Woodworker's Journal 1994-18-2, страница 37

plunge routers. Secondly, our insert mounts with a clever adjustable block system. With this system, you merely cut the hole in the lop to fit the insert—there are no lussv rabbets or grooves to cut. The machined blocks then enable you to simply level the insert with vour table top b\ turning the built-in thumbscrews. The adjustable block system is included along with all the other hardware you need in a Hardware Kit (sec Sources). Gather Your Materials We recommend that you have all hardware, and _\our fence, on hand before starting work on the router table. Other than the hardw are and fence, your material needs are minimal—some :,/4 in. thick plywood for the top (A) and cord core (I). Formica or other plastic laminate (B i as needed to cover the top. 1 '/s in. thick oak (or other hardwood| for the various frame parts (C. I). E. F). -V4 in. oak for the switch mount (111 and cleat tK). in. and '/4 in. plywood respectively for the leveler shim (Gl and cord cap (J), and 1 Ul in oak for the leg (L). Laminate Top Using contact cement, apply the plastic laminate to the top. If you haven't used contact cement before. the process is fairly simple. You coat both surfaces, let the contact cement dry to the touch, then position the laminate over the surface you w ant covered. The laminate is always cut slightlv oversize. then trimmed llush with a laminate trimming bit in the router (or better yet a small router called a "laminate trimmer"). The laminating process thai we followed for the router table was lo lirsi laminate the end edges, next the side edges, then the bottom, and lastly the top. Cut Insert Hole and Miter Groove Once your laminate is in place, mark for and cut the hole for the acrylic insen (M) and ihe groove for the miter gauge. To cut the insert hole, first use the actual insert to mark Lhe hole profile. Next, drill a starter hole for your jigsaw. Use a fine tooth blade (a metal cutting blade is best) and work slowly to avoid chipping the laminate. For the miter slot, if you have a sharp stack dado set, and a large enough table saw. you can establish the miter slot on your table saw. But handling a panel as large as our router table top on a Bill of Materials (all dimensions actual) Bill of Materials (all dimensions actual)

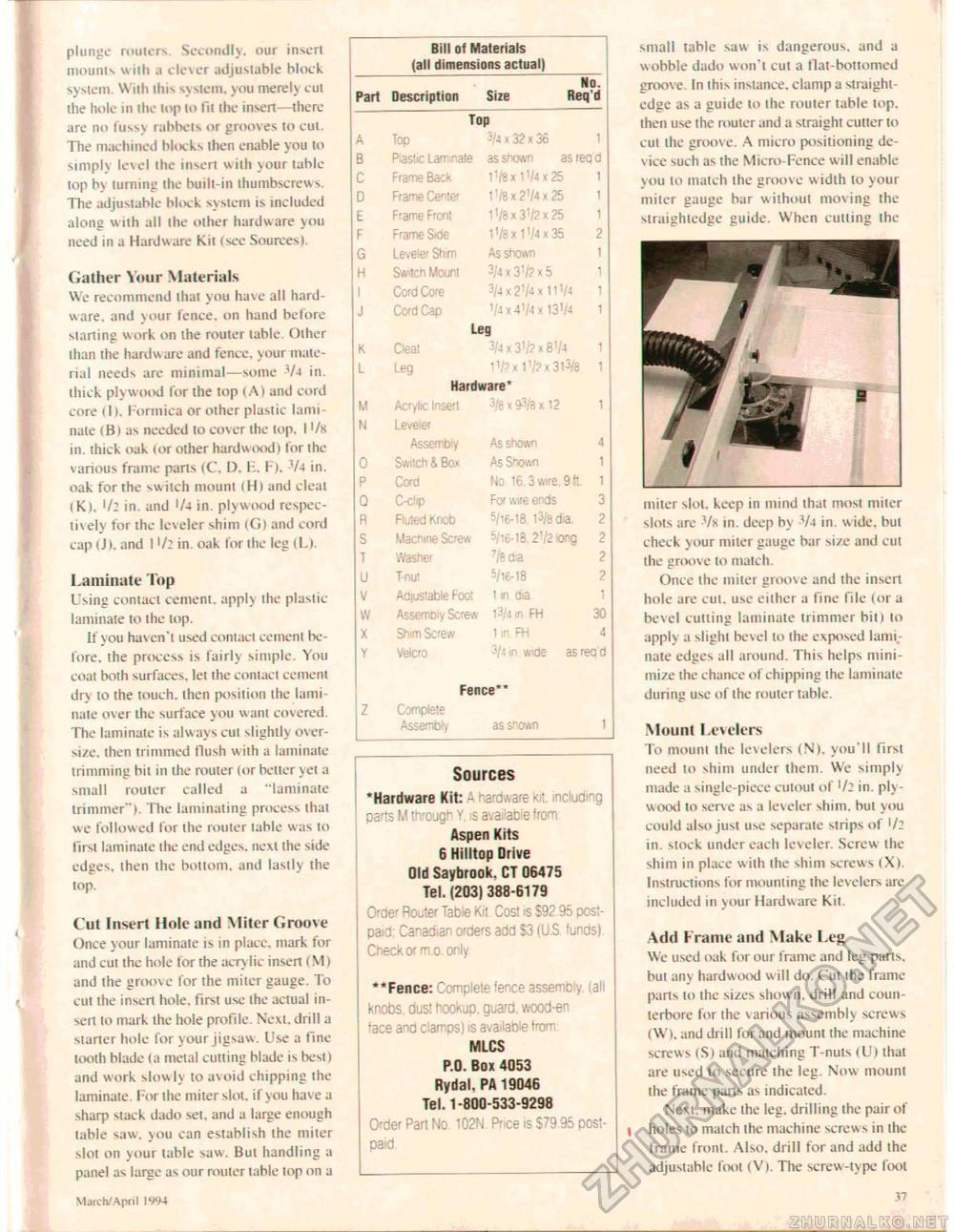

Sources 'Hardware Kit: 4 hardware kit. including parts M mrougfc Y s avai'aoie from Aspen Kits 6 Hilltop Drive Old Saybrook. CT 06475 Tel. (203) 388-6179 Order Router Tabie Kit Cost is S92 95 postpaid: Canadian orders add S3 (U.S. funds) Check or m.o. only **Fence: Complete fence assembly, (all knobs, dust hookup, guard, wood-en face and clamps) is available from MLCS P.O. Box 4053 Rydai. PA 19046 Tel. 1-800-533-9298 Order Part No 102N. Price is $79 95 postpaid small table saw is dangerous, and a wobble dado won't cut a flat-bottomed groov e. In this instance, clamp a straightedge as a guide to the router table top, then use the router and a straight cutter to cut the groove. A micro positioning device such as the Micro-Fence will enable >ou to match the groove width to your miter gauge bar without moving the straightedge guide. When culling the miter slot, keep in mind that most miter slots are -V« in. deep by -V4 in, wide, but check your miter gauge bar size and cut the groove to match. Oncc the miter groove and the insert hole are cut. use either a fine file (or a bevel cutting laminate trimmer hit) lo apply a slight hevel to the exposed laminate edges all around. This helps minimize the chance of chipping the laminate during use of the router table. Mount Lev tiers To rnoiini the levelers (N). you'll first need to shim under them. We simply made a single-piece cutout of in. plywood to serve as a leveler shim, but you could also just use separate strips of 1/2 in. stock under each leveler. Screw the shim in place with the shim screws (X). Instructions for mounting the levelers are included in your Hardware Kit Add Frame and Make Leg We used oak for our frame and leg parts, but any hardwood will do. Cut the frame parts lo the sizes shown, drill and coun-terbore for the v arious assembly screw s (W). and drill for and mount the machine screws (S) and matching T-nuts (U) ihat are used to secure the leg. Now mount the frame parts as indicated. Next, make the leg. drilling the pair of t holes to match the machine screw s in the frame front. Also, drill for and add the adjustable foot (V). The screw-type foot March/ April 1994 37 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||