Woodworker's Journal 1993-17-6, страница 25

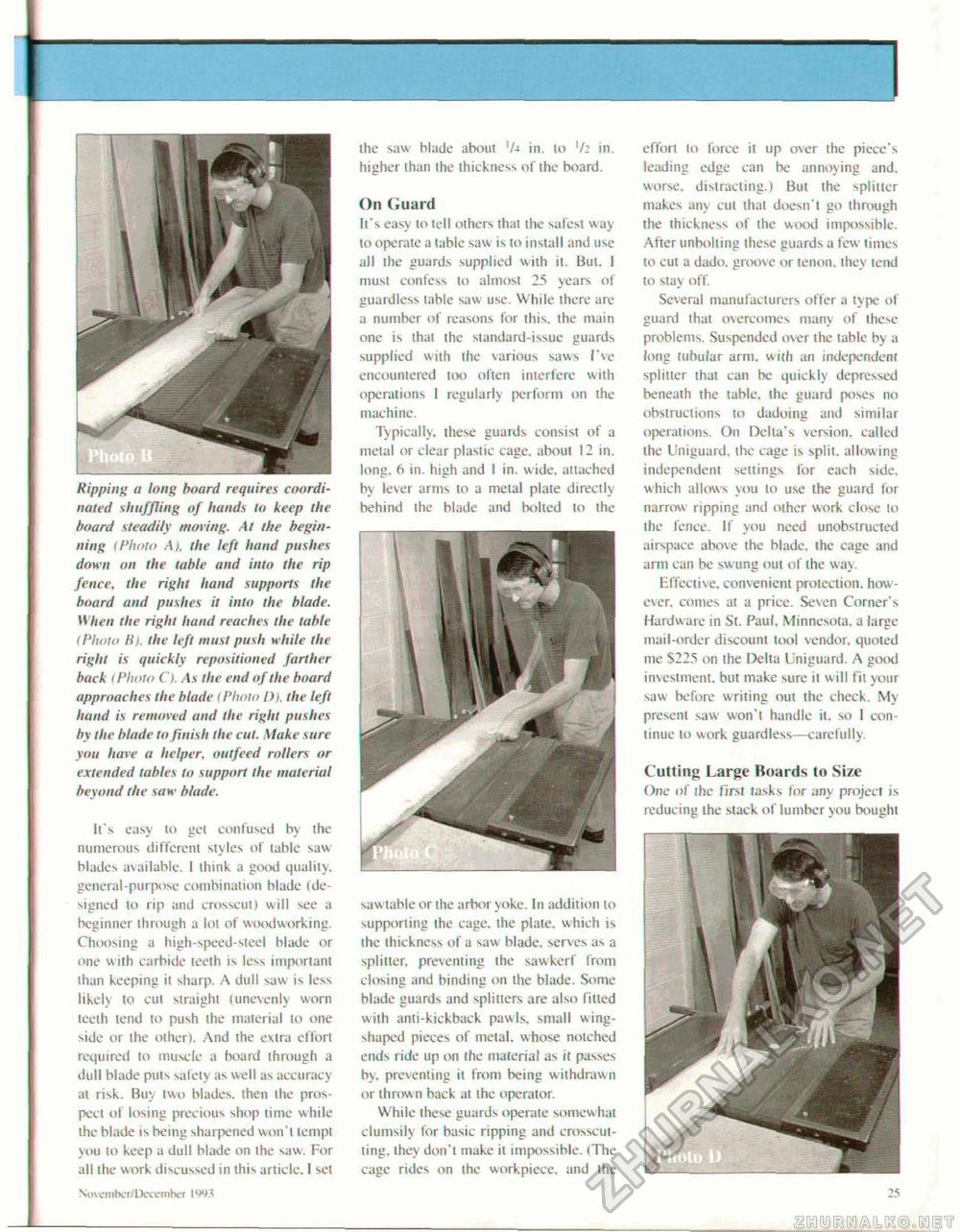

Kipping a long board requires coordinated shuffling of hands to keep the board steadily moving. At the beginning (Photo A). the left hand pushes down on the table and into the rip fence, the right hand supports the board and pushes it into the blade. When the right hand reaches the (able (Photo II). the left must push while the right is quickly repositioned farther back l Photo O. As the end of the board approaches the blade I Photo D), the left hand is removed and the right pushes by the blade to finish the cut. Make sure you have a helper, out feed rollers or extended tables to support the material beyond (he saw blade. U s easy to get contused by the numerous different styles of table saw blades available. I think a good quality, general-purpose combination blade (designed to rip and crosscut) will see a beginner through a lot of woodworking. Choosing a high speed-steel blade or one with carbide teeth is less important than keeping it sharp. A dull saw is less likely to cut straight (unevenly worn teeth lend to push the material to one side or the other). And the extra effort required to muscle a board through a dull blade puts safety as well as accuracy at risk. Buy two blades, then the prospect of losing precious shop time while the blade is being sharpened won't tempt you to keep a dull blade on the saw. For all the work discussed in this article. I set Nincmher/Dceemher IW3 the saw hlade about 'A in. lo '/: in. higher than the thickness of the board. On (iuard It's easy to tell others that the safest way to operate a table saw is to install and use all the guards supplied with it. But, 1 must confess to almost 25 years of guardless table saw use. While there are a number of reasons lor this, the main one is that the standard-issue guards supplied with the various saws I've encountered too often interfere with operations I regularly perform on the machine. Typically, these guards consist of a metal or clear plastic cage, about 12 in. long. 6 in. high and I in. wide, attached by lever arms to a metal plate directly behind the blade and bolted to the saw table or the arbor yoke. In addition to supporting the cage, the plate, which is the thickness of a saw blade, serves as a splitter, preventing the sawkerf from closing and binding on the blade. Some hlade guards and splitters are also fitted with anti-kickback pawls, small wing-shaped pieces of metal, whose notched ends ride up on the material as it passes by. preventing it from being withdrawn or thrown back at the operator. While these guards operate somewhat clumsily tor basic ripping and crosscut-ting. they don't make it impossible. (The cage rides on the workpiece, and the effort to force it up over the piece's leading edge can be annoying and. worse, distracting.) But the splitter makes any cut that doesn't go through the thickness of the wood impossible. After unbolting these guards a few times to cut a dado. gri>ove or tenon, they tend to stay off. Several manufacturers offer a type of guard that overcomes many of these problems. Suspended over the table by a long tubular arm. with an independent splitter that can be quickly depressed beneath the table, the guard poses no obstructions to dadoing and similar operations. On Delta's version, called the Uniguard. the cage is split, allowing independent settings for each side, which allows you lo use the guard for narrow ripping and other work close lo ihe fence. If you need unobstructed airspace above the blade, the cage and arm can be swung out of the way. Effective, convenient protection, how ever. comes at a price. Seven Corner's Hardw are in St. Paul, Minnesota, a large mail-order discount tool vendor, quoted me S225 on the Delta liniguard. A good investment, bur make sure it will fit your saw before writing out the check. My present saw won't handle it. so 1 continue to work guardless—carefully. Cutting Large Boards to Size One of the first tasks for any project is reducing ihe stack of lumber you bought 25 |