Woodworker's Journal 1994-18-3, страница 14

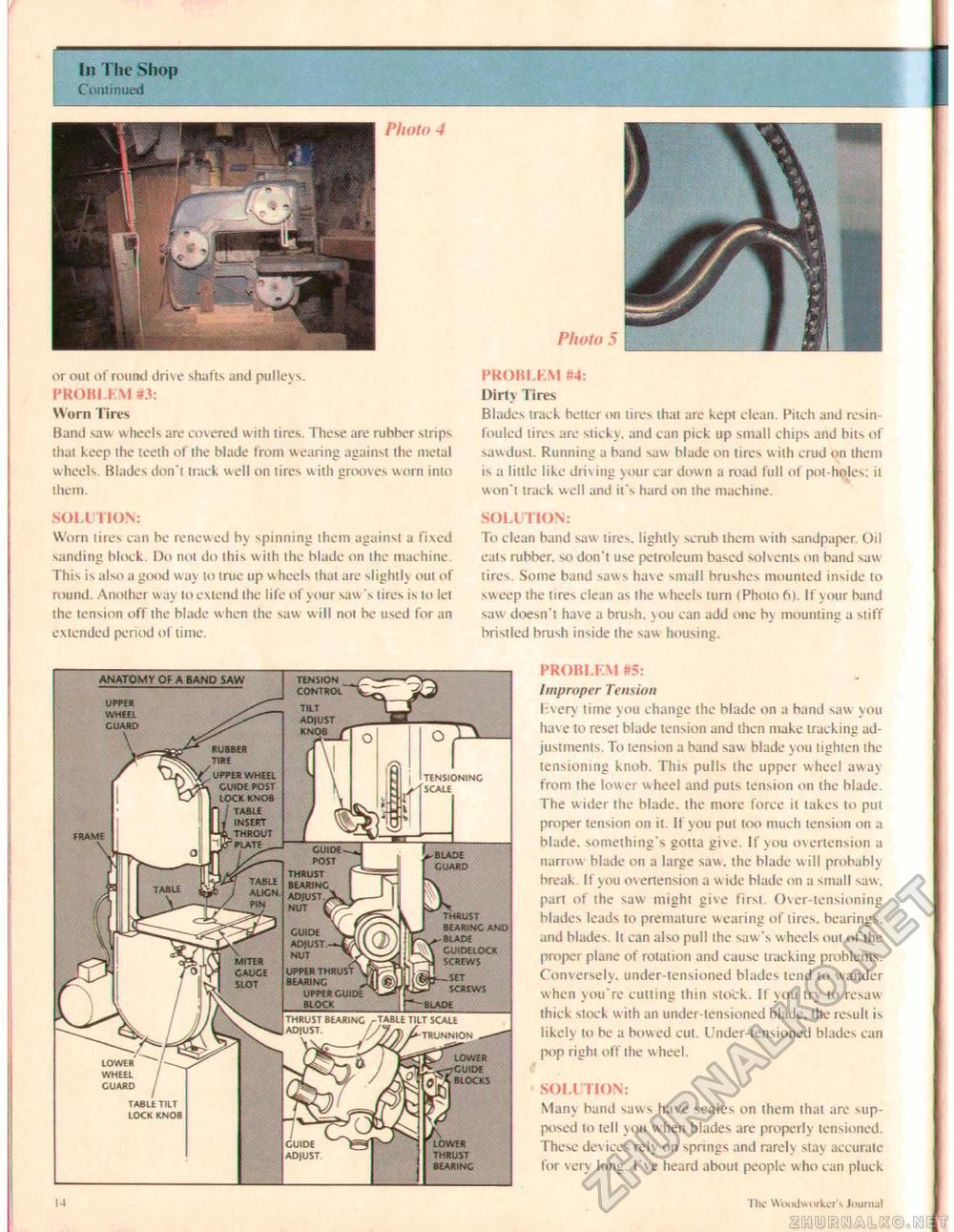

Photo 5 In The Shop Continued Photo 4 or out of round drive shafts and pulley s. PROBLEM #3: Worn Tires Band saw wheels are covered with tires. These are rubber strips that keep the teeth of the blade from wearing against the metal wheels. Blades don't track well on tires with grooves worn into them. SOLUTION: Worn tires can he renewed by spinning them against a fixed sanding block. Do not do this w ith the blade on the machine. This is also a good way to true up wheels that are slightly out of round. Another w ay to extend the life of your saw's tires is to let the tension off the blade when the saw will not be used for an extended period of lime. PROBLEM #4: Dirty Tires Blades track better on tires that are kept clean. Pitch and resin-fouled tires are sticky, and can pick up small chips and bits of sawdust. Running a band saw blade on tires with crtid on them is a little like driving your car dow n a road full of pot-holes; it won't track well and it's hard on the machine. SOLUTION: To clean band saw tires, lightly scrub them with sandpaper. Oil cats rubber, so don't use petroleum based solvents on hand saw tires. Some band saws have small brushes mounted inside to sweep the tires clean as the w heels turn (Photo 6). If your band saw doesn't have a brush, you can add one by mounting a stiff bristled brush inside the saw housing. PROBLEM #5: Improper Tension Every time you change ihe blade on a band saw you have to reset blade tension and then make tracking adjustments. To tension a band saw blade you tighten the tensioning knob. This pulls the upper wheel away from the lower wheel and puts tension on the blade. The wider the blade, the more force it takes to put proper tension on it. If y ou put too much tension on a blade, something's gotta give. If you overtension a narrow blade on a large saw. the blade w ill probably break. If you overtension a wide blade on a small saw. part of the saw might give first. Over-tensioning blades leads to premature wearing of tires, bearings, and blades. It can also pull the saw's wheels out of the proper plane of rotation and cause tracking problems. Conversely, under-tensioned blades tend to wander when you're cutting thin stock. If you try to resaw thick stock with an under-tensioned blade, the result is likely to be a bowed cut. Under-tensioned blades can pop right off the wheel. SOLUTION: Many band saws have scales on them thai are supposed to tell you when blades are properly tensioned. These devices rely on springs and rarely slay accurate for very long. I've heard about people who can pluck 14 The VVi>otJu.iirk<.T Journal |