Woodworker's Journal 1993-17-4, страница 26

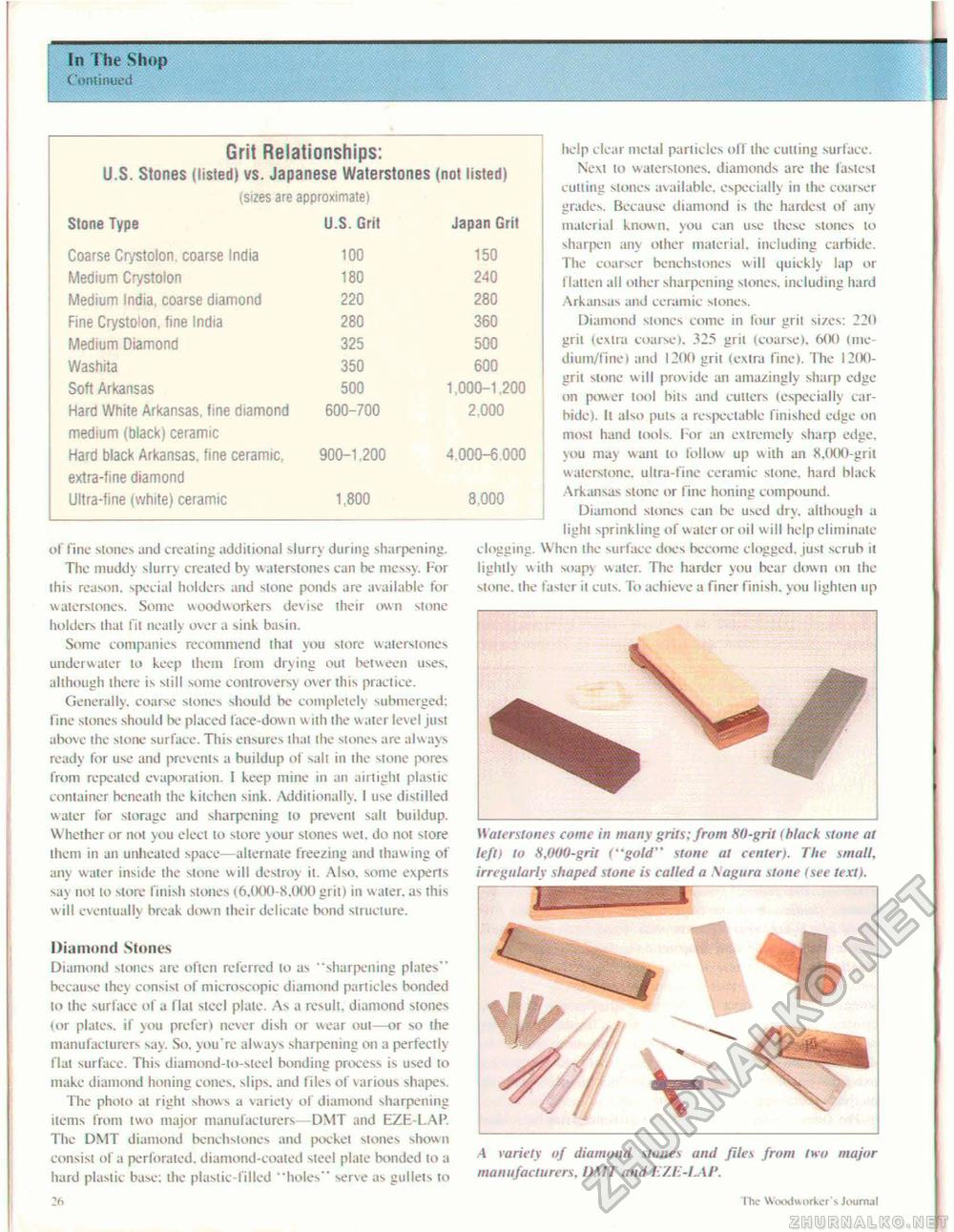

hi The Shop Continued Grit Relationships: U.S. Stones (listed) vs. Japanese Waterstones (not listed) (sizes are approximate) Stone Type U.S. Grit Coarse Crystolon. coarse India 100 Medium Crystolon 180 Medium India, coarse diamond 220 Fine Crystolon, fine India 280 Medium Diamond 325 Washita 350 Soft Arkansas 500 Hard White Arkansas, fine diamond 600-700 medium (black) ceramic Hard black Arkansas, fine ceramic, 900-1.200 extra-fine diamond Ultra-fine (white) ceramic 1,800 Japan Grit 150 240 280 360 500 600 1,000-1,200 2,000 4.000-6.000 8,000 of I ine stones and creating additional slurry during sharpening. The muddy slurry created by waterstones can be messy, For this reason, special holders and stone ponds are available tor waterstones. Some woodworkers devise their own stone holders that fit neatly over a sink basin. Some companies recommend that you store waterstones underwater to keep them from drying out between uses, although there is still some controversy over this practice. Generally, coarse stones should be completely submerged; fine stones should be placed face-dow n w ith the water level just above the stone surface. This ensures that the stones are always ready for use and prevents a buildup of salt in the stone pores from repealed evaporation. I keep mine in an airtight plastic container beneath the kitchen sink. Additionally. I use distilled water for storage and sharpening to prevent salt buildup. Whether or not you elect to store your stones wet. do not store them in an unhealed space—alternate freezing and thawing of any water inside the stone will destroy it. Also, some experts say not to store finish stones (6.000-8.000 grit) in water, as this will eventually break down their delicate bond structure- Diamond Stones Diamond stones are often referred to as "sharpening plates" because they consist of microscopic diamond particles bonded to the surface of a flat steel plate. As a result, diamond stones (or plates, if you prefer) never dish or wear out—or so the manufacturers say. So. you're always sharpening on a perfectly flat surface. This diamond-to-sieel bonding process is used to make diamond honing cones, slips, and files o! \arious shapes. The photo al right shows a variety of diamond sharpening items from two major manufacturers—DMT and EZE-LAP. The DMT diamond benchstones and pocket stones shown consist of a perforated, diamond-coated steel plate bonded to a hard plastic base; the plastic-filled "holes" serve as gullets to help clear metal particles off the culling surface. Next lo waterstones. diamonds are ihe fastest cutting stones available, especially in the coarser grades. Because diamond is the hardest of any material known, you can use these slones to sharpen any other material, including carbide. The coarser benchstones will quickly lap or flatten all other sharpening stones, including hard Arkansas and ceramic slones. Diamond stones come in four grit sizes: 220 grit (extra coarse), 325 grit (coarse I, 600 (medium/fine) and 1200 grit (extra fine). The 1200-grii stone will provide an amazingly sharp edge on power tool bits and cutters (especially carbide). It also puts a respectable finished edge on most hand tools. For an extremely sharp edge, you may want lo follow up with an 8,000-grit walcrstone, ultra-fine ceramic stone, hard black Arkansas stone or l ine honing compound. Diamond slones can be used dry. although a light sprinkling of water or oil w ill help eliminate clogging. When the surface does become clogged, just scrub it lightly with soapy water. The harder you bear down on the stone, the faster it cuts. To achieve a finer finish, you lighten up Walerstones come in many grits; from HO-grit I Mack stone al left) to 8,000-grit ("gold" stone al center). The small, irregularly shaped Stone is called a \agura stone (see text I. /4 variety of diamond stones and files from two major manufacturers. DMT and l:. '/.li-l.AV. t(l The Woodworker's Journal |