Woodworker's Journal 1993-17-6, страница 24

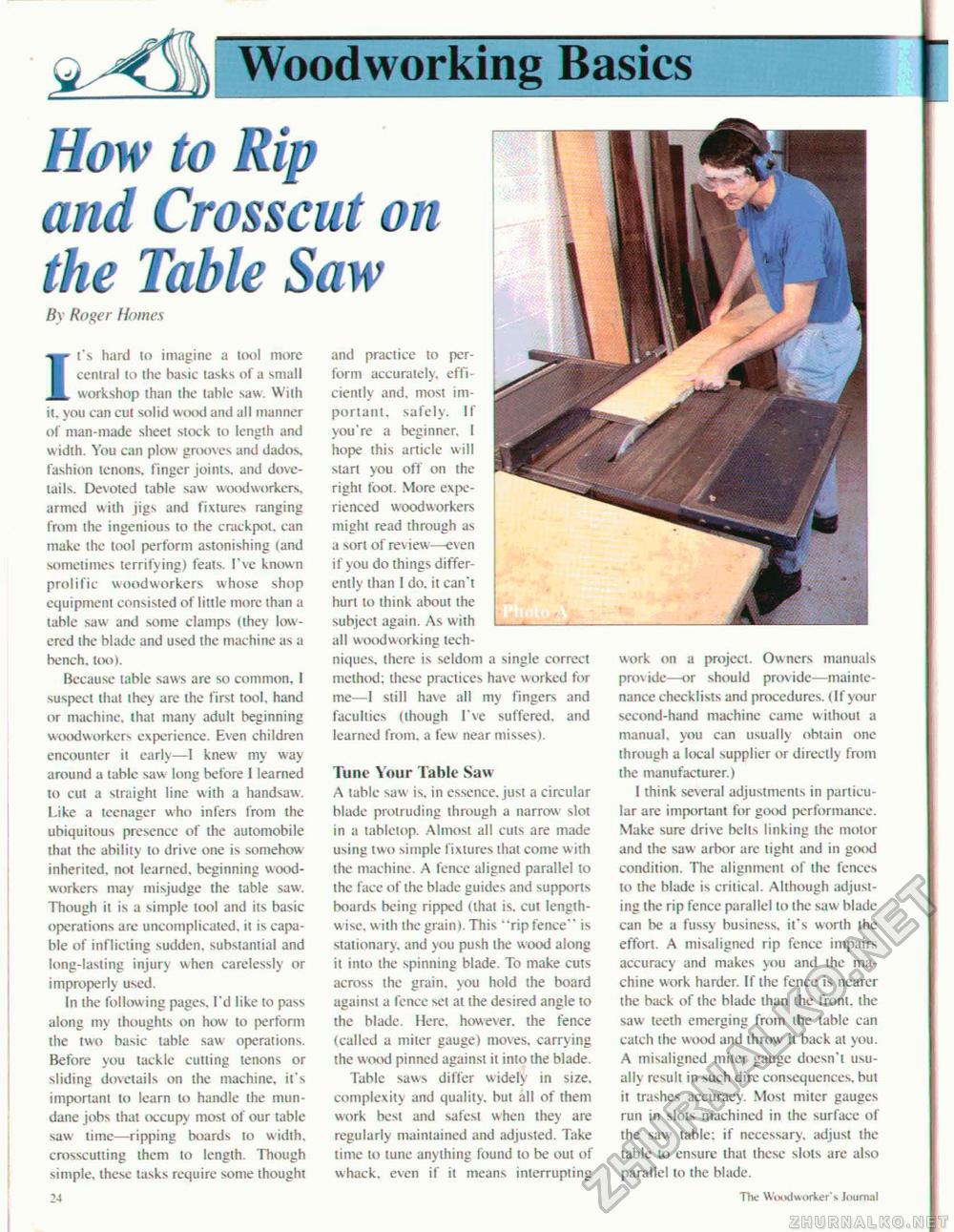

Woodworking Basics How to Rip and Crosscut on the Table Saw Bx Roger Homes It's hard lo imagine a tool more central to the basic tasks of a small , workshop than the table saw. With it. you can cut solid wood and all manner of man-made sheet stock to length and width. You can plow grooves and dados, fashion tenons, finger joints, and dovetails. Devoted table saw woodworkers, armed with jigs and fixtures ranging from the ingenious to the crackpot, can make the tool perform astonishing (and sometimes terrifying) feats. I've known prolific woodworkers whose shop equipment consisted of little more than a table saw and some clamps (they lowered the blade and used the machine as a bench, loo). Because table saws are so common. I suspect that they are the first tool, hand or machine, that many adult beginning woodworkers experience. Even children encounter it early—I knew my way around a table saw long before 1 learned to cut a straight line with a handsaw-. Like a teenager who infers from the ubiquitous presence of the automobile that the ability to drive one is somehow inherited, not learned, beginning woodworkers may misjudge the table saw. Though it is a simple tool and its basic operations arc uncomplicated, it is capable of inflicting sudden, substantial and long-lasting injury when carelessly or improperly used. In the following pages. I'd like to pass along my thoughts on how to perform the two basic table saw operations. Before you tackle cutting tenons or sliding dovetails on the machine, it's important to learn to handle the mundane jobs that occupy most of our table saw lime—ripping boards to width, crosscutting them lo length. Though simple, these tasks require some thought 24 and practice to perform accurately, efficiently and, most important, safely. If you're a beginner. I hope this article will start you off on the right foot. More experienced woodworkers might read through as a sort of review—even if you do things differently than I do. it can'i hurl to think about the subject again. As with all woodworking techniques, there is seldom a single correct method: these practices have worked for me—I still have all my fingers and faculties {though I've suffered, and learned from, a few near misses). Tune Your Table Saw A table saw is. in essence, just a circular blade protruding through a narrow slot in a tahletop. Almost all cuts are made using two simple fixtures that come with the machine. A fence aligned parallel to the face of the blade guides and supports boards being ripped (that is. cut lengthwise, with the grain). This "rip fence" is stationary, and you push the wood along it into ihe spinning blade. To make cuts across the grain, you hold the board against a fence set al the desired angle to the blade. Here, however, the fence (called u miter gauge) moves, carrying the wotxl pinned against it into the blade. Table saws differ widely in size, complexity and quality, but all of them work best and safest when they are regularly maintained and adjusted. Take time to tune anything found lo be out of whack, even if it means interrupting work on a project. Owners manuals provide—or should provide—maintenance checklists and procedures. (If your second-hand machine came without a manual, you can usually obtain one through a local supplier or directly from the manufacturer.) I think several adjustments in particular are important for good performance. Make sure drive belts linking the motor and the saw arbor arc light and in good condition. The alignment of the fences lo the blade is critical. Although adjusting the rip fence parallel to the saw blade can be a fussy business, it's worth the effort. A misaligned rip fence impairs accuracy and makes you and ihe machine work harder. If the fence is nearer the back of the blade than the front, ihe saw teeth emerging from the lable can catch the wood and thrmv ii back al you. A misaligned miter gauge doesn't usually result in such dire consequences, bul it trashes accuracy. Most miter gauges run in slots machined in the surface of the saw table: if necessary, adjust the table lo ensure that these slots are also parallel to the blade. The WimxJworker's Journal |