly and precisely rounds over sharp edges! Choice of bodies in Rock Maple with radius blades or Walnut with chamfer blades. RAD1-PLANE Professional Edge Finishing Tools have two micro-adjustable" 0-1 tool steel blades. Now available from your finer woodworkers supply catalogs and retailers. Call 800-326-5415 toll free for the dealer nearest you. Made in U.S.A. Sug. Ret. $21.95 L.A. Mathers Co. Stockton, CA Phase circle No. 23 on liic Ranter Seisii r ( aril "BEST INVENTION SINCE THE CHAIN SAW!" Tlut's what Warren McGlnnii of Nevis. MN wrote to tell us after using his HADDON LCJMBERMAKER! This simple, low cost. 4 lb. attachment. turns any chain saw into a portable saw mill and accurate cutting tool Lets you make good custom cut lumber from logs — RIGHT WHERE THE TREE FALLS! Pays for ilself with ihe lumber from the first tree you cut. Out performs other products many times its siie and price! The one site HADDON LUMBER-MAKER" fits ALL chain saws Attaches in seconds and works with regulai chain. Cut any size lumber you need for furniture. fences, flooring, siding. sheds, pole bams. LOG CABINS... the list is endless! If you've got a chain saw. you owe it to yourself (and your pocket book) to find out about this simple, money saving, money making tool! Write for free infor mation Today! HADDON TOOL 4422 M Milwaukee Ave . Chicago. 1L 60630 (3121 685-8304 Special Techniques Continued Photo 13: Set in end fold. Photo 15: Smooth the background. Please circle No. 24 on the Reader Senil e Card 32 Photo 14: Clear away end fold back -ground. ners. To remove the final '/li in. of back ground, use the same gouges you did initially to set in around the outside edges of the folds. These arc the 10mm no. 5 gouge and the 12mm no. I gouge. Angle the gouge to undercut the folds slightly. Undercutting ihe folds make ihem stand out from the background enhancing the three dimensional eficii Then smooth the background using an 8tnm no. 2 gouge (Photo 15). For a final deiail make a very small bevel along the sharp edges of all ihe folds with the 8mm no. 2 gouge. This will reflect light making the folds more visible. It will also strengthen the edges of ihe folds and keep them from breaking off easily (Photo 16). Finishing Lp Once your carving and planing work is finished, the linenfold should be nearly Photo 16: Bevel the edge. oonplcic. II you've been really careful wuh ihe gouge work, no sanding will be necessary. However, especially for the first tew times you try this technique, \ou II likely need lo use a liltle sandpa-jvr lo smooth oui the lines left from your block plane, and lo clean up roughness in the fold carvings. Jusl be careful not lo overs and. especial!) in the folds. Nice crisp lines are whai makes linenfold carvings reallv stand out. and if these tines are rounded over or dulled, the carvings won't have the desired effect. The judicious use of ihe gouges can even be used to your advantage, and after you've gained some experience, you may find that leav ing in some of the tool marks aciuallv enhances the realism of ihe linenfold technique. If your linenfold carving is designed to fit into a piccc of furniture, assemble the whole piece before putting a finish on the carving. This will ensure an even 32 TIil- Woodworker's Journal |