Woodworker's Journal 1993-17-4, страница 50

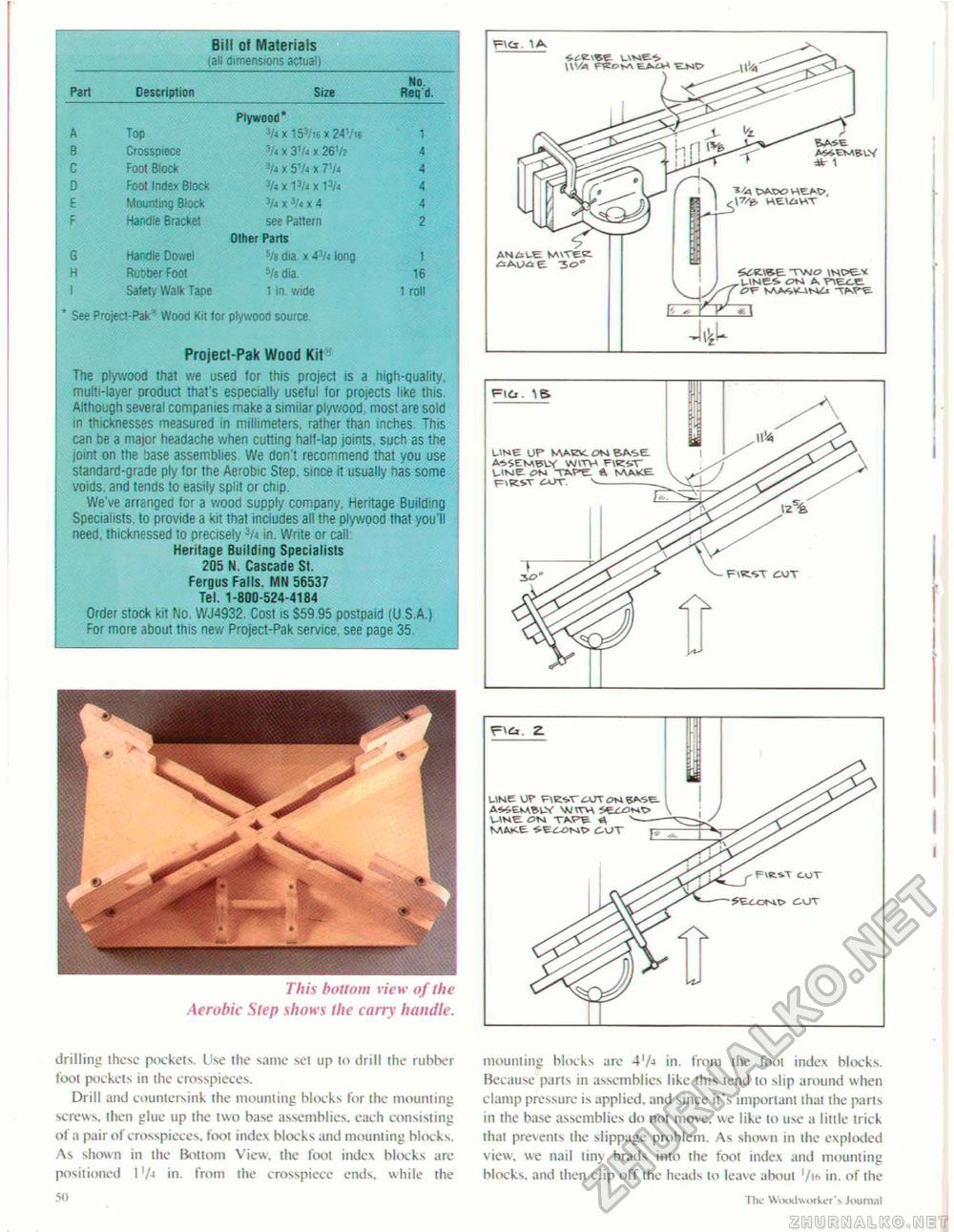

Bill of Materials (all dimensions actual) Part Description Size Req'd. Plywood* A Top 2/4 * m,B * 24'/i6 1 B Crosspiece % > 3<A x 26V? 4 G Foot Block 3/4 * 5V4 x VI* 4 D Foot Index Block 2U x I3/* x 4 E Mounting Block 3/» x x 4 4 F Handle Bracket see Pattern 2 Other Parts 6 Handle Dowel Ve dia x 4Vj long 1 H Rutjber Foot s/e dia 16 I Safety Walk Tape 1 in wide 1 roll * See Project-Pak' Wood Kit tor plywood source. Project-Pak Wood Kil The plywood that we used for this projecl is a high-quality, multi-layer product that's especially useful for projects like this. Although several companies make a similar plywood, most are sold in thicknesses measured in miliimefers, rather than inches. This can be a major headache when cutting half-lap joints, such as the joint on the base assemblies We don't recommend that you use standard-grade ply (or the Aerobic Step, since if usually has some voids, and tends lo easily split or chip. We've arranged for a wood supply company. Heritage Building Specialists, lo provide a kit that includes all the plywood thai you'll need, thicknessed lo precisely 3/4 in. Write or call: Heritage Building Specialists 205 N. Cascade St. Fergus Falls. MN 56537 Tel. 1-800-524-4184 Order stock kit No. WJ4932. Cost is $59 95 postpaid (U.S.A.) For more about this new Project-Pak service, see page 35 This bottom \iew of the Aerobic Step shows the carry handle. drilling these pockets. Use the same set up to drill the rubber foot pockets in the crosspieces. Drill and countersink the mounting blocks for the mounting screws, then glue up the two base assemblies, each consisting of a pair of crosspieces. foot index blocks and mounting blocks. As shown in the Bottom View, the fool index blocks are positioned l '/■» in. from ihe crosspieee ends, while the 50 mounting blocks are 4'A in. from the foot index blocks. Because parts in assemblies like this tend to slip around when clamp pressure is applied, and since it's important ihat the parts in the base assemblies do not move, we like to use a little trick thai prevents the slippage problem. As shown in the exploded view, we nail liny brads into the fool index and mounting blocks, and then clip off the heads to leave about '/«■ in. of the t(l The Woodworker's Journal |