Woodworker's Journal 1993-17-6, страница 26

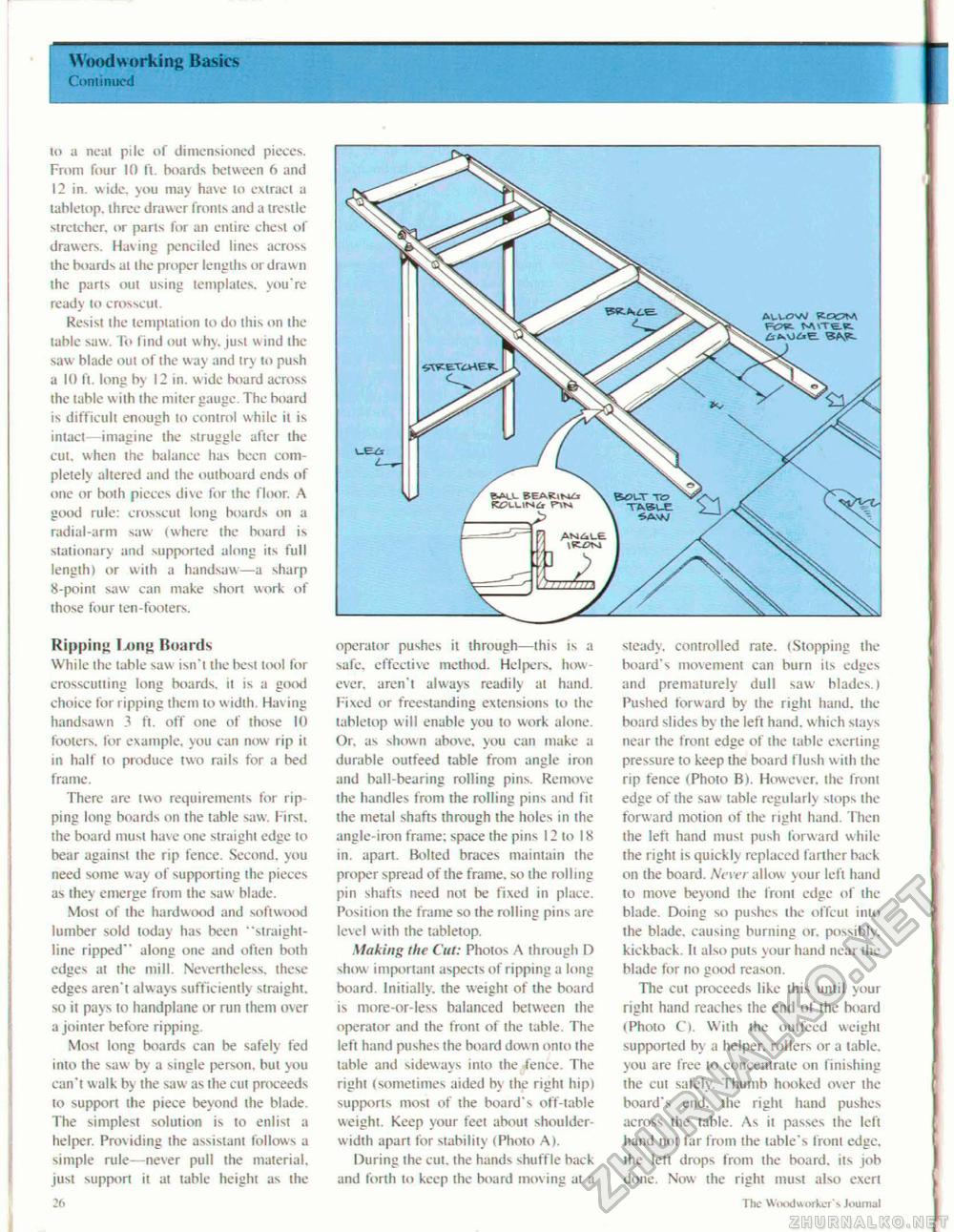

Woodworking Basics Continued to a neat pile of dimensioned pieces. From four 10 ft. boards between 6 and 12 in. wide, you may have lo extract a tabletop. three drawer fronts and a trestle stretcher, or parts for an entire chest of drawers. Having penciled lines across the boards al the proper lengths or drawn ihe parts out using templates, you're ready to crosscut. Resist the temptation to do this on the table saw. To find out why. just wind the saw blade out of the way and try to push a 10 ft, long by 12 in. wide board across the table with the miter gauge. The board is difficult enough to control while it is intacl—imagine the struggle after the cut. when the balance has been com pletelv altered and the outboard ends of one or both pieces dive for the fltKtr, A good rule: crosscut long boards on a radial-arm saw (where the board is stationary and supported along its full length) or with a handsaw—a sharp 8-point saw- can make short work of ihose four ten-footers. Ripping Ix>ng Boards While the table saw isn't the best tool for crosscutting long boards, it is a good choice for ripping them to width. Having handsawn 3 ft. off one of those 10 footers, for example, you can now rip ii in halt to produce two rails for a bed frame. There are two requirements for ripping long boards on the table saw. l ust, the board must have one straight edge to bear against ihe rip fence. Second, you need some way of supporting the pieces as they emerge from the saw blade. Most of the hardwood and softwood lumber sold today has been "straighl-line ripped" along one and often both edges at the mill. Nevertheless, these edges aren't always sufficiently straight, so it pays to handpfarte or run them over a joinier before ripping. Most long boards can be safely fed into the saw by a single person, but you can't walk by the saw as the cut proceeds to support the piece beyond the blade, The simplest solution is to enlist a helper. Providing the assistant follows a simple rule—never pull the material, just support it at table height as the 26 operator pushes it through—this is a safe, effective method. Helpers, however. aren't always readily al hand. Fixed or freestanding extensions to the tabletop w ill enable you to work alone. Or, as show n above, you can make a durable outfeed table from angle iron and ball-bearing rolling pins. Remove Ihe handles from the rolling pins and fit the metal shafts through the holes in the angle-iron frame: space the pins 12 to IS in. apart. Bolted braces maintain the proper spread of the frame, so the rolling pin shafts need not be fixed in place. Position the frame so the rolling pins are level with the tabletop. Making the Cut: Photos A through D show important aspects of ripping a long board. Initially, the weight of the board is more-or-less balanced between the operator and the front of ihe table. The left hand pushes the board dow n onto the table and sideways into the fence. The right (sometimes aided by the right hip) supports most of the board's off-table weight. Keep your feet about shoulder-width apart for stability (Photo A). During the cut. the hands shuffle back and forth to keep the board moving at a steady, controlled rate. (Stopping the board's movement can burn its edges and prematurely dull saw blades.) Pushed forward by the right hand, the board slides by the left hand, which stay s near the front edge of the table exerting pressure to keep the board flush with the rip fence (Photo B). However, the from edge of the saw table regularly slops the forw ard motion of the right hand. Then the left hand must push forward while the right is quickly replaced farther back on the board. Never allow your left hand to move beyond the front edge of ihe blade. Doing so pushes the offcul into the blade, causing burning or. possibly, kickback. It also puts your hand near the blade for no good reason. The cut proceeds like this until your right hand reaches the end of the board (Photo C). With the outfeed weight supported by a helper, rollers or a table, you are free to concentrate on finishing the cut safely. Thumb hooked over the board's end. ihe right hand pushes across the table. As it passes the left hand not far from the table's front edge, the left drops from the board, its job done. Now the right must also exert The Woodworker's Journal |