Woodworker's Journal 1993-17-1, страница 68

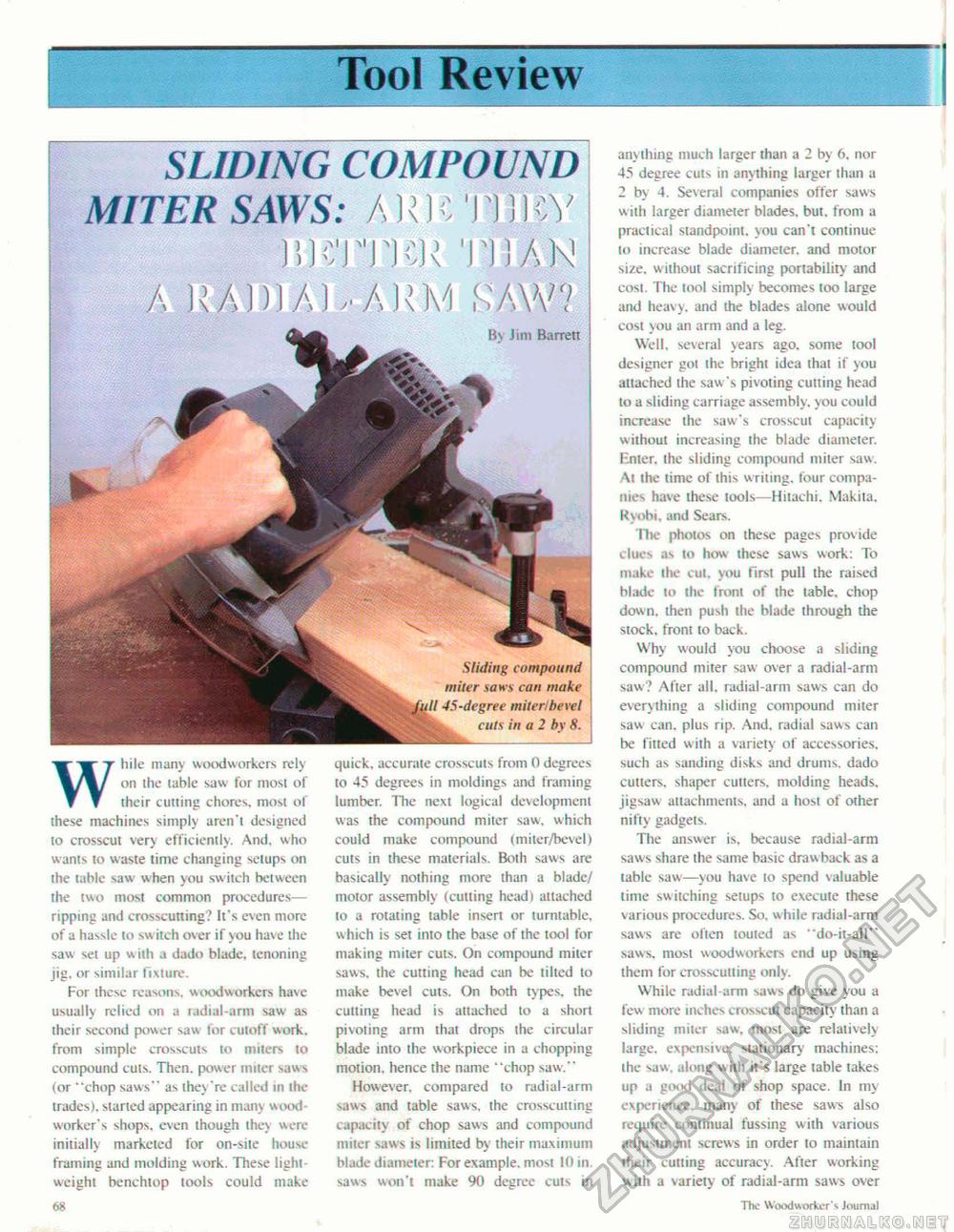

Tool Review SLIDING COMPOUND MITER SAWS: ARIC'IDICV UR'JTKR THAN A R A))] A) ARM RAW? Bv Jim Barrett While many woodworkers rely on ihe table saw for most of their cutting chores, mosi of these machines simply aren't designed to crosscut very efficiently. And, who wants to waste time changing setups on the table saw when you switch between the two most common procedures— ripping and crosscutting? It's even more of a hassle to switch over if you have the saw set up w iih a dado blade, tenoning jig. or similar fixture. For these reasons, woodworkers have usually relied on a radial-arm saw as their second power saw for cutoff work, from simple crosscuts to miters lo compound cuts. Then, power miter saws (or "chop saws" as they're called in the trades), started appearing in many woodworker's shops, even though they were initially marketed for on-site house framing and molding work. These lightweight benchtop tools could make IX quick, accurate crosscuts from 0 degrees to 45 degrees in moldings and framing lumber. The next logical development was the compound miter saw. which could make compound (miter/bevel) cuts in these materials. Both saws are basically nothing more than a blade/ motor assembly (cutting head) attached to a rotating table insert or turntable, w hich is set into the base of the tool for making miter cuts. On compound miler saws, the cutting head can be tilted to make bevel cuts. On both types, the cutting head is attached lo a short pivoting arm that drops the circular blade into the workpiece in a chopping motion, hence the name "chop saw."" However, compared to radial-arm saw^ and table saws, the crosscutting capacity of chop saws and compound miter saws is limited by their maximum blade diameter: For example, most 10 in. saws won't make 90 degree cuts in anything much larger than a 2 by 6. nor 45 degree cuts in anything larger than a 2 by 4. Several companies offer saws w ith larger diameter blades, but. from a practical standpoint, you can't continue to increase blade diameter, and motor size, without sacrificing portability and cost. The tool simply becomes too large and heavy, and ihe blades alone would cost you an arm and a leg. Well, several years ago. some tool designer got the bright idea that if you attached the saw's pivoting cutting head to a sliding carriage assembly, you could increase the saw's crosscut capacity without increasing the blade diameter. Fnter. the sliding compound miter saw. At the time of this writing, four companies have these tools—Hitachi. Makita, Rvohi, and Sears. Ihe phoios on these pages provide clues as to how these saws work: To make the cut. you first pull the raised blade to the front of the table, chop down, then push the blade through the stock, front to back. Why would you choose a sliding compound miter saw over a radial-arm saw? After all, radial-arm saws can do everything a sliding compound miter saw can. plus rip. And, radial saws can be fitted with a variety of accessories, such as sanding disks and drums, dado cutters, shaper cutters, molding heads, jigsaw attachments, and a host of other nifty gadgets. The answer is, because radial-arm saws share the same basic drawback as a table saw—you have to spend valuable lime switching setups to execute these various procedures. So. white radial-arm saws are often touted as "do-it-all" saws, most woodworkers end up using them for crosscutting only. While radial arm saws do give you a few more inches crosscut capacity than a sliding miter saw. most are relatively large, expensive, stationary machines; the saw, along with it's large table takes up a good deal of shop space. In my experience, many of these saws also require continual fussing with various adjustment screws in order to maintain their cutting accuracy. After working with a variety of radial-arm saws over The Woodworker'1, Journal |