Woodworker's Journal 1992-16-5, страница 21

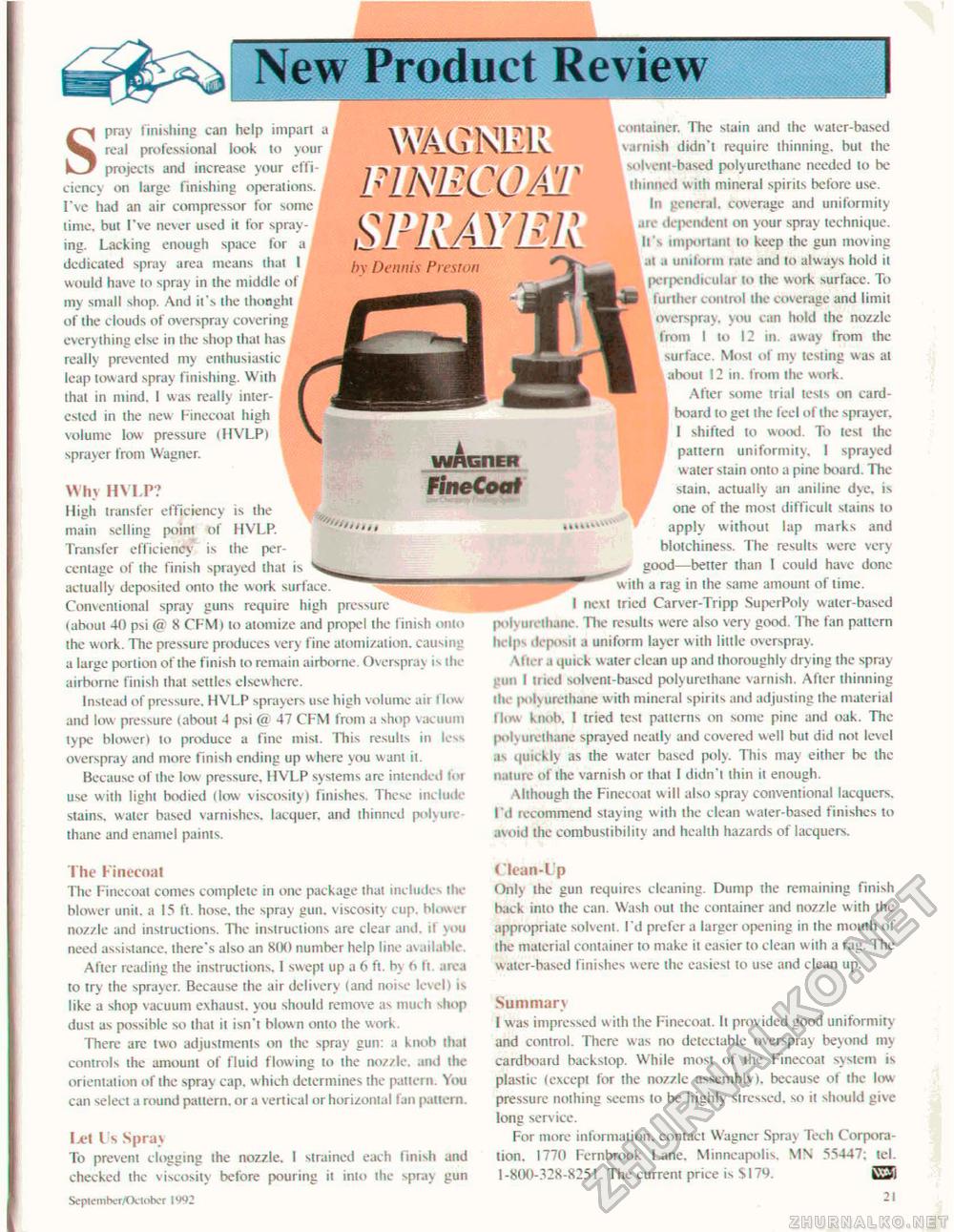

Spray finishing can help impart a real professional look to your | projects and increase your efficiency on large finishing operations. : I've had an air compressor for some Ji time, but I've never used it for spray- I ing. Lacking enough space for a dedicated spray area means that 1 would have to spray in the middle of .■'= my small shop. And it's the thought of the clouds of ovcrspray covering j| everything else in the shop that has really prevented my enthusiastic leap toward spray finishing. With that in mind. 1 was really inter- | ested in the new Finecoat high volume low pressure (HVLP) sprayer from Wagner. WAGNER FLNECOAV SPliAl'ELi by Dennis Preston WAGRER FineCoat "hi Why HVLP? High transfer efficiency is the main selling point of HVLP. Transfer efficiency is the percentage of the finish sprayed that is actually deposited onto the work surface. Conventional spray guns require high pressure (about 40 psi @ 8 CFM) lo atomize and propel the finish onto the work. The pressure produces very l ine atomization, causing a large portion of the finish lo remain airborne. Ovcrspray is the airborne finish that settles elsewhere. Instead of pressure, HVLP sprayers use high volume air How and low pressure (about 4 psi @ 47 CFM from a shop vacuum type blower) to produce a fine mist. This results in less overspray and more finish ending up where you want it. Because of the low pressure. HVLP systems are intended lot use with light bodied (low viscosity) finishes. These include stains, water based varnishes, lacquer, and thinned polvurc-thane and enamel paints. The Finecoat The Finecoat comes complete in one package that includes the blower unit, a 15 ft. hose, the spray gun. viscositv cup, blower nozzle and instructions. The instructions are clear and. if you need assistance, there's also an 800 number help line available. After reading the instructions. I swept up a 6 ft. b\ b ft. area to try the sprayer. Because the air delivery (and noise level) is like a shop vacuum exhaust, you should remove as much shop dust as possible so that it isn't blown onto the work. There arc two adjustments on the spray gun: a knob that controls the amount of fluid flowing to the nozzle, and the orientation of the spray cap. w hich determines the pattern. You can select a round pattern, or a vertical or horizontal fan pattern. Ijft Us Spray To prevent clogging the nozzle. I strained each finish and checked the viscosity before pouring it into the spray gun September/October 1992 container. The stain and the water-based varnish didn't require thinning, but the solvent-based polyurcihane needed to be I thinned with mineral spirits before use. In general, coverage and uniformity are dependent on your spray technique. It's important to keep the gun moving at a uniform rate and to always hold it perpendicular to the work surface. To further control tile coverage and limit overspray. you can hold the nozzle from I to 12 in. away from the surface. Most of my testing w as at |. about 12 in. from the work. After some trial tests on cardboard to get the feel of the sprayer, I shifted to wood. To lest the pattern uniformity, I sprayed water stain onto a pine board. The stain, actually an aniline dye. is one of the most difficult stains lo apply without lap marks and blotchiness. The results were very good—better than I could have done "" with a rag in the same amount of time. I next tried Carver-Tripp SuperPoly water-based polyurethane. The results were also very good. The fan pattern helps deposii a uniform layer with little overspray. Aftei a quick water clean up and thoroughly drying the spray gun I tried solvent-based polyurethane varnish. After thinning tin- polvurethane with mineral spirils and adjusting the material flow knob. 1 tried test patterns on some pine and oak. The |H>lyurelhane sprayed neatly and covered well but did not level as quickly as the water based poly. This may either be the nature of the varnish or that I didn't thin it enough. Although the Finecoat w ill also spray conventional lacqucrs. I'd recommend staying with the clean water-based finishes to avoid the combustibility and health hazards of lacquers. Clean-L'p Only the gun requires cleaning. Dump the remaining finish back into the can. Wash oul the container and nozzle with inappropriate solvent. I'd prefer a larger opening in the mouth of the material container to make it easier to clean with a rag. The water-based finishes were the easiest to use and clean up. Summary [ was impressed with the Finecoat. It provided good uniformity and control. There was no detectable overspray beyond my cardboard backstop. While most of the Finecoat system is plastic (except for the nozzle assembly), because of the low pressure nothing seems to be highly stressed, so it should give long service. For more information, contact Wagner Spray Tech Corporation. 1770 Fcrnbrook Lane. Minneapolis, MN 55447; tel. 1-800-328-8251. The current price is S174. O 21 |