Woodworker's Journal 1992-16-5, страница 20

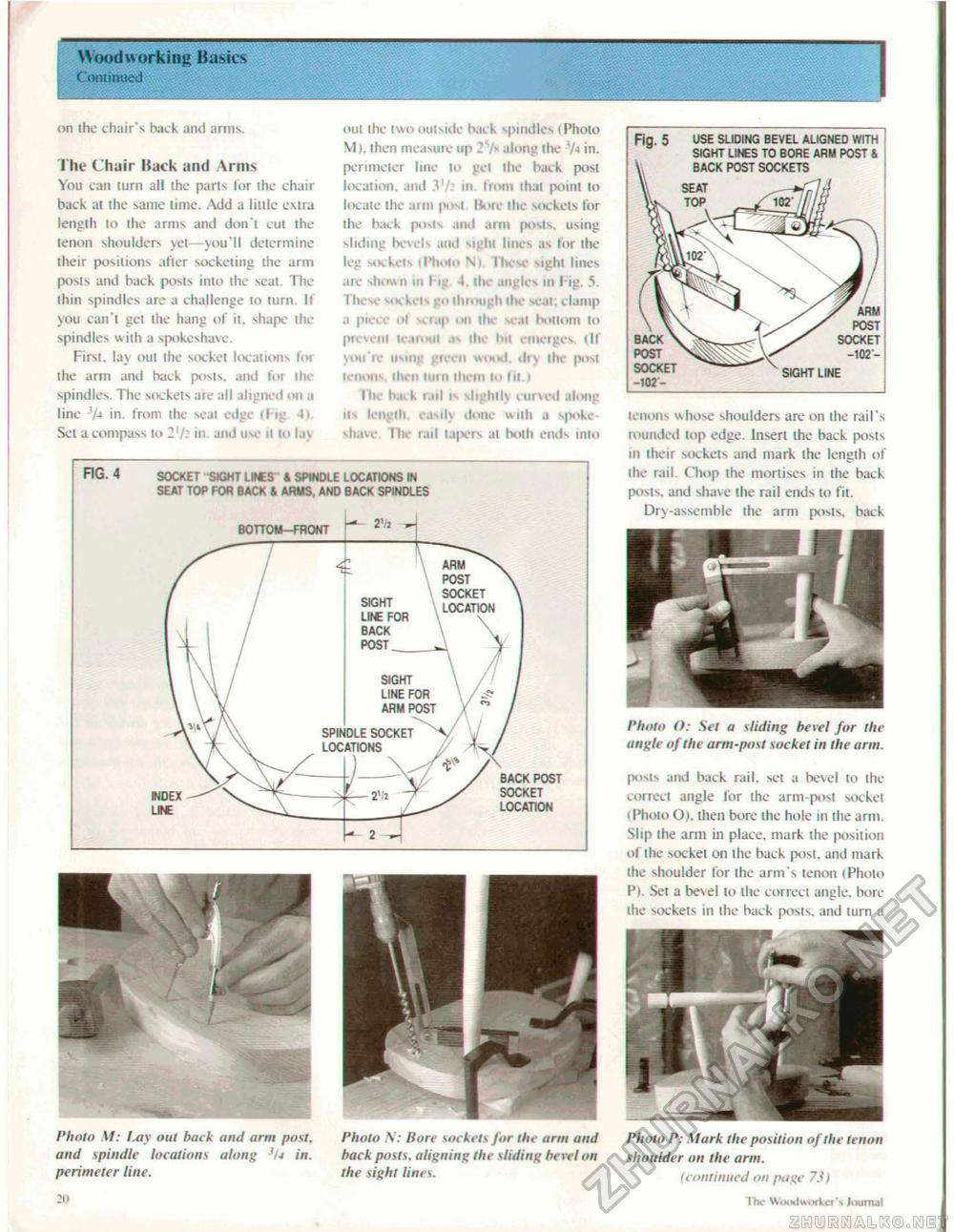

Woodworking Basics Continued on the chair's hack and arms. The Chair Hack and Arms You can turn all the parts tor the chair back at the same lime. Add a little extra length to the arms and don't cut the tenon shoulders yet—you'll determine their positions alter socketing the arm posts and back posts into the seal. The thin spindles are a challenge to turn. It you can't get the hang of it. shape the spindles with a spokeshave. First, lay out the socket locations for the arm and hack posts, and for the spindles. The sockets are all aligned •»»a line lA in. from the seal edge (ltg t| Set a compass 10 2'/." in. and Use it to lay out the iwo ouisidc bav k spindles i Photo VI), then measure up 2 along the '/-i in. perimeter line lo get the back post location, and V/: m from that point to locate the arm post Bore Ihe sockets for the back posts ami arm |>os|s. using sliding bevels and sight lines as for the leg sockets (Photo N| these sight lines are shown in I >y J, tin- angles in Fig. 5. These siv keis go through the scat, clamp a piecc of snap on the seat hoilom to prevent lcafoul ,i\ Ihe bil emerges, (If you're using green wood, dry the posi tenons, ihen turn ihem to til.) the bail rail is slighily curved along its length, easily done with a s|>oke-shavc lite fail laj>ers at hoih ends into FIG. 4 SOCKET SIGHT L»€S & SPINDLE LOCATIONS IN SEAT TOP FOR BACK & ARMS, AND BACK SPINDLES Photo M: Lay out hack and arm post, and spindle locutions along 3U in. perimeter line. 20 Photo .V; Bore sockets for the arm and hack posts, aligning the sliding bevel on the sight lines. tenons whose shoulders are on the rail's rounded top edge. Insert the back posts in their sockets and mark the length of the rail. Chop the mortises in the back posts, and shave the rail ends to fit. Dry-assemble the arm posts, back Photo O: Set a sliding bevel for the angle of the arm-post socket in the arm. posts and back rail, set a bevel to the correct angle for the arm-post socket i Photo O). ihen bore the hole in the arm. Slip the arm in place, mark the position of the socket on the back post, and mark the shoulder for the arm's tenon (Photo Pi. Set a be\e! to the correct angle, bore the sockets in the back posts, and turn a Photo P: Mark the position of the tenon shoulder on the arm. {continued on page 73) The Woodworker's Journal |