Woodworker's Journal 1992-16-6, страница 68

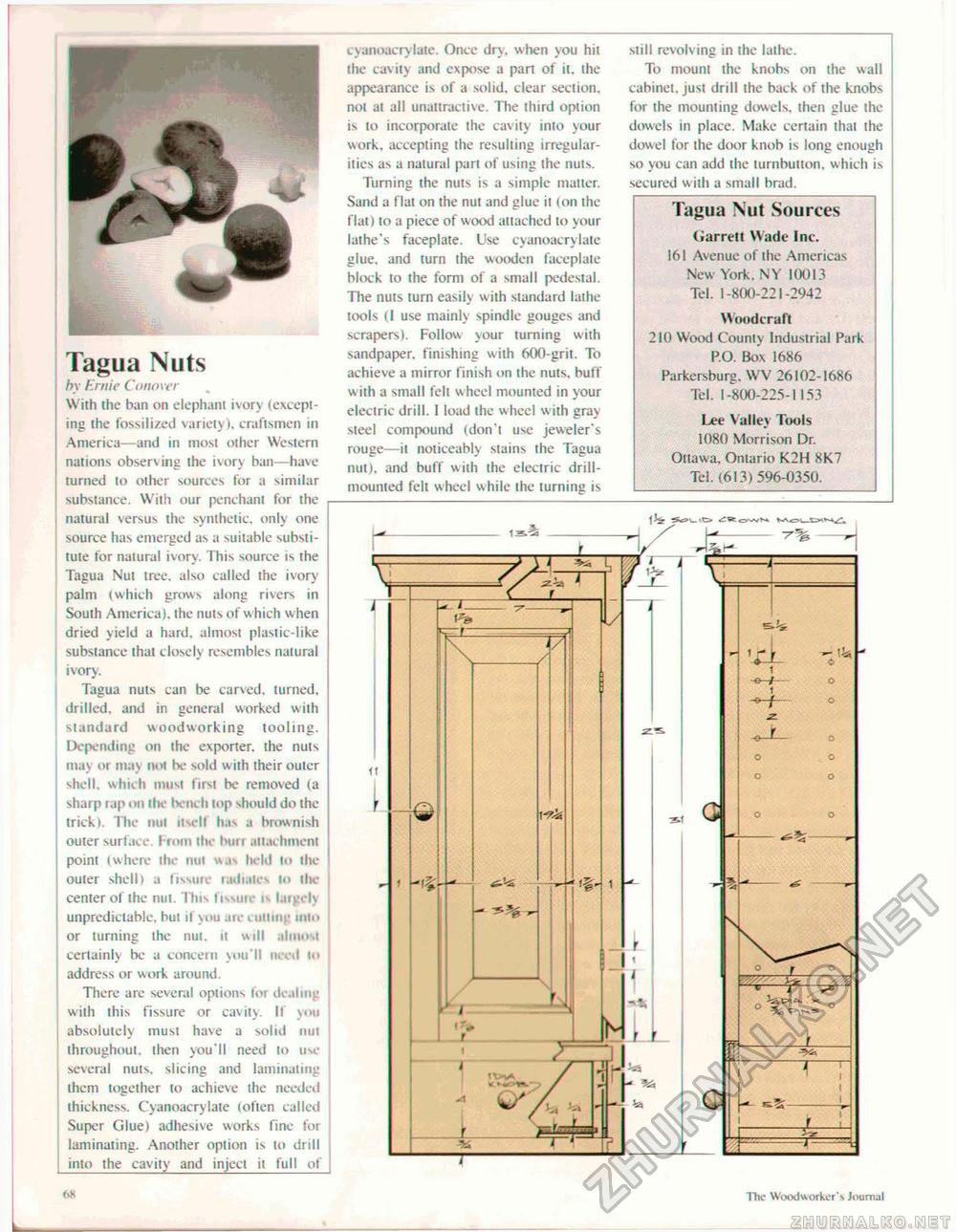

Tagua Nuts by Ernie Conover With the ban on elephant ivory (excepting the fossilized variety), craftsmen in America—and in most other Western nations observing the ivory ban—have turned to other sources for a similar substance. With our penchant for the natural versus the synthetic, only one source has emerged as a suitable substitute for natural ivory. This source is the Tagua Nut tree, also called the ivory palm (which grows along rivers in South America), the nuts of which w hen dried yield a hard, almost plastic-like substance that closely resembles natural ivory. Tagua nuts can be carved, turned, drilled, and in general worked with standard woodworking tooling. Depending on the exporter, the nuts may or inav not be sold w ith their outer shell, which must first be removed (a sharp rap on lite bench top should do the trick i. The nut itself has a brownish outer surface, f rom tin burr attachment point (where the nut was held to the outer shell) a fissure i.idiulcs to the center of the nut. This ftssute is largclv unpredictable, but if you an-1 umnr into or turning the nut. it will almost certainly be a concern you'll need lo address or work around. There are several options for dealing with this fissure or cavity. It ymi absolutely must have a solid nut throughout, then you'll need to use several nuts, slicing and laminating them together to achieve the needed thickness. Cyanoacrylate (often called Super Glue) adhesive works fine for laminating. Another option is to drill into the cavity and injcct it full of cyanoacrylate. Once dry. when you hit the cavity and expose a part of it. the appearance is of a solid, clear section, not at all unattractive. The third option is to incorporate the cavity into your work, accepting the resulting irregularities as a natural part of using the nuts. Turning the nuts is a simple matter. Sand a flat on the nut and glue it (on the flat) to a piece of wood attached to your lathe's faceplate. Use cyanoacrylate glue, and turn the wooden faceplate block to the form of a small pedestal. The nuts turn easily with standard lathe tools (I use mainly spindle gouges and scrapers). Follow your turning with sandpaper, finishing with 600-grit. To achieve a mirror finish on the nuts, buff with a small fell wheel mounted in your electric drill. I load the wheel with gray steel compound (don't use jeweler's rouge—it noticeably stains the Tagua nut), and buff with the electric drill-mounted felt wheel while the turnine is still revolving in the lathe. To mount the knobs on the wall cabinet, just drill the back of the knobs for the mounting dowels, then glue the dowels in place. Make certain that the dowel for the door knob is long enough so you can add the lurnbutton. which is secured with a small brad. Tagua Nut Sources Garrett Wade Inc. 161 Avenue of the Americas New York. NY 10013 Tel. 1 -800-221 -2942 Woodcraft 210 Wood County Industrial Park P.O. Box 1686 Parkersburg. WV 26102-1686 Tel. I-800-225-1153 Lee Valley Tools 1080 Morrison Dr. Ottawa. Ontario K2H 8K7 Tel. (613) 596-0350. The Woodworker's Journal |