Woodworker's Journal 1992-16-5, страница 31

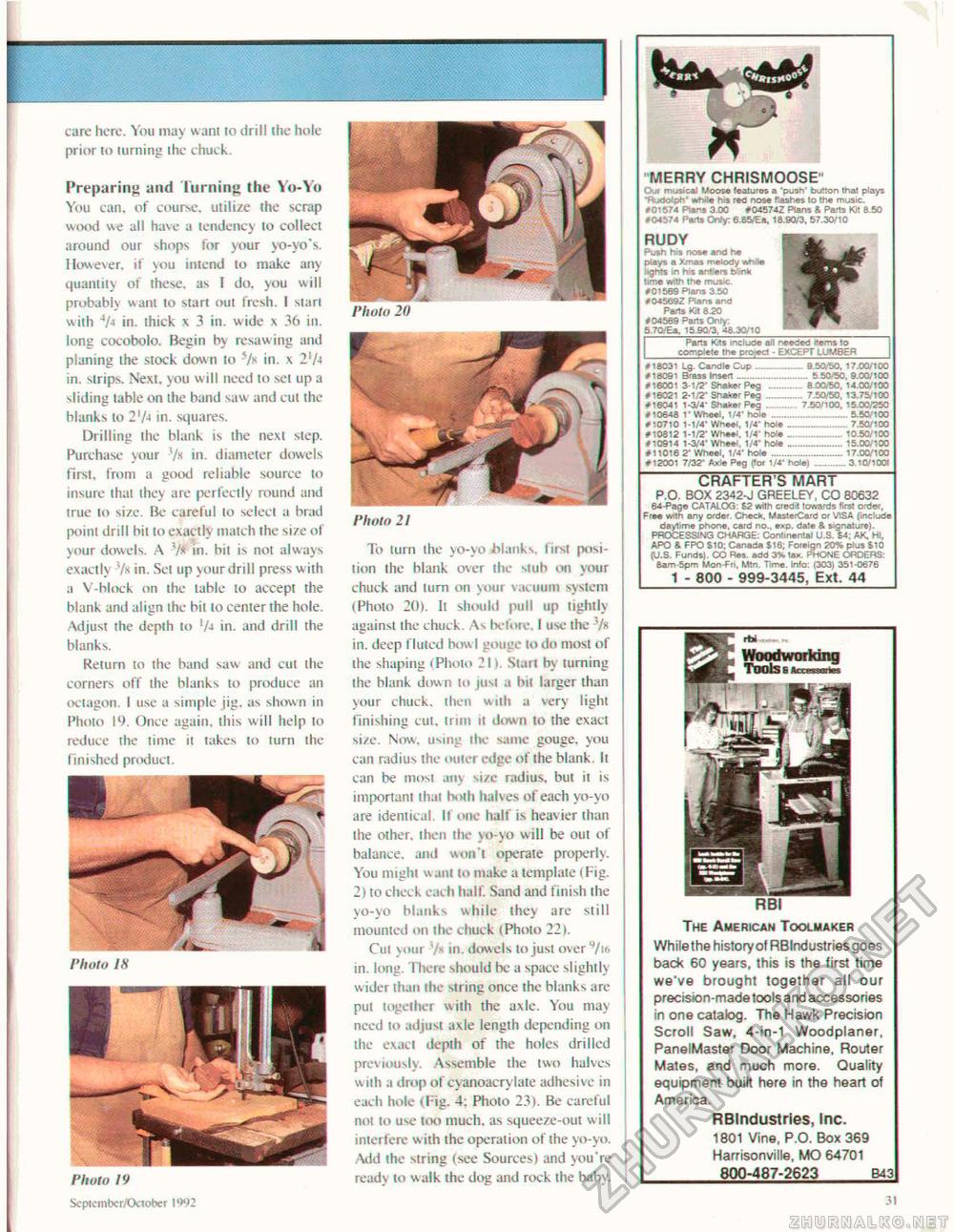

care here. You may warn to drill the hole prior to turning the chuck. Preparing and Turning the Yo-Yo You can, of course, utilize the scrap wood we all have a tendency to collect around our shops for your yo-yo's. However, if you intend to make any quantity of these, as I do, you will probably want to stan out fresh. I start with 4/j in. thick x 3 in. wide x 36 in. long cocobolo. Begin by resawing and planing the stock down to 5/x in. x 2'/-» in. sirips. Next, you will need to set up a sliding table on the band saw and cut the blanks to 2'/-> in. squares. Drilling the blank is the next step. Purchase your 7s in. diameter dowels first, from a good reliable source to insure that they are perfectly round and true to size. Be careful to select a brad point drill bit to exactly match the size of your dowels. A V! in. bit is not always exactly 7x in. Set up your drill press w iih ;i V-block on the table to accept the blank and align the bit to center the hole. Adjust the depth to '/4 in. and drill the blanks. Return to the band saw and cut the corners off the blanks to produce an octagon. I use a simple jig. as shown in Photo 19. Once again, this will help to reduce the time it takes to turn the finished product. 1'hoto IS Photo 19 Scptember/Oetober 1992 Photo 21 To turn the vo-vo blanks, first position the blank over the stub on your chuck and turn on your vacuum sy stem (Photo 2<)>. It should pull up tightly against the chuck. As before. I use the 7« in. deep fluted bow l gouge to do most of the shaping (Photo 2 I i Start by turning the blank down to jtisi a bit larger than your chuck, then with a very light finishing cut. I rim it down to the exact si/e. Now, using ihe same gouge, you can radius the outer edge of the blank, it can be most any size radius, but it is important that both halves of each yo-yo are identical. It one half is heavier than the other, then the yo-yo will be out of balance, and won't operate properly. You might w ant to make a template (Fig. 2) to check each half. Sand and finish the yo-yo blanks white they are still mounted on the chuck (Photo 22). Cut your 7h in. dowels to just over 4/if> in. long. I here should he a space slightly wider than the string once the blanks are put together with the axle. You may need to adjust axle length depending on the exact depth of the holes drilled previously. Assemble the two halves w ith a drop of cyanoacrylate adhesive in each hole (l:ig. 4: Photo 23). Be careful not to use too much, as squeeze-out w ill interfere w ith the operation of the yo-yo. Add the string (see Sources) and you're ready to walk the don and rock the baby. * MERRY CHRISMOOSE" Out musical Moose features a 'push' button that plays ftmotph" »rMe ha fed nose flashes 10 the music. #01374 Piars 3.00 #045742 Plans & Parts Kit 8.50 #04374 Pull Only: 6.85/Ea, 16.90/3. 57.30/10 RUDY Push his nose and he plays a Xmes melody lights in hts antlers ttink time with the muue. #01569 Plans 3,50 #04569Z Plans and Parts KH 8.20 #04569 Parts Only: 570/Ea. 15.90.-3. 46.30/10 Perts Kns include BiL reeded items to complete the pro»ed ■ EXCEPT LWBtS #18031 #18051 #16001 #16021 #teo4i #10648 #10710 #10812 #10914 #1t0l6 #12001 Lg. Candle Cup Brass Insert____________ 3-1/2' Shatter Peg ____ 2-1/2' Shaker Peg______ 1-3/4' Shaker Peg........ 11 wheel. 1/4' hole ...... 1-1/4' Wheel, 1/4' hole 1-1/2' WHee=. 1/4' hole 1-3/4' Wheel, 1/4' hole 2' Wheel, 1/4' hole ...... 7/32" Axle Peg (Tor 1/4' ___B.50/50, 17.00/100 ....... 5.50/50, 9.00/100 ___ 8.00(50. 14.00/100 ______ 7.50/50, 13.75,'100 7.50/100. 15.00/250 ________________5.50/100 ___________7.50/100 ....................10.50/100 ........_.......... 15.00/100 .................17JXV100 hole)_____310/1001 CRAFTER'S MART P.O. BOX 2342-J GREELEY, CO 80532 64-Page CATALOG: £2 wiih credit towards first order, Free with any order. Check, MasterCard or VISA (include daytime phone, card no,, exp. date & signature). PROCESSING CHARGE: Continental U.S. S4; AX. HI, APC « FPO S10, Canada S16; Foreign 2C% plus SiO (U.S. Funds). CO Res. add 3% lax PHONE ORDERS: ftam-5pm Mon-Frt, Mtn. Time. Into: (303) 351-0676 1 - 800 - 999-3445, Ext. 44 Woodworking RBI The American Toolmaker While the history of RBIndustriesgoes back 60 years, this is the first time we've brought together all our precisio n-m ade too Is and accessories in one catalog. The Hawk Precision Scroll Saw, 4-in-1 Woodplaner, PanelMaster Door Machine, Router Mates, and much more. Quality equipment built here in the heart of America. RBlndustries, Inc. 1801 Vine, P.O. Box 369 Hamsonville, MO 64701 _800-487-2623 B43 31 |