Woodworker's Journal 1993-17-4, страница 16

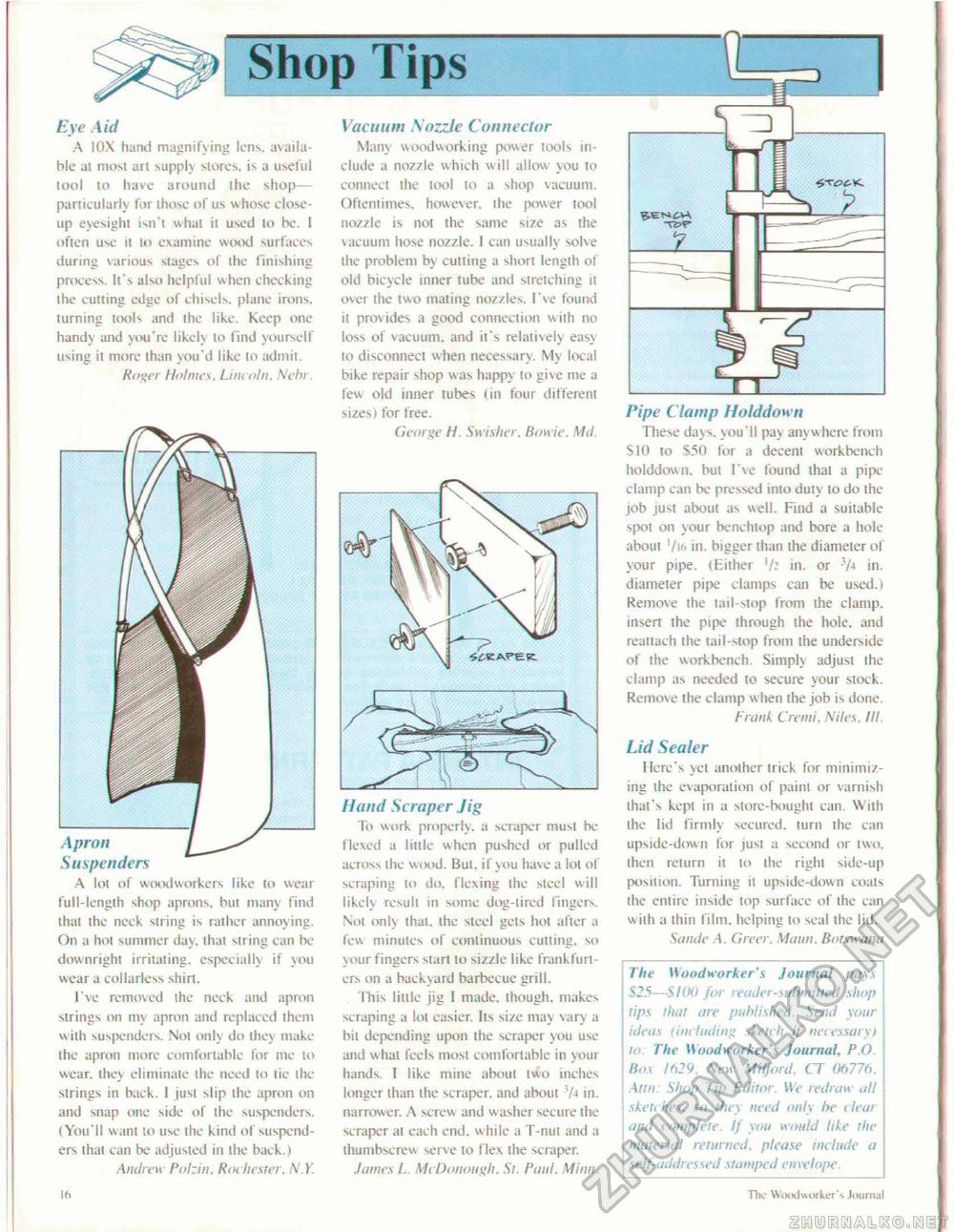

Shop Tips Eye Aid A 10X hand magnifying lens, available ai most art supply stores, is a useful tool to have around the shop— particularly for those of us whose close-up eyesight isn't what it used to be. I often use il to examine wood surfaces during various stages of the finishing process. It's also helpful when checking the cutting edge of chisels, plane irons, turning tools and the like. Keep one hand; and you're likely to find yourself using it more than you'd like to admit. Roger Holmes, Lincoln. Nebr. Vacuum Nozzle Connector Many woodworking power tools include a nozzle which will allow you to connect the tool to a shop vacuum. Oftentimes, however, the power tool nozzle is not the same size as the vacuum hose nozzle. I can usually solve the problem by cutting a short length of old bicycle inner tube and stretching it over the two mating nozzles. I've found it provides a good connection with no loss of vacuum, and it's relatively easy to disconnect when necessary. My local bike repair shop was happy to give me a few old inner tubes (in four different sizes) for free. George H. Swisher, Bowie. Md. Hand Scraper Jig To work properly, a scraper must be flexed a little when pushed or pulled across the wood. Bui. if you have a lot of scraping to do. flexing the steel will likely result in some dog-tired fingers. Not only that, the steel gets hot after a few minutes of continuous cutting, so your fingers start to sizzle like frankfurters on a backyard barbecue grill. This little jig I made, though, makes scraping a lot easier. Its size may vary a bit depending upon the scraper you use and w hat feels most comfortable in your hands. I like mine about two inches longer than the scraper, and about 7-t in. narrower. A screw and washer secure the scraper at each end. while a T-nut and a thumbscrew serve to flex the scraper. James L McDonough. Si, Paul. Minn. Pipe Clamp Holddown These days. you'll pay anywhere from S10 to S5(J lor a decent workbench holddown, but I've found that a pipe clamp can be pressed into duty to do the job just about as well. Find a suitable spot on your benchtop and bore a hole about l/i6 in. bigger than the diameter of your pipe. (Either Ui ill- or in. diameter pipe clamps can be used.) Remove the tail-stop from the clamp, insert the pipe through the hole, and reattach the tail slop from the underside of the workbench. Simply adjust the clamp as needed to secure your stock. Remove the clamp w hen the job is done. Frank Cremi, Niles. III. Lid Sealer Here's vet another trick for minimizing the evaporation of paint or varnish that's kept in a store-bought can. With the lid firmly secured, turn the can upside-down for just a second or two. then return it to the right side-up position. Turning it upside-down coats the entire inside top surface of the can with a thin film, helping to seal the lid. Sonde ,4. Greer. Mann, Botswana The Woodworker's Journal pays 525—$100 for reader-submitted shop tips that are published. Send your ideas (including sketch if necessary} to: The Woodworker's Journal. P.O. Box 1629. Sew Milford. CT 06776. Attn: Shop Tip F.ditor. Wc redraw all sketches, so they need only be cleat and complete. If you would like the materiaI returned, please include a self-addressed stamped envelope. Ifi Tin; WtxidttorktT's Journal Apron Suspenders A lot of woodworkers like lo wear full-length shop aprons, hut many find that the neck siring is rather annoying. On a hot summer day. that string can be downright irritating, especially if you wear a collarless shirt. I've removed the neck and apron strings on my apron and replaced them w ith suspenders. Not only do they make the apron more comfortable for me to wear, ihey eliminate the need to tic the strings in back. I just slip the apron on and snap one side of the suspenders. (You'll want to use the kind of suspenders that can be adjusted in the back.) Andrew Polzin. Rochester. NY. |