Woodworker's Journal 1993-17-3, страница 10

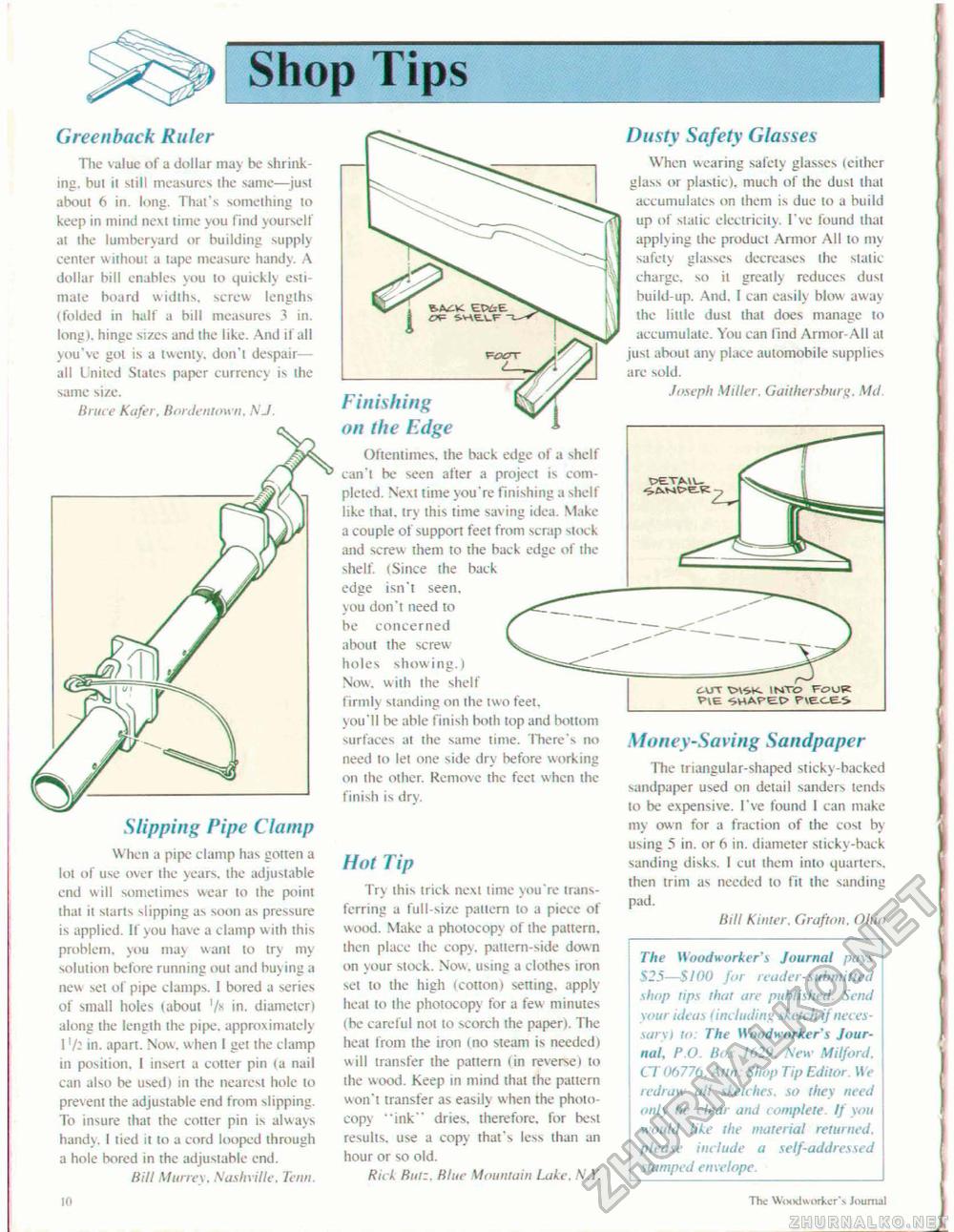

Greenback Ruler The value of a dollar may be shrinking. but ii slid measures (he same—just about 6 in. long. That's something to keep in mind next time you find yourself at the lumberyard or building supply center without a tape measure handy. A dollar bill enables you to quickly estimate board widths, screw lengths (folded in half a bill measures 3 in. long), hinge sizes and the like. And if all you've got is a twenty, don't despair— all I nited States paper currency is ihe same size. Bruce Kafer, Bordentown. NJ. Slipping Pipe Clamp When a pipe clamp has gotten a lot of use over the years, the adjustable end will sometimes wear to the point that it starts slipping as soon as pressure is applied. If you have a clamp with this problem, you may want to try my solution before running out and buying a new set of pipe clamps. I bored a series of small holes (about in. diameter) along the length the pipe, approximately 1in. apart. Now. when I get the clamp in position. I insert a cotter pin (a nail can also be used) in the nearest hole to prevent the adjustable end from slipping. To insure that the cotter pin is always handy. I tied it to a cord looped through a hole bored in the adjustable end. Bill Murrex. Nashville. Tenn. Dusty Safety Glasses When wearing safety glasses (either glass or plastic), much of the dust that accumulates on them is due to a build up of static electricity. I've found that applying the product Armor All to my safety glasses decreases (he static charge, so it greally reduces dust build-up. And. I can easily blow away the little dust that does manage to accumulate. You can find Armor-All at just about an\ place automobile supplies are sold. Joseph Miller, Gailhersburg. Mil 10 ~t"he Woodworker's Journal The Woodworker's Journal pays S25—$100 far reader-submitted shop tips that arc published. Send your ideas t including sketch ij necessary) to: The Woodworker's Journal, P.O. Bos 1629. New Milford. CT 06776. Ann: Shop Tip Editor. We redraw all sketches, so they need only he clear and complete If you would like the material returned, please include a self-addressed stamped envelope. Money-Saving Sandpaper The triangular-shaped sticky-backed sandpaper used on detail sanders lends to be expensive. I've found I can make my own for a fraction of the cost by using 5 in. or (i in. diameter sticky-back sanding disks. I cut them into quarters, then trim as needed to fit the sanding pad. Bill Kinter. Grafton. Ohio Finishing on the Edge Oftentimes, the back edge of a shelf can't be seen after a project is completed. Next time you're finishing a shelf like thai, try this time saving idea. Make a couple of support feet from scrap stock and screw them to the back edge of the shelf. (Since the hack edge isn't seen, you don't need to be concerned about ihe screw holes showing.) Now. with the shelf firmly standing on the you'll be able finish both top and bottom surfaces at the same time. There's no need to let one side dry before working on the other. Remove the feet when the finish is dry. Hot Tip Try this trick next lime you're transferring a full-size pattern to a piece of wood. Make a photocopy of the pattern, then place ihe copy, pattern-side down on your stock. Now. using a clothes iron set to the high (cotton) setting, apply heat to the photocopy for a few minutes (be careful not to scorch the paperi. The heat from the iron (no steam is needed) will transfer the pattern (in reverse) to the wood. Keep in mind that the pattern won't transfer as easily when the photocopy "ink" dries, therefore, for best results, use a copy that's less than an hour or so old. Rick Butr. Blue Mountain Lake. AM'. |