Woodworker's Journal 1992-16-5, страница 26

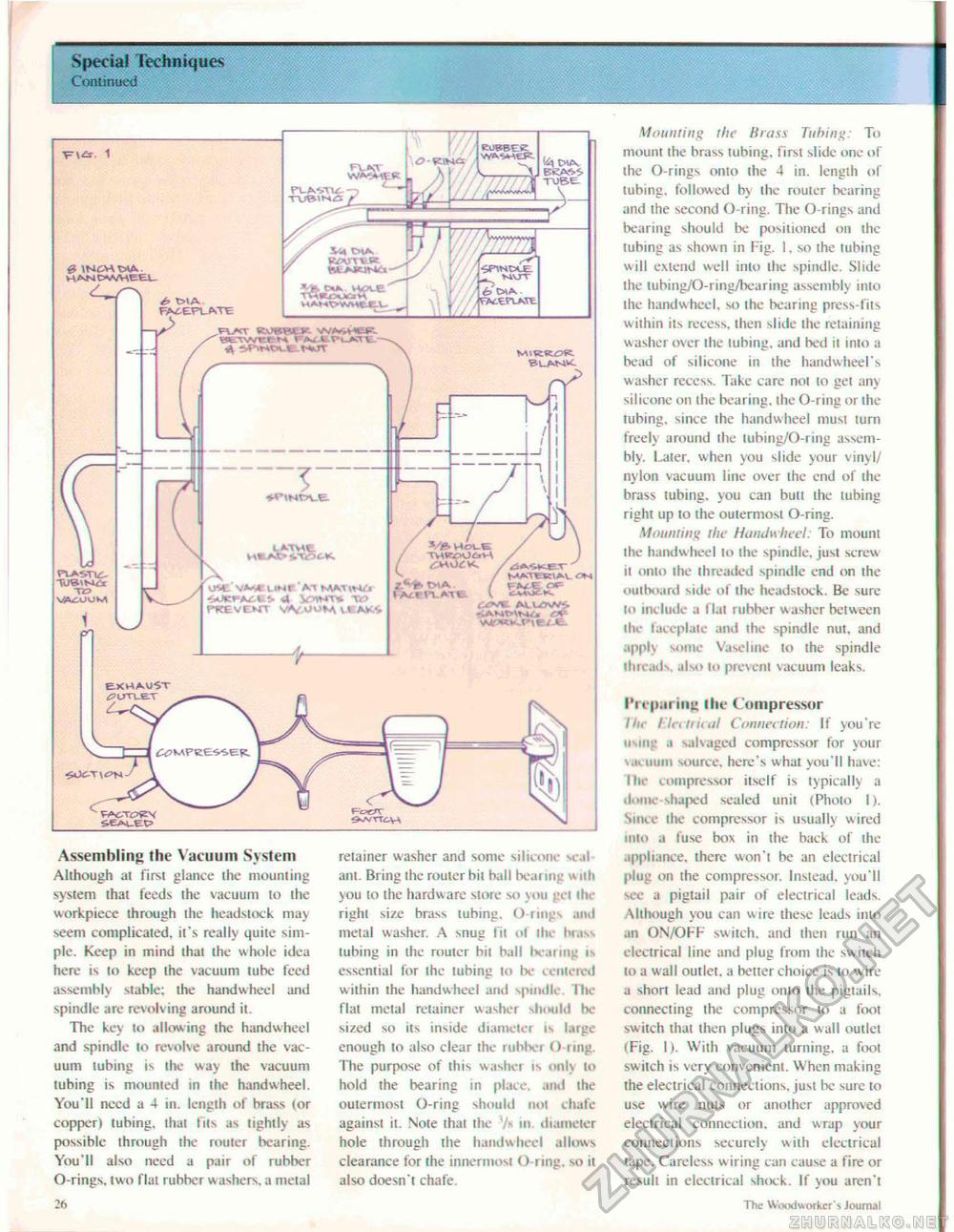

Special Techniques Continued fv^ 1 0 IM£-V\ WA £> TMA FACEPLATE Mt-SWItN FMXVU.1T •A SPWWUfc. MtJT T UlVtt 0"jt v*-sr Liwr Art MM,M/i ■frOWA^ L S Jk ifflMT* TK> PREVENT V^.OUH H A-WV ^■swer (^VE Al USW-e. Assembling the Vacuum System Although at first glance the mounting system that feeds the vacuum to the workpiece through the head slock may seem complicated, it's really quite simple. Keep in mind that the whole idea here is to keep the vacuum tube feed assembly stable: the hand wheel and spindle are revolving around it. The key to allowing the handwheel and spindle lo revolve around the vacuum tubing is ihe way the vacuum tubing is mounted in ihe handwheel. You'll need a 4 in. length of brass (or copper) (ubing, that fits as tightly as possible through the router bearing. You'll also need a pair of rubber O-rings, two flat rubber w ashers. a metal 26 retainer washer and some silicone seal ant. Bring the router bit ball bearing wilh you to the hardware store so yon gel the right size brass tubing. O-rings and metal washer. A snug fit ol the brass luhing in the router hil ball bearing is essential for the tubing to be centered w ithin the handwheel and spindle lite flat metal retainer washer should be sized so its inside diameter is large enough to also clear the rubber O-ring. The purpose of this washer is only lo hold the bearing in place, and the outermost O-ring should not chafe against it. Note thai the '/» in. diameter hole through the handwheel allows clearance tor the innermost O ring. so it also doesn't chafe. Mounting the Brass Tubing: To mount the brass tubing, first slide one of the O-rings onto the 4 in. length of tubing, followed by the router bearing and the second O-ring. The O-rings and bearing should be positioned on the tubing as shown in Fig. 1. so the tubing will extend well into the spindle. Slide the tubing/O-ring/bearing assembly into the handwheel, so the bearing press-fits within its recess, then slide the retaining washer over the tubing, and bed it into a bead of silicone in the hand wheel's washer recess. Take care not to get any silicone on the bearing, the O-ring or the tubing, since the handwheel must turn freely around the tubing/O-ring assembly. I^ater. when you slide your vinyl/ nylon vacuum line over the end of (he brass tubing, you can bun the tubing right up lo the outermost O-ring. Mounting the Handwheel To mount the handwheel lo the spindle, just screw it onto the threaded spindle end on the outboard side of the headstock. Be sure to include a Hal rubber washer between the faceplate and the spindle nut. and apply some Vaseline to the spindle threads, also to prevent vacuum leaks, I'd (mi iii); Ihe Compressor III- flectrual Connection: If you're Using a salvaged compressor for your *.ii iium source, here's what you'll have: Ihe compressor itself is typically a dome-shaped sealed unit (Pholo 1). Since ihe compressor is usually wired iiiio a fuse box in the back of the appliance, there won't be an electrical plug on the compressor. Instead, you'll see a pigtail pair of electrical leads. Although you can wire these leads into an ON/OFF switch, and then run an electrical line and plug from the switch to a wall outlet, a better choice is to w ire a short lead and plug onto the pigtails, connecting the compressor to a foot switch that then plugs into a wall outlet (Fig. I). With vacuum turning, a foot swiich is very convenient. When making the electrical connections, just be sure to use wire nuts or another approved electrical connection, and wrap your connections securely with electrical tape. Careless wiring can cause a fire or result in electrical shock. If you aren't The Woodworker's Journal |