Woodworker's Journal 1993-17-3, страница 16

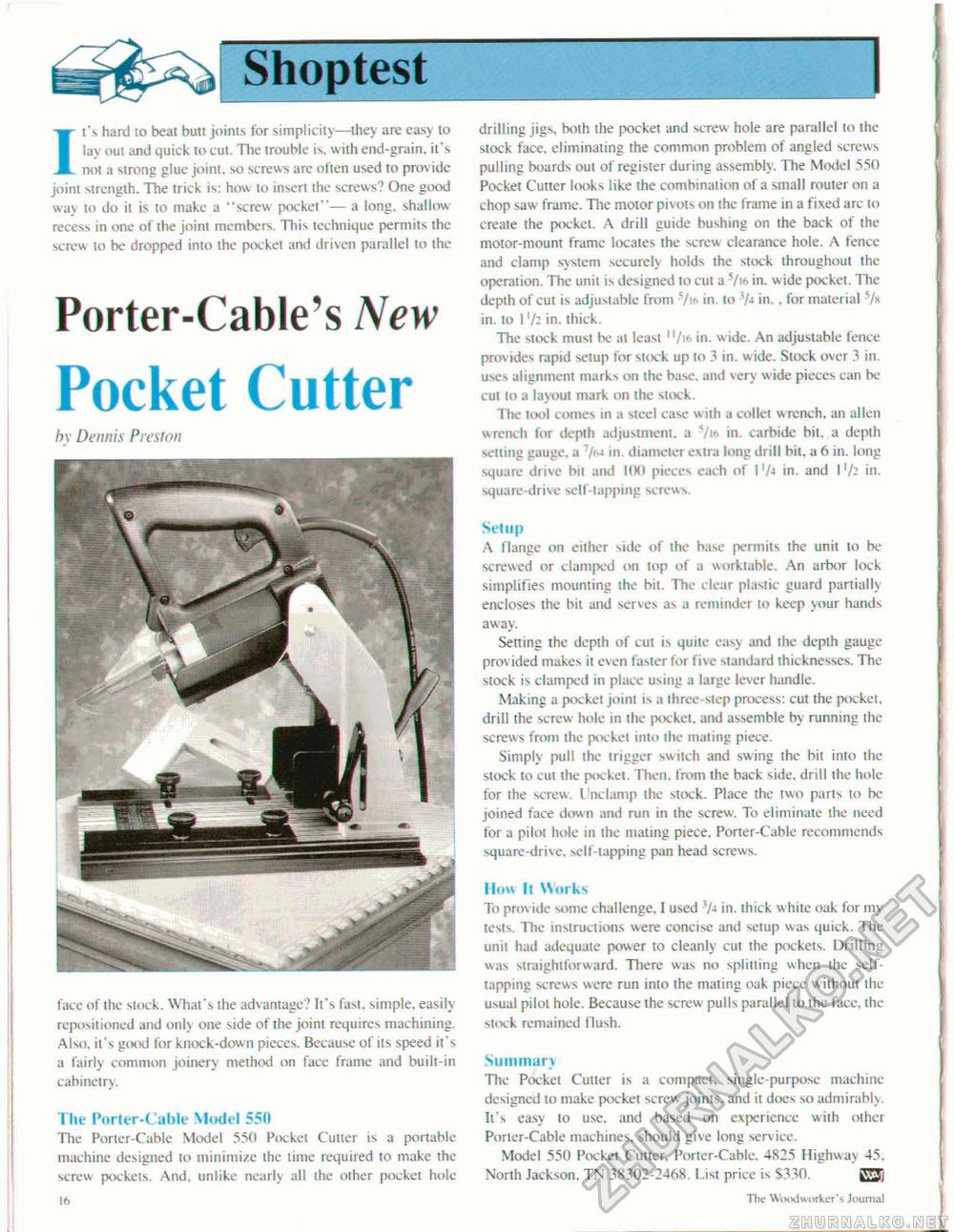

Shoptest It's hard to beat butt joints for simplicity—they are easy lo lay out and quick to cut. The trouble is. with end-grain, it's not a strong glue joint, so screws are often used to provide joint strength. Hie trick is: how to insert ihe screws? One good way lo do it is to make a "screw pocket"— a long, shallow recess in one of the joint members. This technique permits the screw to be dropped into the pocket and driven parallel to the Porter-Cable's NewPocket Cutter by Dennis Preston face of the stock. What's the advantage? It's fast, simple, easily repositioned and only one side of the joini requires machining. Also, it's good for knock-down pieces. Because of its speed it's a fairly common joinery method on face frame and built-in cabinetry. The Porter-Cable Model 551) The Porter-Cable Model 550 Pocket Cutter is a portable machine designed to minimize the time required to make the screw pockets. And, unlike nearly all the other pocket hole 16 drilling jigs, both the pocket and screw hole are parallel to the stock face, eliminating the common problem of angled screws pulling boards out of register during assembly. The Model 550 Pocket Cutter looks like the combination of a small router on a chop saw frame. The motor pivots on the frame in a fixed arc to create the pocket. A drill guide bushing on the back of the motor-mount frame locates the screw clearance hole. A fence and clamp system securely holds the stock throughout the operation. The unit is designed to cut a5/>& in. wide pocket. The depth of cut is adjustable from 5/te in. to V* in. , for material in. to I ](z in. thick. The stock must be at least "/i^ in. w ide. An adjustable fence provides rapid setup for stock up to 3 in. w ide. Slock over 3 in. uses alignment marks on the base, and very w ide pieces can be cut lo a layout mark on the stock. The tool comes in a steel case w ith a collet wrench, an alien wrench for depth adjustment, a 5M in. carbide bit. a depth setting gauge, a /m in. diameter extra long drill bil. a 6 in. long square drive bil and 100 pieces each of I ■/-* in. and l'/2 in. square-drive self-tapping screws. Setup A flange on either side of the base permits the unit lo be screwed or clamped on top of a worktablc. An arbor lock simplifies mounting ihe bit. The clear plastic guard partially encloses the bit and serves as a reminder to keep your hands away. Setting the depth of cut is quite easy and the depth gauge-provided makes it even faster for five standard thicknesses. The stock is clamped in place using a large lever handle. Making a pocket joint is a three-step process: cut the pocket, drill the screw hole in the pocket, and assemble by running the screws from the pocket into the mating piece. Simply pull the trigger switch and swing the bil into the stock to cut the pocket. Then, from the back side, drill the hole for the screw. Unclamp the stock. Place the two parts to be joined face down and run in the screw. To eliminate (he need for a pilot hole in ihe mating piece. Porter-Cable recommends square-drive, self-tapping pan head screws. How It Works To provide some challenge. I used 7-t in. thick w hite oak for my tests. The instructions were concise and setup was quick. The unit had adequate power to cleanly cut the pockets. Drilling was straightforward. There was no splitting when the self-tapping screws were run into the mating oak piece without the usual pilot hole. Because the screw pulls parallel to ihe facc, the stock remained flush. Summary The Pockei Cutter is a compact, single-purpose machine designed to make pocket screw joints, and it does so admirably, li s easy to use. and based on experience with other Porter-Cable machines, should give long service. Model 550 Pocket Cutter, Porter-Cable. 4825 Highway 45, North Jackson. TN 38302-2468. List price is $330. £3", ~t"he Woodworker's Journal |