Woodworker's Journal 1992-16-5, страница 28

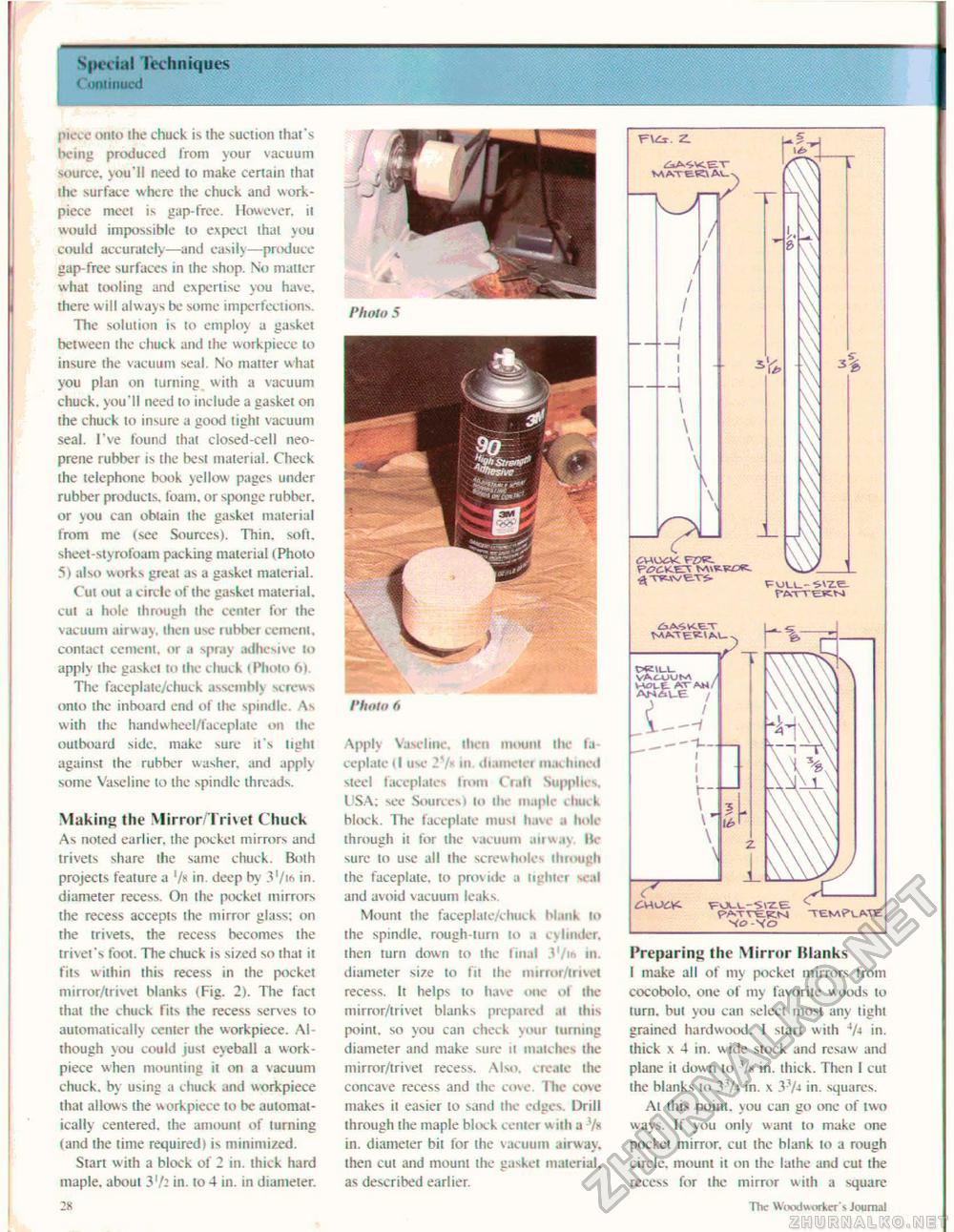

piece onlo ihe chuck is the suction that's being produced from your vacuum source, you'll need to make certain that the surface where the chuck and work-piece meet is gap-free. However, it would impossible to expect that you could accurately—and easily—produce gap-free surfaces in the shop. No matter what tooling and expertise you have, there will always be some imperfections. The solution is to employ a gasket between the chuck and the workpiece to insure the vacuum seal. No matter what you plan on turning with a vacuum chuck, you'll need to include a gasket on the chuck to insure a good tight vacuum seal. I've found that closed-cell neo-prene rubber is the best material. Check the telephone book yellow pages under rubber products, foam, or sponge rubber, or >ou can obtain the gasket material from me (see Sources). Thin. soft, sheet-slyrofoam packing material (Photo 5) also works great as a gasket material. Cut out a circle of the gasket material, cut a hole through the center for the vacuum airway, then use rubber cement, contact cement, or .1 spray adhesive to apply the gasket to the chuck (Photo 6) The faceplate/chuck assembly screws onto the inboard end of the spindle. \s with the handwheel/faceplate on the outboard side, make sure it's tight against the rubber washer, and apply some Vaseline lo the spindle threads. Making the Mirror/Trivet Chuck As noted earlier, the pocket mirrors and trivets share the same chuck. Both projects feature a '/* in. deep by V/ta in. diameter recess. On the pocket mirrors the recess accepts the mirror glass; on the trivets, the recess becomes the trivet's foot. The chuck is si7ed so thai it fits within this recess in the pocket mirror/trivet blanks (Fig. 2). The fact thai the chuck Fits the recess serves to automatically center the workpiece. Although you could just eyeball a work-piece when mounting it on a vacuum chuck, by using a chuck and workpiece that allows the workpiece to be automatically centered, the amount of turning (and the time required) is minimized. Start with a block of 2 in. thick hard maple, about 37? in. to 4 in. in diameter. 28 Photo 5 Photo 6 Apply Vaseline, then mount the faceplate il use 27* 111. diameter machined steel faceplates from Craft Supplies. USA: see Sources 1 10 ihe maple t huik block. The faceplate must have a hole through it for the vacuum airwav Ik-sure to use all ihe screw holes tluough Ihe faceplate, to provide a lighter seal and avoid vacuum leaks Mount the faceplate/chuck blank 10 the spindle, rough-turn to a cylinder, ihen turn down to the final 37'& 111. diameter si?e to fit ihe mirror/trivet recess. It helps to have one ol Ihe mirror/trivet blanks prepared .11 ihis point, so you can check your turning diameter and make sure it matches the mirror/trivet recess. Also, create the concave recess and the cove. The cove makes it easier to sand the edges. Drill through the maple block center w 11I1 a 7* in. diameter bit for the vacuum airway, then cut and mount the gaskei material, as described earlier. FVdi z. ^Ker material ----1 -I / viic-T FULL-Wie. FesT-re.wiNi txeii-L. VAtWUM HOUt AT AW / Anaue / / i i ---1— I I I t-\ pATTCKtvi TEKAv'VA.Te VO-VO Preparing the Mirror Blanks I make all of my pocket mirrors from cocobolo, one of my favorite woods to turn, but you can select most any tight grained hardwood. I start with XU in. thick x 4 in, wide slock and resaw and plane it down to 7a in. thick. Then I cut the blanks lo 3JA in. x .V/4 in. squares. At this point, you can go one of two ways. If you only want to make one pocket mirror, cut the blank to a rough circle, mount il on the lathe and cut the recess for the mirror with a square 28 The Woodworker's Journal |