Woodworker's Journal 1993-17-1, страница 30

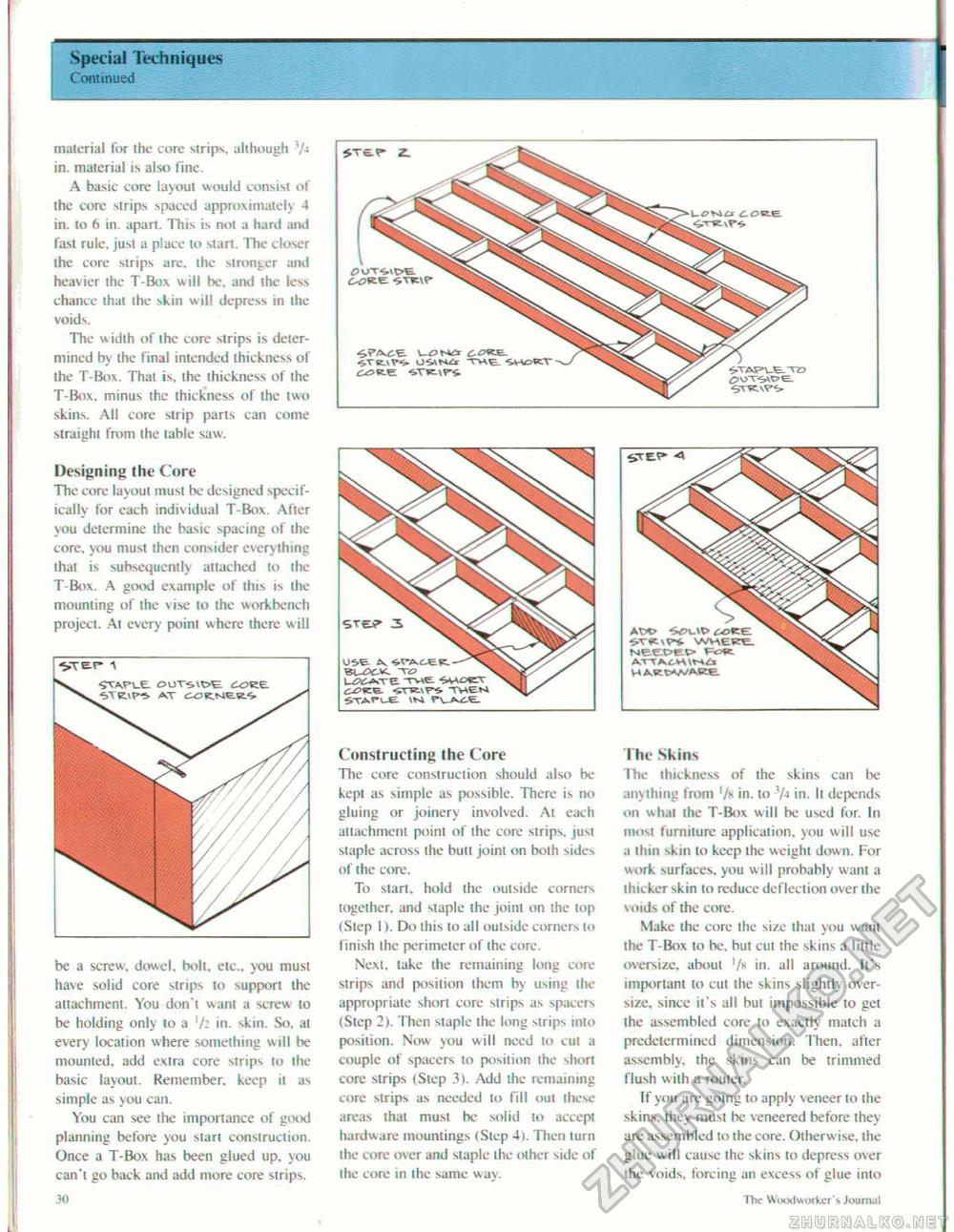

Special Techniques Continued material for the core strips, although V-i in. material is also fine. A basic core layout would consist of the core strips spaced approximate I j 4 in. to 6 in. apart. This is not a hard and fast rule, just a place to start. The closer the core strips are, the stronger and heavier the T-Box will be, and the less chance that the skin will depress in the voids. The width of Ihe core strips is determined by the final intended thickness of the T-Box. That is. the thickness of the T-Box, minus the thickness of the two skins. All core strip parts can come straight from the table saw. Designing the Core The core layout must be designed specifically for each individual T-Box. Alter you determine the basic spacing of the core, you must then consider everything that is subsequently attached to the T-Box. A good example of this is the mounting of the vise lo the workbench project. At every point where there w ill be a screw, dowel, bolt, etc.. you must have solid core strips lo support the attachment. You don't want a screw to be holding only to a in. skin. So, at every location where something will be mounted, add extra core strips to the basic layout. Remember, keep it as simple as you can. You can see Ihe importance of good planning before you siarl construction. Once a T-Box lias been glued up. you can't go back and add more core strips. IX Conslructing the Core The core construction should also be kept as simple as possible. There is no gluing or joinery involved. At each attachment point of the core strips, just staple across the bull joint on both sides of the core. To start, hold the outside corners together, and staple the joint on ihe top (Slep I). Do this to all outside corners to finish the perimeter of ihe core. Next, take the remaining long core strips and position them by using ihe appropriate short core slrips as spacers (Step 2). Then staple the long strips into position. Now you will need to cut a couple of spacers to position the short core strips (Step 3). Add the remaining core strips as needed to fill oul these areas that musi be solid lo accept hardware mountings (Step 4i. Then turn the core over and staple the other side of the core in ihe same way. The Skins The thickness of the skins can be anything from '/s in. to 7-> in. It depends on what the T-Box will be used for. In most furniture application, you will use a thin skin to keep the weight down. For work surfaces, you will probably wani a thicker skin to reduce deflection over the voids of the core. Make the core the size that you want the T-Box to be, but cut the skins a little oversize, about '/* in. ail around. It's important to cut the skins slightly oversize, since it's all but impossible to get ihe assembled core to exactly match a predetermined dimension. Then, after assembly, the skins can be trimmed flush with a router. If you are going to apply veneer to the skins, they must he veneered before they are assembled to the core. Otherwise, ihe glue w ill cause ihe skins to depress over the voids, forcing an excess of glue into The Woodworker'1, Journal STe? 3 U5.E. A. ^VAC^C. BU^C-VC. Tip uwre -rue. ^ccrr 6CKE. TWEM At*? itfUP (iOCEL Ne tpe v> /ertAtrtiNft WA.KCJWA.IZe. |