Woodworker's Journal 1985-9-6, страница 57

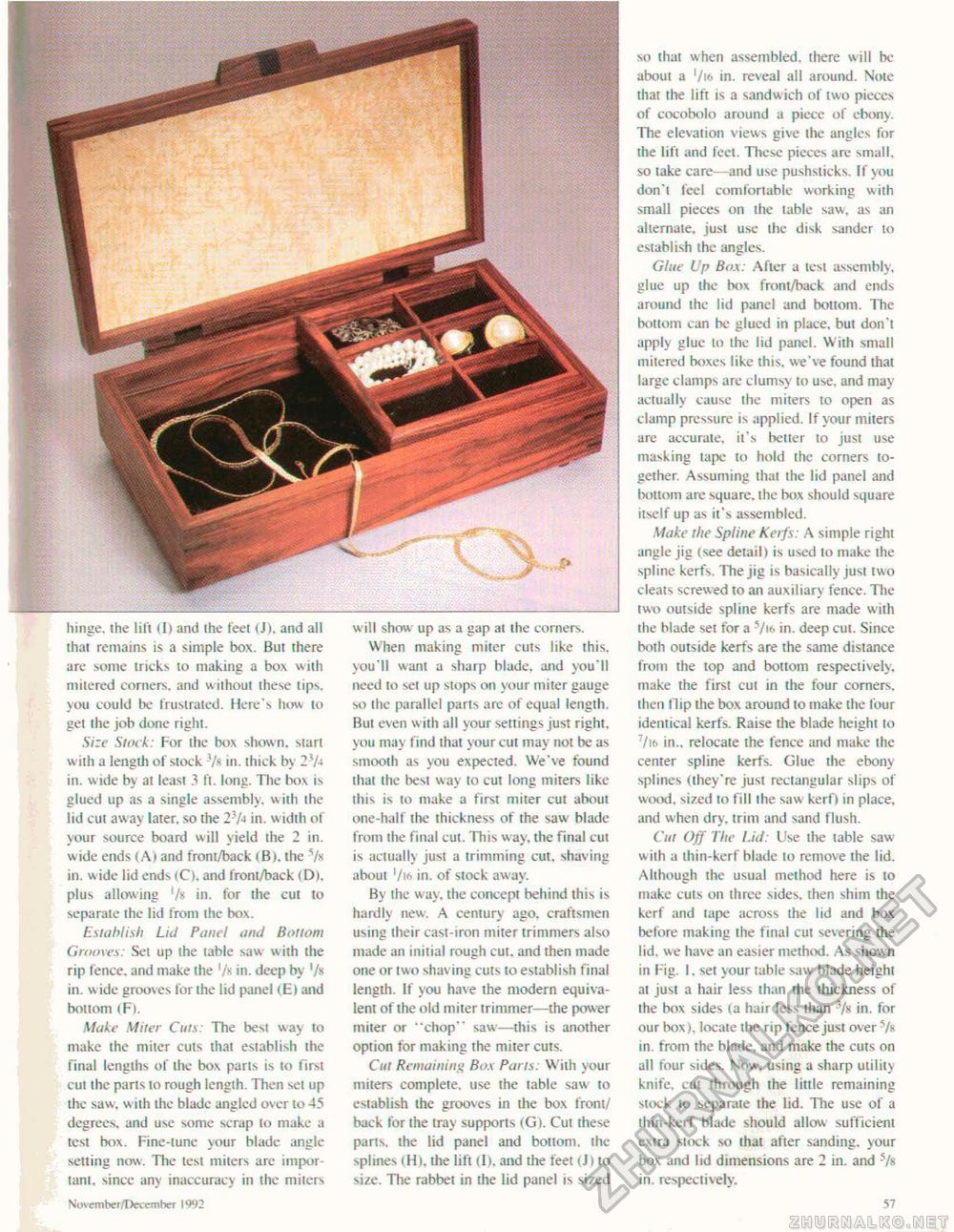

hinge, the lilt (I) and the feet (J). and all that remains is a simple box. But there are some tricks to making a box with milered corners, and without these tips, you could be frustrated. Here's how to get the job done right. Size Slock: For the box shown, start w ith a length of stock -/«in. thick by 2 V* in. w ide by at least 3 ft. long. The box is glued up as a single assembly, w ith the lid cut aw ay later, so the 2}H in. w idih of your source board will yield the 2 in. wide ends (A) and front/back <B|. the Vs in. w ide lid ends (C), and front/back (D), plus allowing '/« in. for the cut to separate the lid from the box. Establish Lid PaneI and Bottom Grooves: Sel up the table saw w ith the rip fence, and make the in. deep by '/» in. wide grooves for the lid panel <E) and bottom (F). Make Miter Cuts: The best way to make the miter cuts that establish the final lengths of the box parts is to first cut the parts to rough length. Then set up the saw. with the blade angled over to 45 degrees, and use some scrap to make a test box. Fine-tune your blade angle setting now. The lest miters are important. since any inaccuracy in the miters Nov ember/December 1992 will show up as a gap at the corners. When making miter cuts like this, youll want a sharp blade, and you'll need to set up stops on your miter gauge so the parallel parts are of equal length. Rut even with all your settings just right, you may find that your cut may not be as smooth as you expected. We've found that the best way to cut long miters like this is to make a first miter cut about one-half ihe thickness of the saw blade from the final cut. This way, the final cut is actually just a trimming cut. shaving about in. of stock away. By the w ay. the concept behind this is hardly new. A century ago. craftsmen using their cast-iron miter trimmers also made an initial rough cut. and then made one or two shaving cuts to establish final lenglh. If you have the modern equivalent of the old miter trimmer—the power miter or "chop" saw—this is another option for making the miter cuts. Cut Remaining Box Parts: With your miters complete, use the table saw to establish the grooves in the box front/ back for (he tray supports (G). Cut these parts, the lid panel and bottom, the splines ill).ihe lift (1).and die feet (Jito size. The rabbet in the lid panel is sized so that when assembled, there will be about a '/i& in. reveal all around. Note that the lift is a sandwich of two pieces of cocobolo around a piece of ebony. The elevation views give the angles for the lift and feel. These pieces are small, so take care—and use pushsticks. If you don't feel comfortable working with small pieces on the table saw, as an alternate, just use ihe disk sander to establish the angles. Glue Up Box: After a test assembly, glue up ihe box front/back and ends around the lid panel and bottom. The bottom can be glued in place, but don't apply glue lo the lid panel. With small mitered boxes like this, we've found that large clamps arc clumsy to use, and may actually cause the miters to open as clamp pressure is applied. If your miters are accurate, it's better to just use masking tape to hold the corners together. Assuming that the lid panel and bottom are square, the box should square itself up as it's assembled. Make the Spline Keifs: A simple right angle jig (see detail) is used to make the spline kerfs. The jig is basically just two cleats screw ed to an auxiliary fence. The two outside spline kerfs are made with the blade set for a s/i6 in. deep cut. Since both outside kerfs are the same distance from the top and bottom respectively, make the first cut in the four corners, then flip the box around to make the four identical kerfs. Raise the blade height to 7/i& in., relocate the fence and make the center spline kerfs. Glue the ebony splines (they're just rectangular slips of wood, sized to fill the saw kerf) in place, and when dry. trim and sand flush. Cut Off The Lid: Use the table saw with a shin-kcrf blade to remove the lid. Although the usual method here is to make cuts on three sides, then shim the kerf and tape across the lid and box before making the final cut severing the lid. we have an easier method. As show n in Fig. 1. sel your tahle saw blade height at just a hair less than the thickness of the box sides (a hair less than */s in. for our box), locate the rip fence just over 7* in. from the blade, and make the cuts on all four sides. Now, using a sharp utility knife, cut through the little remaining stock to separate the lid. The use of a thin-kerf blade should allow sufficient extra siock so that after sanding, your box and lid dimensions are 2 in. and 5/s in. respectively. 57 |