Woodworker's Journal 1992-16-6, страница 65

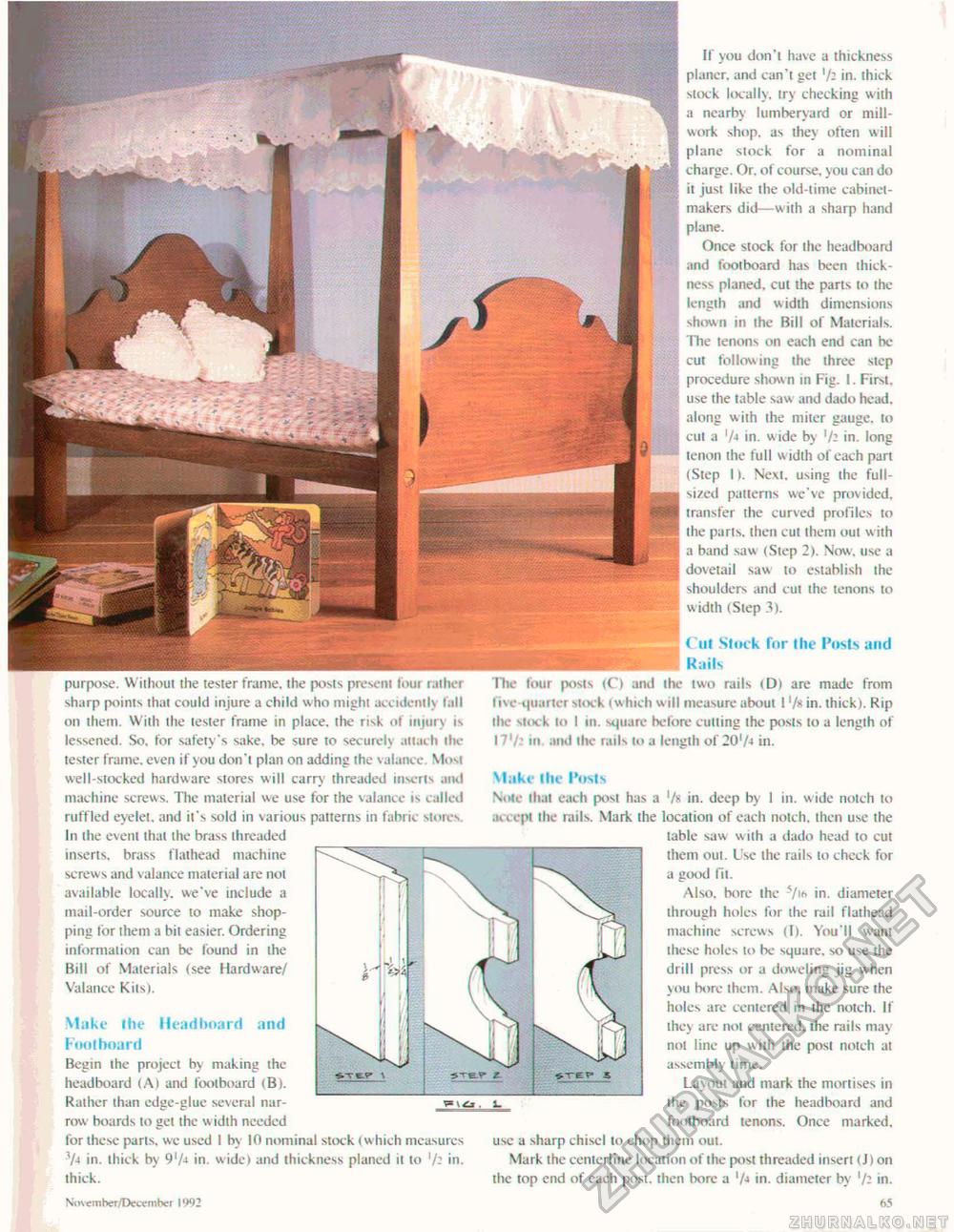

purpose. Without the tester frame, the posts present four rather sharp points that could injure a child who might accidently fall on them. With the tester frame in place, the risk of injury is lessened. So, for safety's sake, be sure to securely attach the tester frame, even if you don'i plan on adding the valance. Most well-stocked hardware stores will carry threaded inserts and machine screws. The material we use for the valance is called ruffled eyelet, and it's sold in various patterns in fabric stores. In the event that the brass threaded inserts, brass flathead machine screws and valance material are not available locally, we've include a mail-order source to make shopping for them a bit easier. Ordering information can be found in the Bill of Materials (see Hardware/ Valance Kits). Make Ihe Headboard and Footboard Begin the project by making the headboard (Al and footboard iB). Ralher than edge-glue several narrow boards to get the width needed for these parts, we used I by 10 nominal stock (w hich measures 3/4 in. thick by 9'/4 in. wide) and thickness planed it to '/- in. thick. Nov ember/December 1992 If you don'i have a thickness planer, and can't get lh in. thick slock locally. try checking with a nearby lumberyard or mill-work shop, as they often will plane slock for a nominal charge. Or, of course, you can do it just like the old-time cabinetmakers did—wilh a sharp hand plane. Once stock for the headboard and footboard has been ihick-ness planed, cut the parts to ihe length and widih dimensions shown in ihe Bill of Materials. The tenons on each end can be cut following the three step procedure shown in Fig. I. First, use the table saw and dado head, along with the miter gauge, to cut a 'A in. wide by '/:> in. long " tenon ihe full width of each part (Step I). Next, using ihe full-sized patterns we've provided, transfer ihe curved profiles to ■ the parts, then cut them oui with a band saw (Step 2). Now, use a dovetail saw to establish the shoulders and cut ihe tenons to wid,h (S,ep 3)- Cut Stock for the Posts and ■H Kails The lour posts (C) and the two rails (D) are made from five-quarter slock (which will measure about 1 in. thick). Rip the slock lo I in. square before culling the posls to a length of 17'/: in and Ihe rails to a length of 20'/-> in. Make Ihe Posls Strte thai each post has a 'A in. deep by 1 in. wide notch to accept the rails. Mark the location of each notch, then use the table saw w ith a dado head to cut them out. Use the rails to check for a good fit. Also, bore the 5/if> in. diameter through holes lor the rail flaihead machine screws (I), You'll want these holes to be square, so use the drill press or a doweling jig when you bore them. Also, make sure the holes are centered in the notch. If they are not centered, the rails may not line up wilh the post notch at assembly lime. Layout and mark the mortises in ihe posts for the headboard and footboard tenons. Once marked, use a sharp chisel to chop them out. Mark the cenlerline location of ihe post threaded insert (J) on the top end of each post, then bore a 'A in. diameter by '/- in. 65 |